Bearing housing pumps are key in industrial machinery, crucial for keeping systems running smoothly. They do many important jobs. They help align and support the bearings, hold lubricating oil or grease, and cool down the system.

The design and upkeep of the bearing housing greatly affect the pump’s reliability and life. This makes it vital to understand how they work and how to take care of them.

Key Takeaways

- Bearing housing pumps are essential for the efficient operation of industrial machinery.

- The bearing housing plays a crucial role in supporting and aligning the bearings, lubricating the system, and dissipating heat.

- Proper design and maintenance of the bearing housing can significantly impact the overall reliability and lifespan of the pump.

- Understanding the importance of bearing housing components and their configurations is crucial for ensuring optimal pump performance.

- Regular inspection and maintenance of the bearing housing are essential for preventing issues and extending the pump’s lifespan.

Introduction: Understanding Bearing Housing Pumps

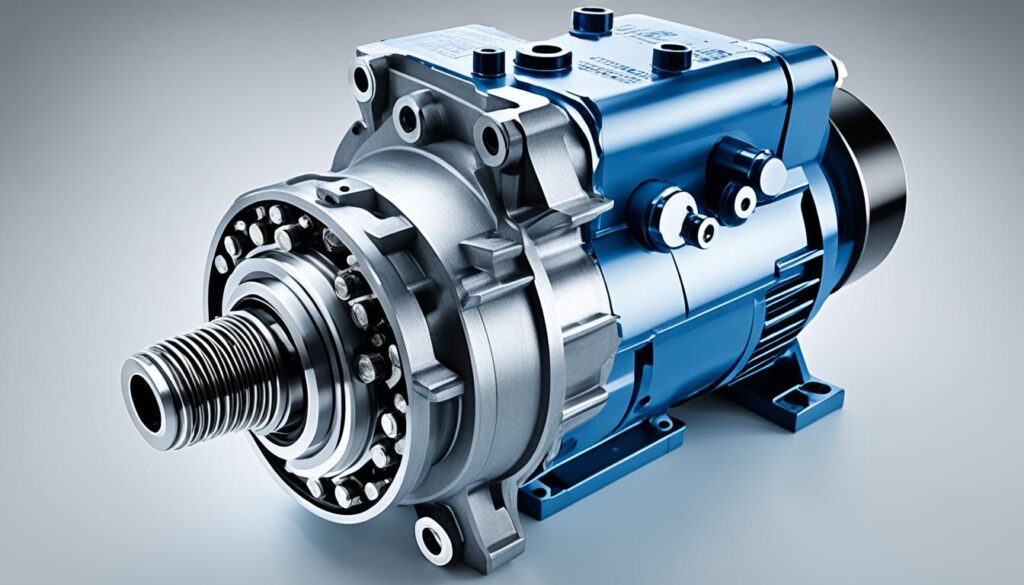

Bearing housings are key to pump systems, making sure they work well and last long. They protect the bearings that support the pump’s shaft and rotor. This keeps everything running smoothly and prevents early failure.

Importance of Bearing Housing in Pump Performance

The bearing housing does many important jobs. It keeps the bearings safe from dirt and helps cool them down. This means the bearings stay in good shape and work right, making the pump run better and last longer.

Overview of Bearing Housing Components

A bearing housing has the housing itself, the bearings, and a system for lubrication. The housing keeps oil or grease that keeps the bearings running smoothly. It also has vents, drains, and taps for adding more lubricant. The design of the shaft, impeller, and bearings is also key for the pump’s performance.

| Component | Function |

|---|---|

| Housing | Typically made of cast iron, the housing provides a protective enclosure for the bearings and helps dissipate heat. |

| Bearings | The bearings, either rolling element or journal-type, support the shaft and rotor assembly. |

| Lubrication System | The housing holds a reservoir of oil or grease that lubricates the bearings, ensuring smooth operation. |

| Shaft and Impeller | The shaft, impeller attachment, and bearing configuration are critical elements of the bearing housing design. |

“Proper design and maintenance of the bearing housing are essential for optimizing pump performance and reliability.”

