At KT-Foundry, we understand the crucial role of stainless steel casting in the medical industry. Precision casting utilizing stainless steel investment casting has become increasingly important in the medical field, providing unmatched quality and accuracy in the production of medical equipment and devices.

Stainless steel casting involves pouring molten stainless steel into a mold to create a specific shape or component. It offers several advantages over other casting methods, including its ability to produce intricate designs with superior surface finishes.

When it comes to medical applications, stainless steel casting is highly sought after for its corrosion resistance, strength, and durability. It can withstand harsh environments and is ideal for use in medical equipment and devices that require precision and reliability.

Key Takeaways:

- Precision matters in stainless steel casting for medical applications.

- Stainless steel investment casting offers advantages over other casting methods.

- Stainless steel casting is highly corrosion-resistant, strong, and durable.

- Medical equipment and devices benefit from the precision and reliability of stainless steel casting.

- KT-Foundry is committed to supplying the highest quality stainless steel products for medical and industrial applications.

What is Stainless Steel Casting?

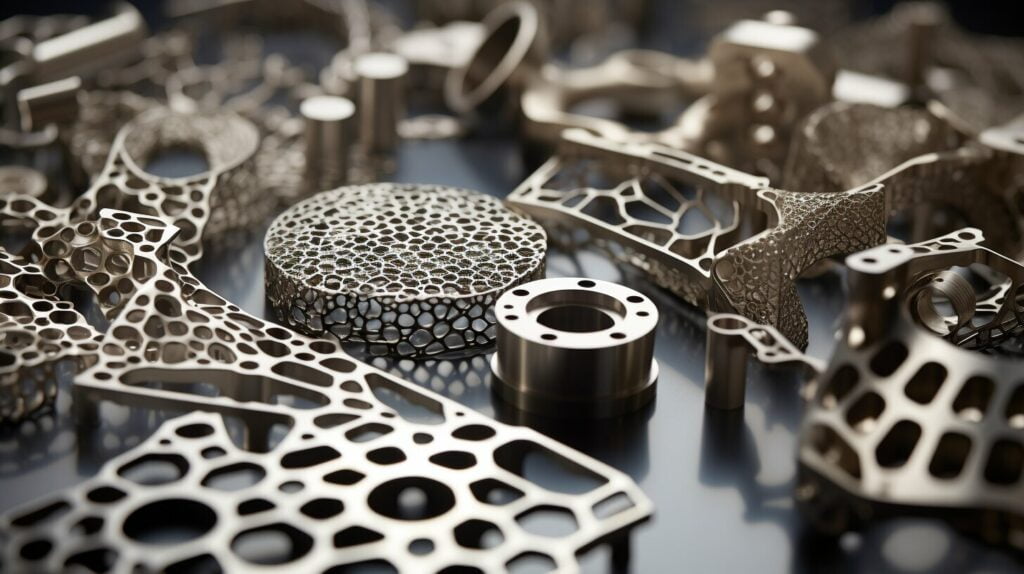

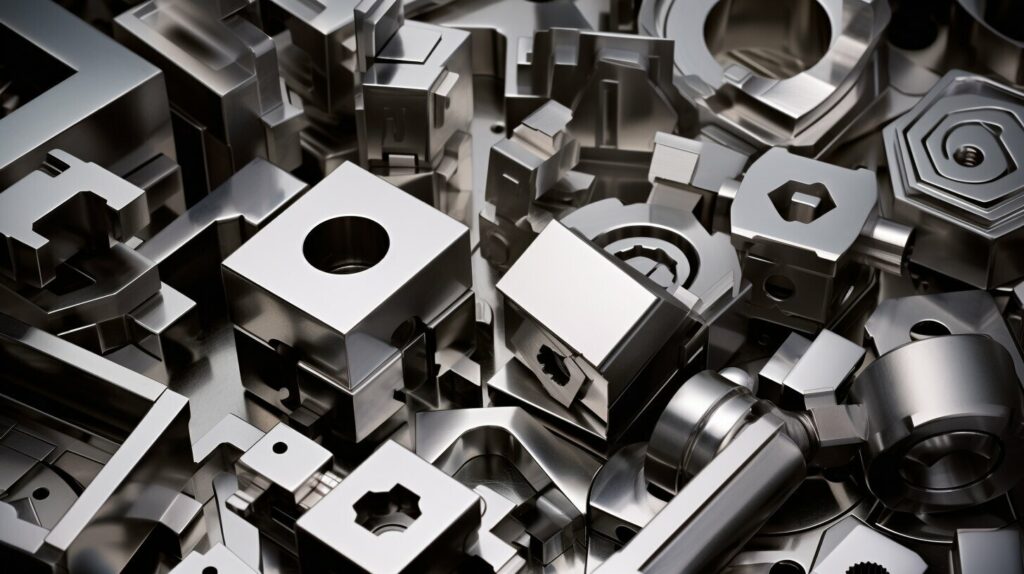

Stainless steel casting is a process used to create complex, intricate parts and components using molten stainless steel. This casting method, also known as investment casting, offers a number of advantages over other casting methods, including the ability to produce parts with exceptional surface quality and dimensional accuracy.

Investment casting involves creating a wax mold of the desired part, coating the wax with a ceramic shell, and then pouring molten stainless steel into the shell. Once the stainless steel has cooled and solidified, the ceramic shell is broken away to reveal the finished part.

Stainless steel investment casting is particularly well-suited to applications where precision and surface finish are critical, such as medical equipment and aerospace components.

At our foundry, we specialize in producing high-quality stainless steel parts and components using the investment casting method. Our team of skilled technicians and engineers have years of experience in the casting industry, and we use the latest in cutting-edge technology to ensure that every part we produce meets your exact specifications and requirements.

Types and Grades of Stainless Steel Used in Casting

Stainless steel alloys are commonly used in precision casting due to their excellent corrosion resistance and durability. The three main types of stainless steel alloys used in casting are austenitic, martensitic, and duplex stainless steel.

Austenitic stainless steel: This type of stainless steel is known for its high ductility and excellent weldability. It contains high levels of nickel and chromium, providing exceptional corrosion resistance in various environments. Austenitic stainless steel is commonly used in medical and food-grade applications.

