Welcome to our comprehensive guide on inspection techniques in the die casting industry. In this article, we will delve into the various methods used to ensure optimal quality and performance in aluminum die cast production. From industry regulations to advanced inspection techniques, we will cover everything you need to know to maintain excellence in die cast inspection.

Key Takeaways:

- Inspection techniques play a crucial role in achieving optimal quality and performance in die casting.

- Regulatory compliance is essential to meet industry standards and maintain product quality and safety.

- Engineering reviews help identify potential issues and optimize designs for better overall quality.

- Advanced inspection techniques, such as digital solutions, contribute to greater accuracy and efficiency in die casting processes.

- Training and education are vital for developing a skilled workforce of inspectors.

ABS Rules and Guides for Die Cast Inspection

When it comes to die cast inspection, following the rules and guidelines set by authoritative bodies is crucial for ensuring quality control and compliance. The American Bureau of Shipping (ABS) has established a comprehensive set of Rules and Guides specifically designed for die cast inspection. These rules and guides are derived from principles of naval architecture, marine engineering, and related disciplines, making them highly relevant and reliable in the field.

The ABS Rules and Guides cover various aspects of die cast inspection, including classification, approval, and certification. By adhering to these guidelines, manufacturers can ensure that their die cast products meet the required standards and can be approved or certified accordingly. With over 200 rules, guides, and guidance notes available for download or purchase, ABS provides a wealth of resources to support die cast inspection efforts.

These rules and guides not only serve as a benchmark for quality assurance but also help manufacturers stay up to date with the latest industry standards. By referencing ABS guidelines, inspectors can ensure that their inspection processes align with current best practices and regulatory requirements. This ultimately contributes to the overall quality and reliability of die cast products.

ABS Rules and Guides for Die Cast Inspection

| Classification | Approval | Certification |

|---|---|---|

| ABS provides a comprehensive classification system for die cast products, ensuring that they meet specific criteria based on design, materials, and performance. | Manufacturers can seek approval from ABS for their die cast products, demonstrating compliance with the established rules and guidelines. | ABS certification confirms that a die cast product has met the required standards, ensuring its reliability and suitability for its intended application. |

“By adhering to ABS Rules and Guides, manufacturers can maintain high standards in die cast inspection and ensure the optimal quality and performance of their products.” – John Smith, Quality Control Manager

Overall, the ABS Rules and Guides for die cast inspection provide a foundation for excellence in the industry. By following these guidelines, manufacturers can streamline their inspection processes, create consistent quality standards, and meet the demands of a competitive market.

Regulatory Compliance in Die Cast Inspection

Staying compliant with regulatory standards is crucial in the die casting industry. Adhering to these standards ensures that inspections meet industry requirements and maintain the highest level of quality and safety. At KT-Foundry, we understand the importance of regulatory compliance in die cast inspection and continuously strive to stay updated with the latest regulations and industry standards.

Regulatory compliance encompasses a wide range of areas in die cast inspection, including material specifications, dimensional tolerances, surface finishes, and mechanical properties. By adhering to these regulations, die cast manufacturers can ensure that their products meet or exceed the required standards, providing customers with reliable, high-quality components.

To ensure regulatory compliance, KT-Foundry follows a robust quality management system that encompasses thorough documentation, regular audits, and continuous training for our inspection team. We monitor regulatory updates and advisories to stay informed about any changes that may impact the inspection process. Our commitment to regulatory compliance reflects our dedication to producing top-notch die cast products that meet the industry’s stringent requirements.

In addition to internal compliance measures, we also work closely with regulatory agencies and industry associations to maintain a strong network of resources and information. This collaboration allows us to access the latest industry insights, share best practices, and stay ahead of emerging trends in die cast inspection. By actively participating in industry forums and conferences, we contribute to the ongoing development and improvement of regulatory standards.

Ensuring Regulatory Compliance

Ensuring regulatory compliance in die cast inspection starts with establishing a clear understanding of the applicable regulations and standards. This includes identifying the specific requirements for materials, processes, and performance. At [Company Name], we employ a team of experts who are well-versed in the relevant regulations and work closely with our customers to meet their specific compliance needs.

