At KT-Foundry, we are dedicated to providing high-performance rotary welding tables that enhance productivity and quality in various welding applications. Our focus is on delivering efficient and precise solutions to meet the diverse needs of our customers. By leveraging the latest advancements in welding table technology, we strive to empower welders and fabricators to achieve exceptional results in their projects.

Key Takeaways

- KT-Foundry specializes in manufacturing high-quality rotary welding tables

- Our products are designed to enhance productivity and precision in welding applications

- We leverage the latest advancements in welding table technology to deliver efficient solutions

- Our goal is to empower welders and fabricators to achieve exceptional results

- We are committed to providing reliable and durable rotary welding tables to our customers

Introduction to Rotary Welding Tables

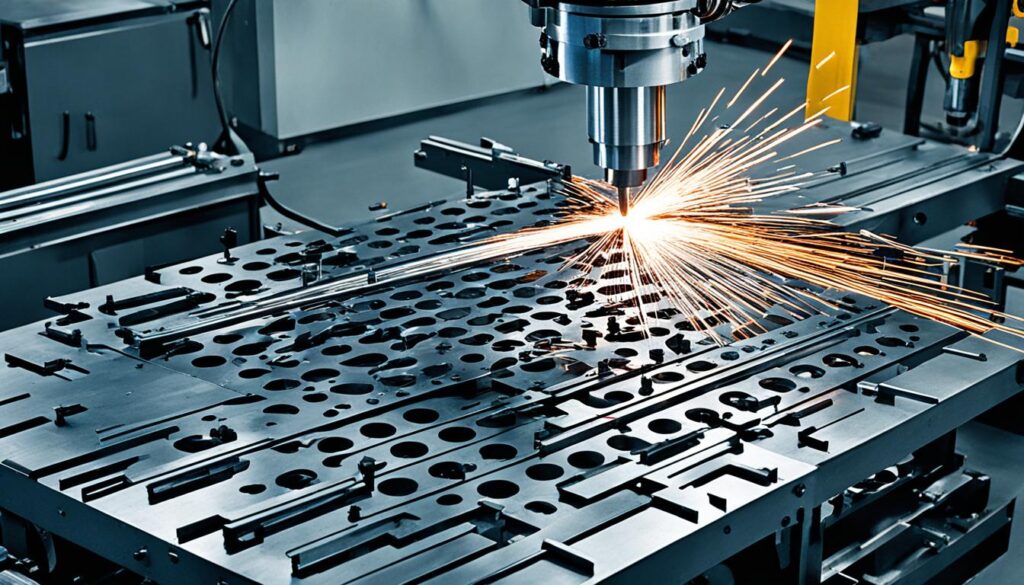

Rotary welding tables, also known as circular welding positioners or turntable welding fixtures, are specialized equipment designed to enhance the welding process. These versatile tables allow for the controlled rotation of the workpiece around its own axis, providing the welder with easy access to the entire weld surface. By enabling the workpiece to be rotated, rotary welding tables contribute to improved weld quality, increased efficiency, and greater consistency in the welding operation.

Definition and Overview

A rotary welding table is a circular platform that can be rotated to facilitate the welding of various workpieces. These tables, also known as welding turntables or rotating welding platforms, are an essential tool in many welding applications, enabling seamless access to the entire weld area.

Benefits of Using Rotary Welding Tables

Rotary welding tables offer numerous advantages to welders and fabricators. They enhance accuracy and repeatability by allowing for precise control over the rotational speed and angle of the workpiece, ensuring consistent and uniform welds. Additionally, the ability to rotate the workpiece around its axis enables the welder to access the entire weld surface, leading to improved weld joint uniformity and stability. By streamlining the welding process, rotary welding tables can significantly boost productivity and efficiency, making them a valuable investment for any welding operation.

- Improved weld quality and consistency

- Enhanced accessibility to the entire weld surface

- Increased productivity and efficiency

- Precise control over rotational speed and angle

Whether you’re working with a circular welding table, a revolving welding stand, or a rotary welding manipulator, these versatile tables can revolutionize your welding process and take your fabrication to new heights.

Features of Rotary Welding Table from KT-Foundry

At KT-Foundry, we take pride in designing rotary welding tables that prioritize precision, versatility, and durability. Our commitment to crafting exceptional products is reflected in the remarkable features that set our tables apart.

Precision and Accuracy

Utilizing top-tier inverter-controlled motors, our rotary welding tables allow for smooth and precise adjustment of the rotational speed, ensuring consistent and repeatable welds. The compact and solid construction of our devices provides convenient access to the processed element, enabling the welder to work with a high degree of precision and comfort.

