The oil pump is key to a vehicle’s engine, keeping it well-lubricated, cooled, and reducing friction. It’s at the heart of the engine’s lubrication system. This part is vital for the engine’s efficiency and long life.

It moves oil to different parts of the engine. This keeps the engine running smoothly and protects important parts from damage. This helps the engine perform better and makes the vehicle more reliable and longer-lasting.

Key Takeaways

- The oil pump housing is a vital engine component that ensures proper lubrication, cooling, and friction reduction.

- It circulates the engine oil, maintaining optimal working conditions and preventing wear and tear on critical engine parts.

- The oil pump housing’s effectiveness is crucial for the engine’s efficiency and longevity.

- The oil pump housing plays a central role in the engine’s lubrication system, contributing to the overall reliability and performance of the vehicle.

- Understanding the function and importance of the oil pump housing is essential for maintaining a well-functioning engine.

Function of the Oil Pump Housing

The oil pump housing is key to the engine’s lubrication system. It makes sure the engine’s parts work well and last longer. It sends engine oil to parts like pistons, crankshafts, camshafts, and bearings.

Lubrication

This housing helps spread engine oil, making a thin layer that reduces wear. This stops parts from rubbing together, cutting down on friction and wear. This keeps the engine’s parts running smoothly and lasts longer.

Cooling

Engine oil moves around, picking up heat from moving parts. The oil pump housing takes this heat away, keeping the engine at the right temperature. This is key to keeping the engine running well and avoiding damage.

Friction Reduction

The oil pump housing is key in lowering engine friction. It creates a thin oil layer, reducing wear and tear. This means parts last longer and the engine runs better, saving fuel and improving performance.

In short, the oil pump housing is vital for the engine’s lubrication. It supplies oil, controls temperature, and cuts down on friction. These actions are crucial for the engine’s best performance and long life.

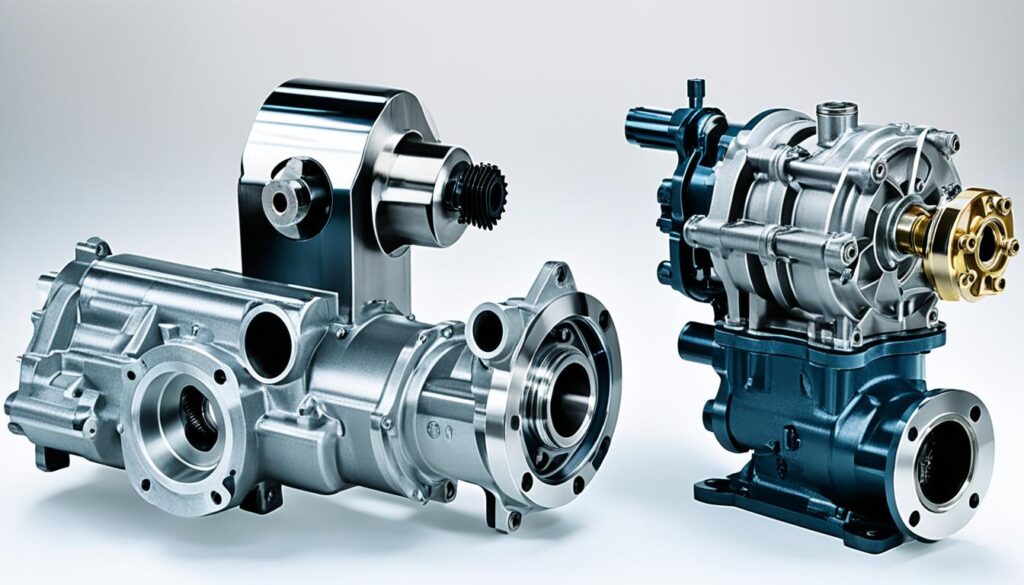

Anatomy of an Oil Pump

Let’s dive into the oil pump’s inner workings. It’s a crucial part of the engine’s lubrication system. It makes sure oil moves around the engine smoothly.

Housing

The housing is the outer shell that holds the oil pump’s parts together. It keeps everything safe and working right. The design can handle the high pressures needed for pumping oil.

Gears or Rotors

Oil pumps use gears or rotors to move and pressurize oil. These parts spin inside the housing. They create a vacuum that pulls oil in and then push it out under pressure. This keeps the engine’s parts well-lubricated.

Suction Pipe/Tube

The suction pipe or tube connects the oil pump to the oil pan. It takes oil from the pan’s bottom and sends it to the pump. This keeps the pump supplied with oil, helping it work well.

These parts work together to keep oil flowing and reaching every part of the engine. This helps the engine run better and last longer.

Types of Oil Pumps

The oil pump is key to keeping our cars running well. It makes sure the engine gets the right amount of lubrication and cooling. There are two main types used in cars: gear oil pumps and rotor oil pumps.

Gear oil pumps have two gears that move together to pull in oil and push it out with more pressure. This helps the oil move around the engine, reducing wear and tear.

Rotor oil pumps, however, use a rotor with vanes to move oil through the pump. They are smaller and make a steady flow of oil, which is why they’re often used in newer engines.

| Gear Oil Pumps | Rotor Oil Pumps |

|---|---|

| Two intermeshing gears | Rotor with multiple vanes |

| Draw in oil through suction side | Sweep oil through internal chambers |

| Push oil out at higher pressure | Create suction and pressure effect |

| Efficient oil circulation | Compact size, consistent flow |

Both gear and rotor oil pumps are crucial for a well-running engine. They make sure all the engine parts get the lubrication and cooling they need.

