When it comes to custom part manufacturing, you have a good amount of options to choose from—including cast iron.

But can you forge cast iron or are all parts that require the forging process made from steel or iron? It’s a pretty common question and something we’re asked about quite often.

In this article, we’ll answer your questions about forged cast iron products.

What is casting?

Casting is a manufacturing process that involves using a mold to shape liquid metal into a specific form.

The mold is made of sand, ceramic, or other material and has a hollow cavity that can be filled with molten metal.

Casting is used for making metal parts for machine tools, automobiles, and other vehicles, construction equipment, and many other applications.

What is forging?

Forging is a metalworking process that involves the shaping of metal by plastic deformation. It may be performed cold or hot, depending on the type of metal being forged.

Forging can be done on a blacksmith’s anvil, or it can be done by hammering the workpiece with a mechanical hammer in a machine called a press.

Forging often results in improved performance of the parts, since it hardens and toughens the piece.

The difference between casting and forging?

The difference between the casting process and the forging process is that in casting, the melted metal (known as a “cast”) is poured into a mold, which is then allowed to cool and solidify. The entire part is made from one cast.

In forging, a piece of metal (usually steel) is heated until it becomes malleable, then shaped by hammering or rolling on an anvil. The parts are made individually by hand.

In short, parts made by casting can be stronger than those made by forging because they are made from a single cast of molten metal instead of being forged from individual pieces of steel.

An example of a product made by casting is the famous cast iron pan.

Can you forge cast iron?

No, you cannot forge cast iron. As its name suggests, it is made through the casting process.

Can you forge wrought iron?

While it is impossible to forge cast iron, it is possible to create forged iron with wrought iron. This can be done by heating and hammering wrought iron until it becomes malleable.

If you have a piece of wrought iron that has been forged, the difference between it and cast iron is pretty obvious.

Can you cast steel?

Yes, you can cast steel. Casting steel is a process in which liquid steel is poured into a mold and allowed to cool.

This results in a shape that can be used for many different purposes. The most common uses of cast steel are for the construction of buildings, bridges, and ships.

Casting steel is used for many different types of structures including buildings, bridges, and ships. It can also be used in construction equipment like cranes and bulldozers as well as automobiles such as trucks and tractors.

Can you forge steel?

Yes, you can forge steel. The basic process for forging steel is the same as for forging any other kind of metal.

The only difference is that steel is harder than most other metals and requires more force to work with.

Creating forged steel will require a stronger hammer, as well as a long time spent heating up the metal before you start working on it.

Difference Between Cast Iron and Cast Steel

Steel has a lower melting point than iron.

How to turn ordinary steel plates into high-quality forging materials in China?

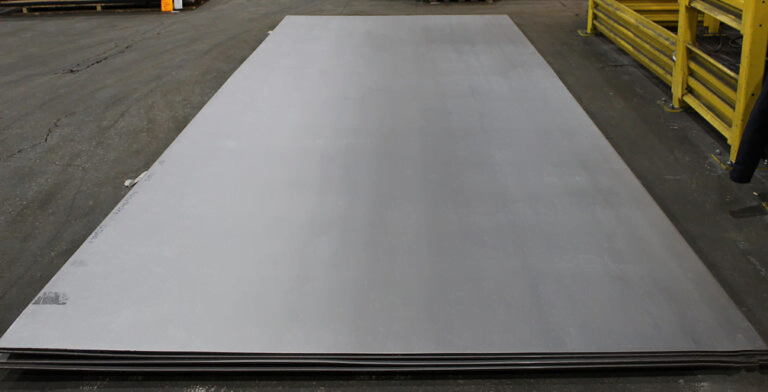

The first step in turning your ordinary steel plates into high-quality forging materials is choosing the right type of plate for your needs.

The selection includes cold-rolled steel plates, hot-rolled steel plates, galvanized steel plates, stainless steel plates, and more.

You must also choose the thickness of your steel from 0.01mm to 4mm so you can find whatever works best for your needs.

When selecting a plate thickness, keep in mind that heavier plates tend to be stronger but may be harder to bend or form into shape as needed during manufacturing processes such as bending/forming or deep-drawing operations where thin wall thicknesses are required for optimal performance under heavy loads (i.e., higher tensile strength level).

There are several ways to turn ordinary steel plates into high-standard forging materials in China:

Cold Forging

Cold Forging is an industrial process of working metals with dies, hammers and punches that have no heat source.

This process does not deform the metal by heating it. It uses pressure to deform the metal in a cold state.

Cold Forging can be used to produce parts of a wide range of sizes and shapes. Parts are manufactured by forming the metal under pressure in a die or die block.

Cold Forging can also be used to form complex shapes by upsetting or bending the material over an appropriately shaped die block.

The primary benefits of cold forging are its ability to produce close tolerances and a smooth surface finish, as well as the use of less expensive materials that can be hardened through workmanship alone.

Cold forging processes include pressing, extruding, and rolling.

Hot Forging

Hot forging is an important process in steel production. During the process, hot metal is shaped into a desired shape and size by force, pressure, and impact.

The temperature of the steel should be above its recrystallization temperature, but below its melting point to ensure that it does not melt during the process.

Hot forging can be used to create a wide range of products, including bearings, axles, gears, fasteners, and other mechanical parts.

Mechanical Pressure Forging

Mechanical Pressure Forging is a process that uses mechanical force to deform the metal, which results in excellent plasticity and toughness.

The mechanical pressure forging process requires less time than the traditional forging process. It can reduce the deformation of steel during forging, and improve the standard of forged products.

Mechanical pressure forging is mainly used for manufacturing large-diameter and small-diameter shafts, such as gear shafts, gearboxes, and pulley wheels.

Mechanical pressure forging is an advanced technology with high efficiency, low cost, and high-standard.