As industrial experts, we know how crucial agitator impellers are. They make sure mixing processes work well. These key players help move energy from the motor to the fluid. This creates the right flow and shear for many industrial tasks.

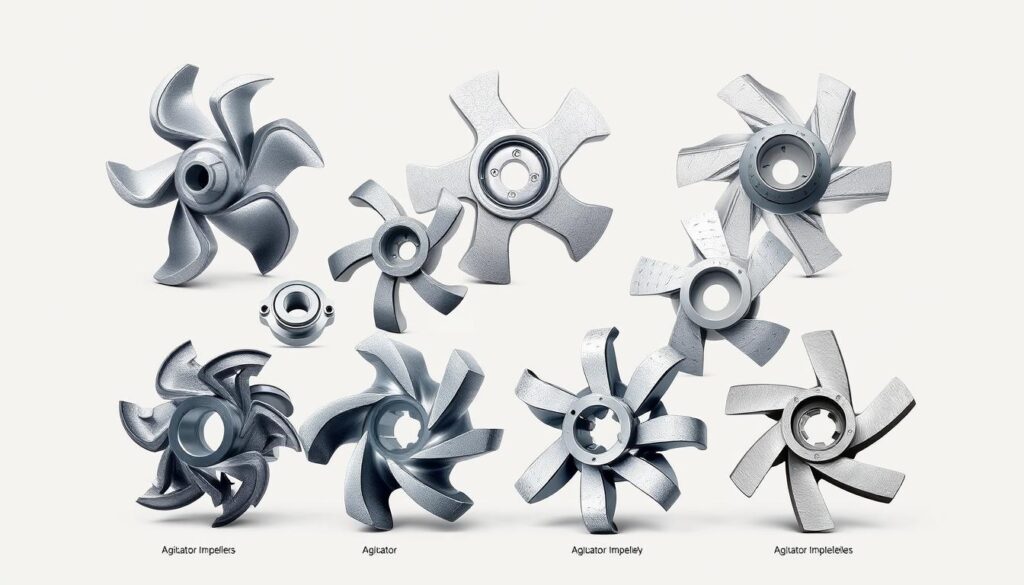

We’ll look at the different types of agitator impellers. Each has its own strengths and uses. From the classic Rushton turbine impeller to the versatile pitched blade turbine and the efficient hydrofoil, there’s a lot to explore. We’ll also cover the anchor impeller, the classic propeller impeller, and the innovative high-efficiency and shear-enhancing designs.

By understanding these impeller types, we can make better choices. This leads to better mixing, less energy use, and higher product quality.

Key Takeaways

- Agitator impellers are crucial components responsible for transferring energy from the motor to the fluid being mixed.

- There are various types of impellers, each with unique characteristics and best-suited applications.

- Understanding the strengths and weaknesses of different impeller designs is essential for selecting the optimal solution for specific mixing needs.

- Proper impeller selection can lead to improved efficiency, reduced energy consumption, and better product quality.

- This guide provides an expert-level overview of the most common types of agitator impellers, including Rushton turbine, pitched blade turbine, hydrofoil, anchor, propeller, high-efficiency, and shear-enhancing designs.

Introduction to Agitator Impellers

At the heart of centrifugal pumps and agitators is a key part called the impeller. It’s a rotating disk with curved blades. It turns the motor’s energy into kinetic energy, moving the fluid outward.

The impeller creates a vacuum. This pulls the fluid into the center, increasing its pressure and flow rate. It’s crucial for the performance and efficiency of mixing equipment.

Defining Agitator Impellers

An impeller is a key part of centrifugal pumps and agitators. It’s the heart of these machines. An impeller turns mechanical energy into kinetic energy, helping to move and mix fluids.

The design and placement of the impeller are key. They determine how well impellers work and their impeller function in centrifugal pumps.

Impellers vary in shape and size, meeting different needs. Their flexibility makes them essential in many industries. This includes residential water management and large industrial uses.

“The impeller is the heart of the centrifugal pump, responsible for generating the flow and pressure that drive the system.”

Varieties of Agitator Impeller Designs

Agitator impellers come in many designs, each with special features. From open to closed impellers, knowing their differences is key. This helps pick the best one for your mixing needs.

Open Impellers

Open impellers have vanes on a central hub, without a shroud. They’re easy to clean but less efficient. They’re great for places where easy access and gentle mixing are important, like in food and drink.

Closed Impellers

Closed impellers have vanes in a shroud. This design boosts efficiency and works well with solids. They’re perfect for industries needing high shear and better liquid flow, like chemical and wastewater.

There are also semi-open, recessed, and vortex impellers. Each has unique features for different mixing challenges. The right impeller depends on the fluid, mixing needs, and system setup.

“Selecting the right agitator impeller design is crucial for achieving optimal mixing performance and efficiency in your process.”

Knowing about types of agitator impellers and their impeller design features helps make the right choice. This ensures your mixing needs are met and your application succeeds.

Conclusion

Choosing the right agitator impeller is crucial. We need to think about flow rate, head, and specific gravity. Also, viscosity and solids content matter a lot.

The impeller design should match the application for the best results. This ensures good performance, energy use, and product quality.

The size of the impeller also plays a big role. It affects flow rate and energy use. Finding the right balance is key.

By carefully picking the agitator impeller, we make mixing better and more efficient. This focus on detail helps keep product quality high. It also cuts down on energy use, boosting our success.

Learn more about how to choose the right agitator impeller here.

FAQ

What is the role of an impeller in an agitator?

The impeller is key in an agitator. It takes energy from the motor and moves it to the fluid being mixed. It’s a spinning disk with curved blades that pulls fluid in and pushes it out, boosting its pressure and flow.

What are the different types of agitator impeller designs?

There are many agitator impeller designs. You have open, closed, semi-open, recessed, and vortex impellers. Each design fits different needs and fluid types.

How do we select the appropriate agitator impeller for a specific application?

Choosing the right impeller involves looking at several factors. These include flow rate, head, specific gravity, viscosity, and solids content. The impeller design should match the application for the best results.

How does the impeller diameter impact the performance of the agitator?

The impeller’s diameter affects flow rate and energy use. It’s important to find a balance between mixing needs and energy efficiency when picking the right size.

What are the advantages and disadvantages of different impeller designs?

Open impellers are simple to clean but less efficient. Closed impellers are more efficient and work well with fluids that have solids. Other designs, like semi-open and vortex, are specialized for specific mixing tasks.