Martensitic stainless steel: This type of stainless steel is heat-treatable and has high mechanical strength, making it ideal for applications that require high wear resistance. It contains moderate levels of nickel and high levels of chromium, providing excellent corrosion resistance in mildly aggressive environments.

Duplex stainless steel: This type of stainless steel has a mixed microstructure of austenite and ferrite, providing excellent mechanical strength and corrosion resistance. It contains high levels of chromium and moderate levels of nickel, making it suitable for applications that require high strength and corrosion resistance.

Stainless steel grades are further classified based on their chemical compositions and mechanical properties. Stainless steel grades commonly used in casting include 304, 316, 410, and 2205 duplex stainless steel.

At our stainless steel foundry, we specialize in producing precision cast stainless steel components using various types and grades of stainless steel. Our experienced team utilizes advanced casting techniques to ensure the highest quality and precision in every product we manufacture.

Advantages of Stainless Steel Casting in Medical Applications

Stainless steel casting offers numerous advantages for medical equipment and devices, making it a popular choice for manufacturers in the healthcare industry. The precision casting process of stainless steel ensures that medical equipment and devices are produced to exact specifications, resulting in parts that fit seamlessly together and operate efficiently.

One of the primary advantages of stainless steel casting in medical applications is its exceptional corrosion resistance. Medical equipment and devices are often used in harsh environments and exposed to chemicals, making corrosion resistance a crucial factor. Stainless steel casting ensures that medical equipment and devices can withstand exposure to chemicals and harsh conditions without deteriorating over time.

Another advantage of using stainless steel casting in medical equipment and devices is its ability to produce complex and intricate shapes with high accuracy. The precision casting method of stainless steel enables the production of intricate parts and components, which can be difficult to manufacture using other methods.

Stainless steel is also biocompatible, making it an ideal material for medical applications. Medical equipment and devices must be able to interact safely with the human body, and stainless steel casting meets this requirement. Stainless steel is non-reactive, hypoallergenic, and easy to clean, making it an excellent choice for medical devices that come into contact with patients regularly.

Examples of medical equipment and devices that benefit from stainless steel casting include surgical instruments, implantable devices, and diagnostic equipment. The durability, precision, and corrosion resistance of stainless steel casting make it an ideal material for these applications.