Bearing Selection and Configurations

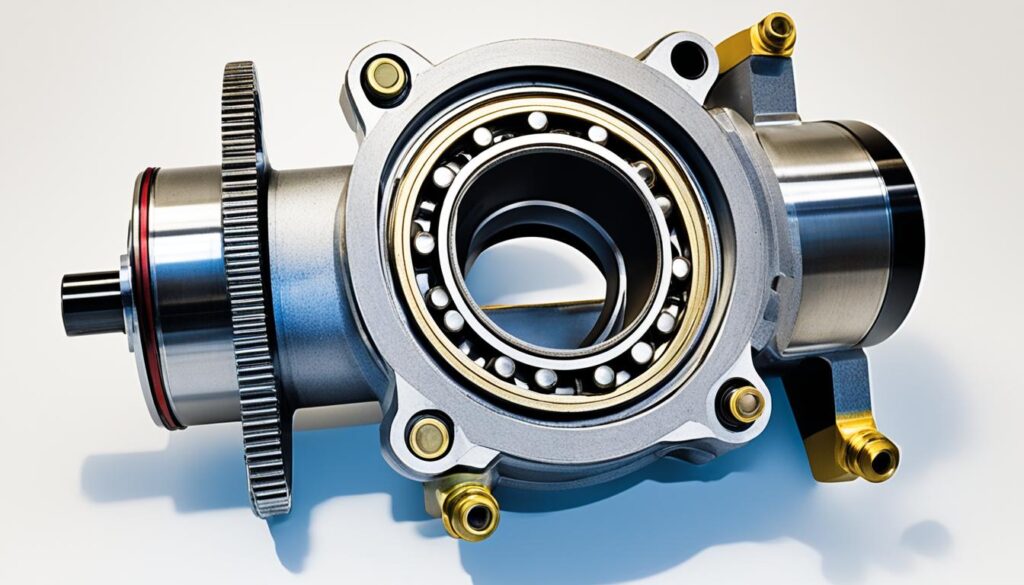

Choosing the right bearings for pump housing is key to good performance and a long life. Pumps use radial and axial bearings to support the shaft and rotor.

Radial vs. Axial (Thrust) Bearings

Radial bearings support radial loads and let the shaft spin easily. Axial bearings handle the forces from the pump impeller. Choosing the right bearings is vital for even load distribution and longer life.

Bearing Types and Materials

Common bearings in pump housings are ball and roller bearings. Ball bearings work well with both radial and axial loads. Roller bearings handle more radial load but less axial load.

Bearings are made of carbon steel, stainless steel, or ceramic. The choice depends on the pump’s conditions, like the fluid, speed, and temperature. Picking the right material is key for durability and reliability.

| Bearing Type | Radial Load Capacity | Axial Load Capacity | Common Materials |

|---|---|---|---|

| Deep-groove Ball Bearings | Moderate | Moderate | Carbon Steel, Stainless Steel |

| Angular Contact Ball Bearings | Moderate | High | Carbon Steel, Stainless Steel |

| Cylindrical Roller Bearings | High | Low | Carbon Steel, Stainless Steel |

Choosing the right bearings is crucial for pump performance and longevity. Knowing the differences between radial and axial bearings helps designers make the best choices for their needs.

Installation and Alignment of Bearing Housings

Putting the bearing housing together right is key for the pump to work well and for the bearings to last longer. There are important steps to follow during the installation.

Proper Installation Techniques

For a good bearing housing install, you need to follow the best methods. Make sure the shaft and bearing fit just right, with a tight inner race and a bit of space for the outer race. Sometimes, you might need to heat the bearings to put them in, and a bearing puller is best for taking them out.

It’s also vital to line up the bearing housing with the pump and shaft correctly. This stops early bearing failure from too much load or vibration. If it’s not lined up right, the bearings can wear out too soon.

Shaft Alignment and Clearance Requirements

Getting the shaft aligned right is key for the pump and the bearing housing to work well. The shaft needs to match up with the housing to spread the load evenly and cut down on vibration. For single-row bearings, the tolerance is 0.0015 to 0.002 inches of movement. For double-row bearings, it’s 0.002 to 0.003 inches. If it’s not aligned, the bearings can wear out too fast.

| Bearing Type | Axial End Play Tolerance |

|---|---|

| Single-row Bearings | 0.0015 to 0.002 inches |

| Double-row Bearings | 0.002 to 0.003 inches |

By following these steps for installing the bearing housing and aligning the shaft, you’ll make sure your pump works great and your bearings last longer.