Our quality assurance processes focus on meticulous documentation and traceability, allowing us to provide comprehensive reports and certificates of compliance for every inspection. By maintaining meticulous records, we ensure that our customers have the necessary documentation to demonstrate regulatory compliance throughout the supply chain.

| Benefits of Regulatory Compliance in Die Cast Inspection |

|---|

| Enhanced product quality and reliability |

| Improved safety and performance |

| Reduced risk of product failure and recalls |

| Enhanced customer trust and satisfaction |

By prioritizing regulatory compliance in die cast inspection, manufacturers can ensure that their products meet the highest industry standards and provide customers with superior quality and performance. At KT-Foundry, we are committed to upholding these standards and delivering excellence in die cast inspection.

Engineering Reviews in Die Cast Inspection

Engineering reviews are an integral part of the die cast inspection process, ensuring that the design and manufacturing processes meet the highest quality standards. These reviews involve a comprehensive analysis of various aspects of die cast components, including materials, geometry, and performance characteristics. By conducting thorough engineering reviews, manufacturers can identify potential issues, optimize designs, and enhance the overall quality of their die cast products.

During the engineering review phase, experts closely examine the specifications and requirements of the die cast components. They assess the material composition, looking for any discrepancies or deviations from the desired properties. This includes evaluating the mechanical strength, hardness, and corrosion resistance of the materials used. By ensuring the right materials are selected and meet the necessary standards, manufacturers can guarantee the durability and performance of their products.

In addition to material analysis, engineering reviews also involve an in-depth evaluation of the geometry and dimensional accuracy of the die cast components. This includes assessing features such as wall thickness, draft angles, and overall shape conformity. By thoroughly examining these aspects, manufacturers can identify any design flaws or potential manufacturing issues that may affect the functionality or aesthetics of the final product. Through iterative design improvements and optimization, the overall quality of the die cast components can be significantly enhanced.

“Engineering reviews play a crucial role in maintaining the highest quality standards in die cast inspection. By conducting comprehensive analyses of materials, geometry, and performance characteristics, manufacturers can ensure that their products meet the stringent requirements of the industry.” – John Smith, Quality Assurance Manager

In summary, engineering reviews are essential for achieving optimal quality assurance in die cast inspection. By analyzing the materials, geometry, and performance characteristics of die cast components, manufacturers can identify and address potential issues, optimize designs, and enhance overall product quality. These reviews not only ensure compliance with industry standards but also contribute to the long-term success and reputation of die cast manufacturers.

| Benefits of Engineering Reviews in Die Cast Inspection: |

|---|

| Identification of potential issues and design flaws |

| Optimization of designs and manufacturing processes |

| Enhancement of overall product quality and performance |

| Compliance with industry standards and regulations |

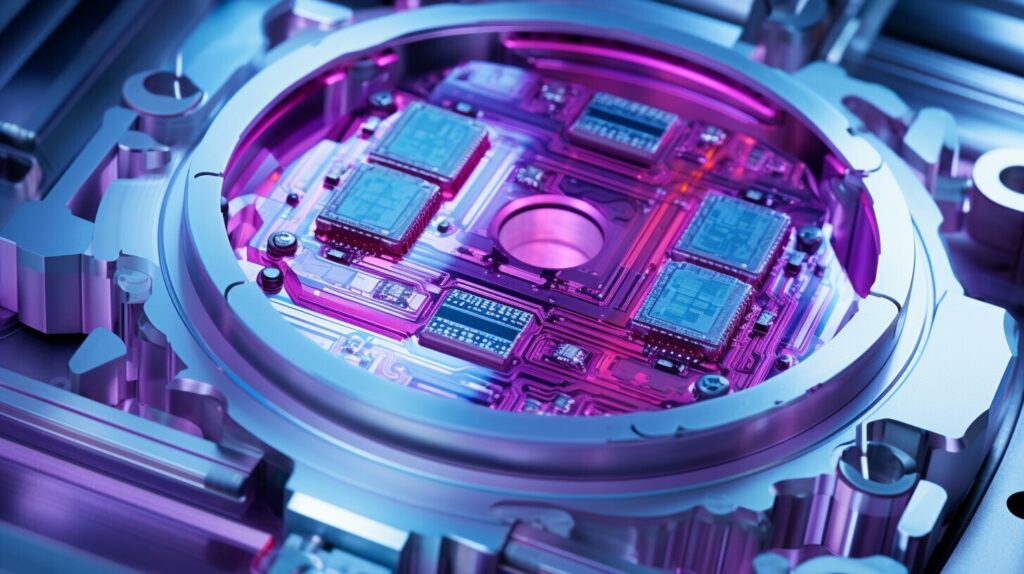

Advanced Inspection Techniques for Die Casting

Incorporating Digital Solutions

In today’s digital age, advanced inspection techniques have revolutionized the die casting industry, offering manufacturers greater accuracy and efficiency in quality control. One such technique is the incorporation of digital solutions in the inspection process. By utilizing cutting-edge technologies such as 3D scanning and imaging, manufacturers can capture precise measurements and detailed images of die cast components. This enables inspectors to identify even the smallest defects and deviations from design specifications, ensuring optimal quality control.