At KT-Foundry, we specialize in stainless steel investment casting for medical equipment and devices. Our expert engineers and technicians use the latest precision casting techniques to ensure that every part and component meets the highest standards of quality and accuracy. We are committed to pushing the boundaries of stainless steel casting to provide the best possible solutions for healthcare professionals and patients.

The Stainless Steel Casting Process for Medical Applications

Stainless steel investment casting process is a precise and efficient method of producing intricate components and parts. This process involves the use of a wax pattern that is coated with a ceramic material to form a mold. Molten stainless steel is then poured into the mold, fusing with the ceramic material and solidifying into the desired shape. The ceramic mold is then broken away, leaving behind the final cast stainless steel component.

One of the key advantages of stainless steel investment casting is its ability to produce complex shapes and intricate details with high precision. This precision casting method ensures consistency and accuracy, minimizing the need for costly and time-consuming secondary machining.

Lost wax casting is another common method used in the stainless steel casting process, particularly in the production of small or complex components. This process involves creating a wax model of the desired product and coating it in ceramic material to create a mold. The mold is then heated to melt away the wax, leaving a cavity in the shape of the wax model. Molten stainless steel is poured into the mold, taking on the shape of the cavity and solidifying into the final product.

Both of these casting processes, combined with precision casting, provide unparalleled accuracy, consistency, and reliability in the production of high-quality stainless steel components for medical applications and many other industrial applications.

Stainless steel casting is a pivotal process in the manufacturing of medical equipment and devices. The versatility and reliability of cast stainless steel components and parts make it a preferred material in the medical industry.

Stainless steel products offer unique characteristics such as high-temperature resistance, high strength, and corrosion resistance, making it an ideal choice for various medical devices.

Cast stainless steel components and parts are commonly used in medical equipment such as surgical instruments, orthopedic implants, and dental applications. They are also used in the production of pacemakers, diagnostic machinery, and other medical equipment and devices.

| Medical Devices | Examples |

|---|---|

| Surgical instruments | Scalpels, forceps, scissors, clamps |

| Orthopedic implants | Knee and hip replacements, plates and screws |

| Dental applications | Implants, brackets, orthodontic wires |

| Pacemakers | Implantable pacemakers, cardiac monitors |

| Diagnostic machinery | Magnetic Resonance Imaging (MRI) machines, X-ray machines |

At KT-Foundry, we understand the importance of producing high-quality cast stainless steel components and parts for medical equipment and devices. Our expertise in precision casting, combined with our use of the latest technologies and materials, ensures that we provide the best solutions for our customers’ specific needs.

We offer a wide range of cast stainless steel parts and components, including austenitic, martensitic, and duplex stainless steel grades. Our products are manufactured using the stainless steel investment casting process, providing unmatched precision, consistency, and quality.

At KT-Foundry, we are committed to delivering durable, high-performance stainless steel components and parts for medical devices. Our products are ideal for medical applications due to their exceptional strength, corrosion resistance, and biocompatibility. We strive to maintain a consistent level of quality, reliability, and precision in all our products.

Applications of Stainless Steel Casting Beyond Medicine

While stainless steel casting is widely used in the medical industry for its precision and corrosion resistance, it also has a diverse range of applications in other industries. Industrial applications, marine applications, and composite stainless steel are just a few examples of the many ways in which stainless steel casting is utilized.

At KT-Foundry, we specialize in producing high-quality cast stainless steel components and parts that meet the precise specifications required by various industries. From heavy-duty industrial equipment to marine components that withstand harsh environments, our casting manufacturers are committed to excellence and quality control at every stage of the process.

One example of the versatility of stainless steel casting is its use in marine applications. The ability of stainless steel to resist corrosion in saltwater environments makes it an ideal choice for marine equipment and parts. Additionally, stainless steel’s durability and strength make it a popular choice for industrial applications, where it is used in everything from aerospace components to power generation equipment.

Another area of growth for stainless steel casting is in composite stainless steel. By combining different types of stainless steel alloys, manufacturers can create custom blends that offer unique properties and performance. This flexibility opens up new possibilities for innovation and optimization in a broad range of industries.