Versatility and Adjustability

The rotary welding tables from KT-Foundry are designed with a high degree of versatility and adjustability to accommodate a wide range of welding projects. The adjustable start and smooth braking on fluid rotations, combined with the ability to rotate the worktable in both directions, provide the user with enhanced control and flexibility. The compact and modular design of our tables allows for easy integration into various welding environments, making them a valuable asset for welding professionals.

Durability and Longevity

KT-Foundry’s rotary welding tables are built to withstand the demands of a professional welding environment. Utilizing high-strength cast iron EN-GJL-300 for the tabletop, our tables are known for their exceptional wear resistance and durability. The 25mm thick tabletop ensures the table’s longevity and resistance to mechanical damage, making it a reliable choice for welding professionals who require a robust and long-lasting solution.

Applications of Rotary Welding Tables

Rotary welding tables from KT-Foundry are versatile tools that find a wide range of applications across various industries. These innovative products are instrumental in facilitating precise and efficient welding processes, making them an invaluable asset for professionals in the automotive, aerospace, heavy machinery, and fabrication sectors.

One of the primary advantages of using a rotary welding table, such as a circular welding positioner or turntable welding fixture, is the ability to control the rotation of the workpiece. This feature allows welders to achieve consistent and uniform welds, ensuring high-quality results that meet the stringent standards of their respective industries.

In the automotive industry, rotary welding tables are commonly used for welding chassis components, body panels, and other intricate parts. The rotating welding platform or revolving welding stand ensures that the workpiece can be easily maneuvered, allowing welders to access all angles and deliver seamless, high-quality welds.

Similarly, in the aerospace industry, rotary welding positioners and circular welding tables play a crucial role in the fabrication of aircraft components, where precision and accuracy are paramount. These specialized welding tables enable welders to consistently produce flawless welds, contributing to the overall structural integrity and safety of the aircraft.

Beyond these industries, rotary welding tables from KT-Foundry find applications in the fabrication of heavy machinery, industrial equipment, and a wide range of other products that require reliable and consistent welding processes. The rotary welding manipulator or welding turntable allows welders to effortlessly rotate and position the workpiece, ensuring optimal accessibility and resulting in high-quality, uniform welds.

Regardless of the industry or application, the versatility and precision offered by rotary welding tables from KT-Foundry make them an indispensable tool for welders and fabricators who demand the highest standards of quality and efficiency in their work.

Conclusion

In conclusion, the rotary welding tables from KT-Foundry offer a comprehensive solution for welding professionals who strive for precision, efficiency, and versatility in their work. By leveraging the latest advancements in welding table technology, our products are designed to enhance the welding process, improve productivity, and deliver consistently high-quality results. Whether you’re working on small-scale projects or tackling large-scale industrial applications, KT-Foundry’s rotary welding tables, circular welding positioners, turntable welding fixtures, rotary welding positioners, welding turntables, rotating welding platforms, rotary welding manipulators, circular welding tables, or revolving welding stands are the reliable and innovative choice for your welding needs.

Our rotary welding tables seamlessly integrate advanced features, including precision and accuracy, versatility and adjustability, and unparalleled durability and longevity. This combination of cutting-edge technology and robust engineering ensures that you can tackle a wide range of welding tasks with confidence, from intricate fabrication work to heavy-duty industrial applications.

By investing in KT-Foundry’s rotary welding solutions, you’ll unlock a new level of efficiency, quality, and control in your welding operations. Experience the difference that our innovative products can make in streamlining your workflow, enhancing your productivity, and delivering superior welding outcomes. Trust KT-Foundry to be your partner in elevating your welding capabilities to new heights.

FAQ

What are the key benefits of using rotary welding tables?

Rotary welding tables enhance accuracy and repeatability, enable access to the entire weld surface, and streamline the welding process, leading to improved weld quality, increased efficiency, and greater consistency.

How do the rotary welding tables from KT-Foundry ensure precision and accuracy?

KT-Foundry’s rotary welding tables utilize top-tier inverter-controlled motors that allow for smooth and precise adjustment of the rotational speed, ensuring consistent and repeatable welds.

What features make the KT-Foundry rotary welding tables versatile and adjustable?

The adjustable start, smooth braking on fluid rotations, and the ability to rotate the worktable in both directions provide users with enhanced control and flexibility. The compact and modular design also allows for easy integration into various welding environments.

How is the durability and longevity of KT-Foundry’s rotary welding tables ensured?

KT-Foundry’s rotary welding tables are built with a 25mm thick tabletop made of high-strength cast iron EN-GJL-300, ensuring exceptional wear resistance and durability to withstand the demands of a professional welding environment.

In what industries can the rotary welding tables from KT-Foundry be applied?

KT-Foundry’s rotary welding tables find a wide range of applications in industries such as automotive, aerospace, heavy machinery, and fabrication, where precise and efficient welding is paramount.