Oil Pump Housing: Key Component

The oil pump housing is key to the engine’s lubrication system. It supports the oil pump’s parts, making sure oil moves and gets pressurized right. Without it, the engine would overheat and could fail.

This part does many important jobs:

- It keeps the oil pump safe and sound, making sure it draws oil and spreads it around the engine.

- Its design affects how well the pump works and the pressure it makes, which is key for the engine’s performance and life.

- It protects the pump’s parts from harm and dirt, helping the engine run smoothly.

If the oil pump housing doesn’t work right, the engine faces big problems. It might not get enough oil, or it could wear out fast. So, keeping this part in good shape is crucial for the engine’s best performance and life.

| Component | Function |

|---|---|

| Oil Pump Housing | Provides structure and support for the oil pump, ensuring proper oil circulation and pressurization throughout the engine |

| Oil Pump | Draws oil from the sump and distributes it to various engine components, ensuring adequate lubrication |

| Engine Components | Receive the pressurized oil from the pump, reducing friction and wear for optimal engine performance and longevity |

Knowing how vital the oil pump housing is helps us see why regular checks and timely replacements are a must. They prevent engine damage and keep the car reliable.

Signs of a Failing Oil Pump

The oil pump is key to your car’s engine, making sure it’s well-lubricated. If it fails, it can cause big problems for your engine. Here are signs your oil pump might be on the fritz:

Engine Misfiring

A bad oil pump can make your engine misfire. This happens because it doesn’t lubricate well and parts rub together too much. This leads to poor combustion and cylinders misfiring.

Engine Noise

When the oil pump fails, it doesn’t circulate oil enough. This means parts rub together more, causing noise. You might hear tapping or knocking sounds, especially when starting the engine or under heavy load.

Drop in Oil Pressure

A sudden drop in oil pressure while the engine runs means the oil pump might be broken. This can hurt your engine if you don’t fix it.

It’s crucial to fix oil pump issues quickly to protect your engine. Regular checks and maintenance can catch problems early.

| Symptom | Cause | Potential Consequence |

|---|---|---|

| Engine Misfiring | Inadequate lubrication and increased friction | Poor combustion, cylinder misfiring |

| Engine Noise | Insufficient oil circulation, increased friction | Tapping or knocking noise, especially at startup or under load |

| Drop in Oil Pressure | Oil pump not functioning properly | Potential engine damage if left unaddressed |

Knowing these signs and acting fast can keep your car’s engine running well.

Oil Pressure Regulation

The oil pump is key for making sure the engine oil moves and lubricates properly. It must work with the right pressure to avoid harming the pump and other engine parts.

A vital part in managing this pressure is the pressure relief valve. It opens when oil pressure gets too high. This lets out the extra pressure to keep the engine safe.

The oil pump pushes the oil around, but the valve keeps the pressure in check. If pressure gets too high, the valve opens to release it. This keeps the pump and other parts from getting damaged.

Understanding the Pressure Relief Valve

The pressure relief valve is usually found near the oil pump or inside the pump. It watches the oil pressure and acts to keep it at the right level. If pressure gets too high, it opens to let out the extra and send it back to the oil sump.

| Component | Function |

|---|---|

| Pressure Relief Valve | Regulates oil pressure by opening to release excess pressure and prevent damage to the engine |

| Oil Pump | Generates the necessary pressure to circulate the engine oil |

With the right oil pressure, thanks to the pressure relief valve, the engine works better. It gets the right lubrication, moves smoothly, and performs well. This valve is key to keeping the engine running long and efficiently by stopping high pressure damage.

Conclusion

The oil pump housing is key to the engine’s lubrication system. It makes sure the engine oil moves and gets pressurized. This helps with lubrication, cooling, and reducing friction. These are crucial for the engine to work well and last longer.

Signs like engine misfiring, noise, and lower oil pressure mean the oil pump might be failing. Spotting these signs early helps avoid engine failure and keeps it running right.

This article covered the oil pump housing’s important functions and its parts. We looked at the different oil pumps out there. We also talked about how oil pressure works and what to watch for if the oil pump is failing.

Understanding the oil pump housing helps us keep our engines running smoothly and efficiently. By taking care of this important part, we can make our engines last longer and perform better.

In short, the oil pump housing is a must-have for a healthy engine. Taking good care of it ensures our engines work well, giving us the power and reliability we need from our vehicles.

FAQ

What is the primary function of the oil pump?

The main job of the oil pump is to send engine oil to parts like pistons and bearings. This oil acts as a lubricant, reducing wear and friction between components.

How does the oil pump help with engine cooling?

The oil pump moves oil around the engine, taking heat away from moving parts. This helps keep the engine at a safe temperature, preventing overheating.

How does the oil pump reduce friction in the engine?

By creating a thin oil layer between moving parts, the oil pump cuts down on friction. This helps extend the life of engine components and keeps the engine running smoothly.

What are the main types of oil pumps used in cars?

Cars use two main types of oil pumps: gear and rotor pumps. Gear pumps use intermeshing gears to draw and push oil. Rotor pumps have a rotor with vanes that move oil through the pump.

What is the role of the oil pump housing?

The oil pump housing is key to the engine’s lubrication. It supports the pump’s parts, ensuring oil flows and is pressurized correctly. Without it, the engine would overheat and could fail.

What are the signs of a failing oil pump?

A failing oil pump can cause engine misfires and increased friction. This leads to poor combustion and noise from the engine. A sudden drop in oil pressure is also a sign of a problem.

How does the oil pressure relief valve work?

The oil pump builds pressure to move oil, but a relief valve controls this. If pressure gets too high, the valve opens to prevent damage to the pump and other parts.