Lubrication and Maintenance of bearing housing pump

Keeping the bearing housing well-lubricated and maintained is key to a pump’s performance and reliability. The bearings get lubricated with oil or grease. It’s important to keep the oil level right to stop churning and foaming.

Make sure the oil level sits at the mid-ball height of the bearings. Watch the bearing temperatures closely. If they go above 185°F, it could mean a problem that needs looking into.

For grease-lubricated bearings, use the right amount of grease. Too much grease can cause temperature issues. So, pay attention to how much grease you apply.

A good maintenance plan includes regular checks, oil changes, and replacing bearings when needed. This keeps the pump reliable and extends its life. It also keeps it running well for a long time.

| Lubrication Type | Recommended Maintenance |

|---|---|

| Oil Bath |

|

| Grease |

|

By following best practices for lubrication and maintenance, you can ensure your bearing housing pumps work well and last longer. This makes them more efficient and reliable.

Troubleshooting Common Issues

Bearing failures often lead to pump problems. Issues like too much load, not enough lubrication, dirt, and misalignment are common. Signs of bearing trouble include more vibration, strange noises, and higher temperatures. Fixing these problems might mean changing the bearing setup, better lubrication, or replacing bearings. It’s key to find the real cause to stop future issues.

Identifying and Resolving Bearing Failures

Spotting the cause of bearing failures is crucial. Look at how loads are spread, the quality of lubrication, and if things are properly aligned. Once you know the problem, you can fix it. This could mean changing the bearing setup, better lubrication, or replacing old bearings.

Addressing Oil Contamination and Discoloration

Oil issues in the bearing housing can also cause early bearing failure. Dirt, moisture, too much heat, or lubricant breakdown can be the culprits. To fix this, find the root cause by checking the design, lubricant choice, and how things are maintained. Using better filters, changing oil, and adding special passages can help.

Fixing common problems like bearing failures and oil issues keeps your pump systems running well. Always do a deep dive to find the real cause to avoid future problems. This ensures your bearing housing pumps work at their best.

Conclusion

Bearing housing pumps are key in industrial machinery. They need the right design, setup, and upkeep for good performance. Knowing how to pick bearings, lubricate them, and align them helps keep pumps running well.

Keeping ahead of maintenance and fixing issues early is key to avoiding downtime. By following best practices in managing bearing housing pumps, teams can make sure their equipment works well. This cuts down on energy use and makes their important machines last longer.

Staying up-to-date with the latest in bearing housing pump tech is important. Regular checks and maintenance help protect a company’s productivity and profits. With a good grasp of these pumps, experts can handle any problems. This keeps everything running smoothly and keeps costs down.

FAQ

What are the key functions of the bearing housing in a pump?

The bearing housing does many important jobs. It keeps the bearings aligned and supported. It also holds lubricating oil or grease and helps cool the pump.

How the housing is designed and maintained affects the pump’s reliability and life.

What are the common types of bearings used in pump bearing housings?

Deep-groove ball bearings, angular contact ball bearings, and cylindrical roller bearings are common. Ball bearings handle both radial and axial loads well. Roller bearings, like cylindrical ones, can take more radial load but not as much axial load.

How important is proper alignment of the bearing housing and shaft?

It’s crucial to align the bearing housing right with the pump and shaft. This prevents early bearing failure from loads and vibrations. The alignment should be close, with tolerances of 0.0015 to 0.002 inches for single-row bearings and 0.002 to 0.003 inches for double-row ones.

Bad alignment can cause bearings to fail early by putting too much pressure on them.

What are the key considerations for proper lubrication and maintenance of the bearing housing?

Keeping the bearing housing well-lubricated and maintained is key for good pump performance and reliability. Use oil or grease for lubrication, keeping the oil at the right level to avoid problems.

Regular checks, oil changes, and replacing bearings when needed are important. This keeps the pump running smoothly.

How can common bearing housing issues be identified and resolved?

Bearing failures are a big problem for pumps. Issues like too much load, not enough lubrication, dirt, or misalignment can cause trouble. Signs of problems include more vibration, strange noises, and higher bearing temperatures.

To fix these, you might need to adjust the bearings, improve lubrication, or replace them. Oil that’s dirty or looks off can also cause bearings to fail early. Finding and fixing the cause is important.