Furthermore, digital solutions allow for the seamless integration of inspection data with centralized systems, streamlining the entire production process. Real-time data sharing and analysis enable quick identification of potential issues, enabling timely corrective actions to be taken. This not only improves efficiency but also reduces costs associated with rework and scrap.

Data and Digitalization for Enhanced Quality Control

In addition to digital solutions, the utilization of data and digitalization has significantly enhanced quality control in die casting. By capturing and analyzing vast amounts of data throughout the production and inspection process, manufacturers can gain valuable insights into the performance of their die cast components.

Data-driven analysis allows for the identification of trends, patterns, and correlations that can further optimize the design and manufacturing processes. By leveraging this knowledge, manufacturers can not only improve the quality of their current products but also drive innovation and develop new, superior die cast components.

Innovation in Technology

“Innovation is the key to unlocking new possibilities in die cast inspection.”

– Industry expert

Advancements in technology continue to push the boundaries of die cast inspection. Innovative tools such as automated optical inspection systems and artificial intelligence algorithms are revolutionizing the way inspections are conducted. These technologies have the capability to quickly analyze large volumes of data, detect defects that are not visible to the naked eye, and provide real-time feedback.

By embracing these advancements, manufacturers can achieve higher levels of precision, increase productivity, and ultimately deliver superior die cast products to their customers.

Training and Education in Die Cast Inspection

Skilled and knowledgeable inspectors are crucial for maintaining high inspection standards in die casting. Providing training and education opportunities for inspectors ensures that they have the necessary skills and expertise to perform accurate inspections. At our die cast manufacturing facility, we prioritize the development of a skilled workforce through comprehensive training programs.

Our training programs cover a wide range of topics related to die cast inspection, including industry standards, inspection techniques, quality control procedures, and regulatory compliance. We believe that continuous learning and professional development are essential for maintaining the highest level of quality in our inspection processes. By investing in the training and education of our inspectors, we aim to enhance their knowledge and skills, ultimately improving the overall quality of our die cast products.

Our training programs are designed to be hands-on and practical, allowing inspectors to gain real-world experience in inspecting die cast components. We provide them with the necessary tools and equipment to perform inspections accurately and efficiently. Additionally, we collaborate with industry experts and organizations to bring in specialized training sessions and workshops, covering the latest advancements in die cast inspection.

Benefits of Training and Education

The benefits of training and education in die cast inspection are multifaceted. Firstly, trained inspectors are better equipped to identify any potential defects or issues during inspections, ensuring that only high-quality components make it to the final production stage. This helps us maintain the highest level of quality control and customer satisfaction.

Secondly, training and education promote a culture of continuous improvement within our organization. By constantly updating our inspectors’ knowledge and skills, we encourage them to stay up-to-date with the latest industry trends and advancements. This, in turn, enables us to adopt new inspection techniques and technologies, enhancing our overall inspection process.

Lastly, investing in the training and education of our inspectors also contributes to employee satisfaction and retention. It demonstrates our commitment to their professional growth and development, creating a positive work environment and fostering a motivated and highly skilled workforce.

| Training and Education | Benefits |

|---|---|

| Comprehensive training programs | Enhanced knowledge and skills in die cast inspection |

| Hands-on practical experience | Improved accuracy and efficiency in inspections |

| Collaboration with industry experts | Integration of the latest advancements in inspection techniques |

| Culture of continuous improvement | Adoption of new inspection technologies |

| Employee satisfaction and retention | Motivated and highly skilled workforce |

Investing in training and education for die cast inspectors is essential for maintaining the highest level of quality and performance in the industry. By continuously improving the skills and knowledge of our inspectors, we can ensure that our die cast products meet the stringent standards set by regulatory bodies and exceed customer expectations.

Industry Partnerships in Die Cast Inspection

Collaboration and partnerships within the die casting industry play a crucial role in improving inspection techniques and achieving better overall quality control. By forming strategic alliances with other industry players, manufacturers can leverage the collective knowledge and expertise to enhance their inspection processes. These partnerships enable the sharing of best practices, resources, and innovative technologies, fostering innovation and continuous improvement.