Advancements in Stainless Steel Casting for Future Innovations

As a leading stainless steel foundry, we are constantly exploring new materials, casting processes, and custom solutions to push the boundaries of precision casting and meet the evolving needs of our customers. For example, we have developed a composite stainless steel that combines the corrosion resistance of austenitic stainless steel with the strength of martensitic stainless steel, creating a highly durable and versatile material suitable for a wide range of applications.

In addition, we constantly refine our casting processes to ensure maximum efficiency and quality. Our state-of-the-art facilities utilize the latest casting technologies, including vacuum casting and computer-aided design (CAD) systems, to produce intricate and complex stainless steel components with unparalleled precision.

At the same time, we pride ourselves on our ability to provide custom stainless steel solutions tailored to the specific requirements of our clients. Our experienced engineers work closely with customers to develop custom alloys, shapes, and sizes, allowing us to produce stainless steel components that are uniquely suited to their needs.

Looking to the future, we see even greater potential for stainless steel casting in a wide range of industries. From aerospace to automotive to renewable energy, the durability, corrosion resistance, and versatility of stainless steel make it an ideal material for a multitude of applications. As a result, we remain dedicated to pushing the limits of precision casting and delivering the highest quality stainless steel products to our customers.

“Our state-of-the-art facilities utilize the latest casting technologies, including vacuum casting and computer-aided design (CAD) systems, to produce intricate and complex stainless steel components with unparalleled precision.”

Conclusion

In conclusion, we at KT-Foundry understand the critical role that precision casting plays in advancing medical technology and pushing the boundaries of innovation. Our commitment to quality and excellence is reflected in the wide range of stainless steel products we offer for medical and industrial applications.

Our state-of-the-art stainless steel foundry is equipped with the latest casting processes and materials, allowing us to create custom solutions that meet the unique needs of our clients. From medical equipment and devices to industrial and marine applications, we are proud to provide cast stainless steel components and parts that are versatile, durable, and corrosion-resistant.

The Future of Stainless Steel Casting

Looking ahead, we are excited to see the continued advancements being made in the field of stainless steel casting. As technology and materials improve, stainless steel will continue to be a preferred choice for a variety of applications, from medical to industrial and beyond. We at KT-Foundry are committed to staying at the forefront of these developments, and to providing our clients with the highest quality stainless steel products and services.

Thank you for considering KT-Foundry for your stainless steel casting needs. We look forward to working with you in the future.

FAQ

What is the importance of precision in stainless steel casting?

Precision is crucial in stainless steel casting as it ensures the accurate reproduction of complex medical components, leading to enhanced functionality and performance.

What is stainless steel casting and how is it different from other casting methods?

Stainless steel casting is a casting method that uses an investment casting process to create intricate and precise stainless steel components. It offers superior accuracy and surface finish compared to other casting methods.

What are the different types and grades of stainless steel used in casting?

Stainless steel used in casting can include austenitic, martensitic, and duplex stainless steel, each with unique properties and advantages for specific applications.

What are the advantages of using stainless steel casting in medical applications?

Stainless steel casting offers numerous advantages in medical applications, including excellent corrosion resistance, precise casting capabilities, and suitability for medical equipment and devices.

What is the stainless steel casting process for medical applications?

The stainless steel investment casting process involves using lost wax casting to create intricate and precision components for medical applications. It encompasses multiple steps to ensure high-quality casting.

What are some examples of medical equipment and devices that benefit from stainless steel casting?

Stainless steel casting is utilized in a wide range of medical equipment and devices, including surgical instruments, implants, prosthetics, and diagnostic equipment, to name a few.

What are the applications of stainless steel casting beyond the medical field?

Stainless steel casting finds applications in various industrial sectors, marine applications, and other fields where its durability, corrosion resistance, and strength are highly valued.

What advancements are being made in stainless steel casting for future innovations?

Ongoing advancements in stainless steel casting include the use of new materials, the development of advanced casting processes, and the potential for custom stainless steel solutions to meet evolving industry needs.

What role does KT-Foundry play in stainless steel casting?

As a leading stainless steel foundry, KT-Foundry is committed to pushing the boundaries of precision casting and supplying high-quality stainless steel products for medical and industrial applications.