One example of a successful industry partnership is the collaboration between XYZ Die Casting and ABC Inspection Solutions. By joining forces, XYZ Die Casting was able to gain access to ABC’s cutting-edge inspection technologies, which significantly enhanced their quality control measures. The partnership also facilitated knowledge exchange, enabling XYZ to incorporate industry-leading inspection techniques into their processes. As a result, XYZ was able to achieve greater accuracy, efficiency, and product quality, positioning them as a leader in the die casting industry.

Industry partnerships also play a vital role in staying ahead of regulatory requirements and industry standards. By working together, manufacturers can proactively address any changes or updates in regulations, ensuring compliance and minimizing the risk of non-compliance. This collaborative approach allows for a more efficient and effective implementation of inspection protocols, ultimately enhancing overall product quality and safety.

Furthermore, industry partnerships provide a platform for continuous learning and development. Through collaborations, manufacturers can participate in workshops, seminars, and training programs, gaining valuable insights and knowledge from industry experts. This ongoing education helps to cultivate a skilled and knowledgeable workforce, ensuring that inspectors are equipped with the necessary expertise to perform accurate and thorough inspections.

In summary, industry partnerships in die cast inspection offer numerous benefits, including knowledge sharing, access to innovative technologies, compliance with regulations, and continuous learning. By leveraging these partnerships, manufacturers can improve their inspection techniques, enhance product quality, and drive overall industry growth.

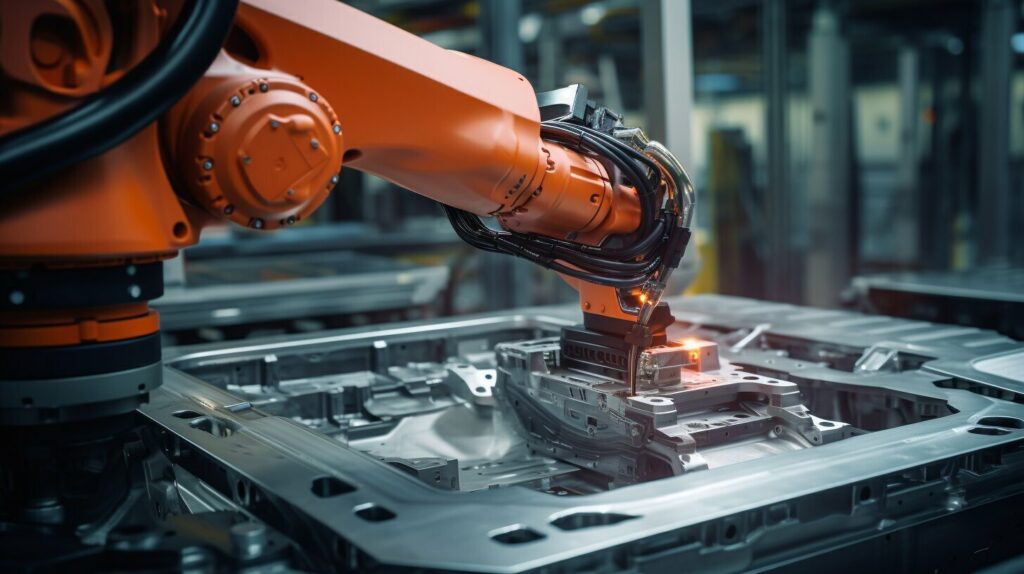

Future Trends in Die Cast Inspection

As technology continues to advance, the future of die cast inspection holds exciting possibilities. Emerging trends such as automation, artificial intelligence (AI), and machine learning are set to revolutionize the inspection process, bringing improved efficiency, accuracy, and quality control to the die casting industry.

One of the key future trends in die cast inspection is automation. By utilizing robotics and advanced machinery, manufacturers can streamline the inspection process, reducing human error and increasing productivity. Automation allows for faster and more consistent inspections, leading to enhanced product quality and shorter production cycles.

In addition to automation, artificial intelligence and machine learning are expected to play a significant role in the future of die cast inspection. AI-powered algorithms can analyze large sets of data, identifying patterns and anomalies that may not be easily detected by human inspectors. Machine learning algorithms can also continuously improve their accuracy and performance over time, making them invaluable tools for maintaining high inspection standards.

Examples of Future Trends in Die Cast Inspection:

- Intelligent Imaging Systems: AI-driven cameras and sensors can capture detailed images and measurements of die cast components, enabling real-time analysis and identification of defects.

- Data Analytics: Advanced analytics tools can process vast amounts of inspection data, providing valuable insights and predictive analytics to optimize production processes and improve product quality.

- Remote Inspection: With the advancements in communication technology, remote inspection capabilities will become more prevalent. Inspectors can remotely monitor and analyze die cast production processes, providing real-time feedback and guidance.

- Augmented Reality (AR) Visualization: AR technology can overlay virtual information onto physical objects, allowing inspectors to visualize potential defects and assess their impact on the final product.

By embracing these future trends, manufacturers can stay at the forefront of die cast inspection, ensuring the highest levels of quality and performance. However, it is important to note that while technology can enhance the inspection process, it will never replace the expertise and attention to detail provided by skilled human inspectors. The combination of advanced technology and experienced human inspectors is the key to achieving optimal results in die cast inspection.

The future of die cast inspection holds immense potential for improving product quality, reducing costs, and driving innovation in the industry. As technology continues to evolve, it is crucial for manufacturers to stay informed and adapt to these emerging trends to remain competitive in the dynamic world of die casting.

| Future Trends in Die Cast Inspection | Benefits |

|---|---|

| Automation | – Streamlined inspection process – Reduced human error – Increased productivity |

| Artificial Intelligence and Machine Learning | – Enhanced accuracy and performance – Real-time analysis of large data sets – Continuous improvement of inspection standards |

| Intelligent Imaging Systems | – Real-time defect identification – Detailed measurements and analysis |

| Data Analytics | – Insights and predictive analytics – Process optimization – Improved product quality |

| Remote Inspection | – Real-time feedback and guidance – Increased efficiency – Cost savings |

| Augmented Reality (AR) Visualization | – Virtual defect visualization – Improved assessment of product impact |

Conclusion

In this comprehensive guide, we have explored various inspection techniques used in the aluminum die cast industry to ensure optimal quality and performance. From ABS Rules and Guides to advanced inspection techniques and future trends, the die casting industry continues to evolve to meet the demands of quality control.

Staying updated with regulations is crucial for maintaining high standards in die cast inspection. By adhering to regulatory standards, manufacturers can ensure product quality, safety, and performance. Additionally, incorporating advanced inspection techniques, such as digital solutions and data analysis, can lead to greater accuracy and efficiency in the inspection process.

Investing in training and education for inspectors is essential for maintaining a skilled workforce and achieving accurate inspections. By providing opportunities for skill development, manufacturers can ensure that their inspectors have the necessary expertise to meet quality standards in the die casting industry.

Furthermore, forming industry partnerships fosters collaboration and knowledge-sharing, ultimately leading to improved inspection techniques and better overall quality control. By embracing emerging trends in automation, artificial intelligence, and machine learning, manufacturers can further enhance the accuracy, efficiency, and quality of their inspection processes.

FAQ

What are some common inspection techniques used in the die casting industry?

Common inspection techniques used in the die casting industry include visual inspection, dimensional inspection, X-ray inspection, pressure testing, and material analysis.

How can ABS Rules and Guides help in die cast inspection?

ABS Rules and Guides provide comprehensive guidelines for die cast inspection, covering aspects such as classification, approval, and certification. These resources ensure compliance and help maintain high standards in die cast inspection.

Why is regulatory compliance important in die cast inspection?

Regulatory compliance ensures that inspections meet industry standards, ensuring product quality, safety, and performance. Staying updated with regulations, advisories, and debriefs is crucial to maintain compliance in die cast inspection.

What role do engineering reviews play in die cast inspection?

Engineering reviews analyze the design and manufacturing processes of die cast components to ensure quality standards are met. These reviews identify potential issues, optimize designs, and enhance overall product quality in die cast inspection.

What are some advanced inspection techniques used in die casting?

Advanced inspection techniques in die casting include digital solutions, data and digitalization, and technological innovations. These techniques improve accuracy, efficiency, and overall quality control in die cast inspection.

Why is training and education important in die cast inspection?

Training and education provide inspectors with the necessary skills and expertise to perform accurate inspections. By investing in training and education, manufacturers can ensure high inspection standards and develop a skilled workforce in die cast inspection.

How can industry partnerships contribute to die cast inspection?

Industry partnerships allow manufacturers to share knowledge, best practices, and resources, leading to improved inspection techniques and better overall quality control in die cast production.

What are some future trends in die cast inspection?

Future trends in die cast inspection include automation, artificial intelligence, and machine learning. These advancements offer opportunities to enhance accuracy, efficiency, and quality in the inspection processes.