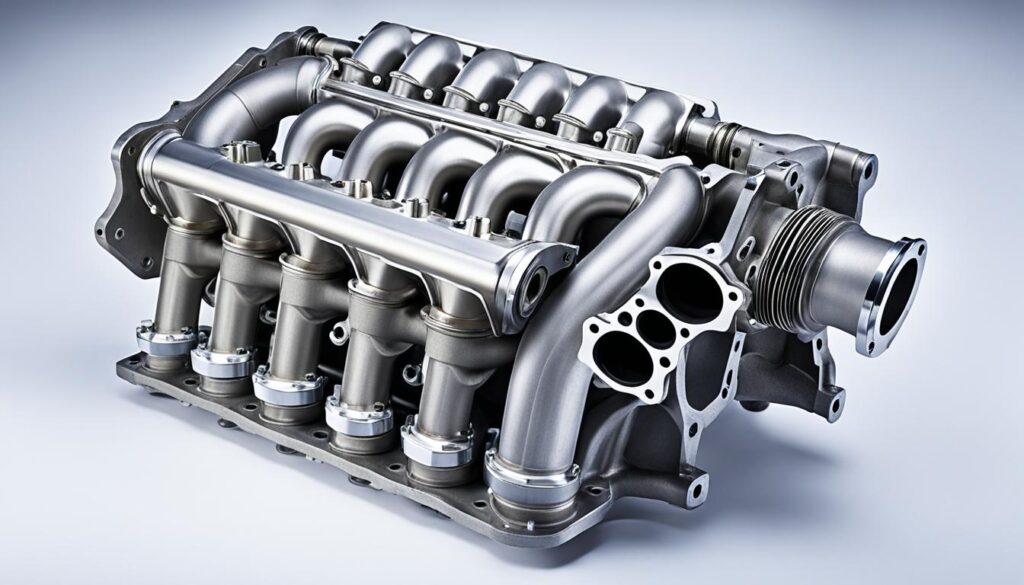

As automotive engineers, we know how vital the exhaust manifold is for engine performance and controlling emissions. It collects and directs the hot gases from the engine cylinders to the exhaust system. For the best performance and life, the exhaust manifold must be made with great care and precision.

At KT-Foundry, we’ve been making top-notch exhaust manifolds for years. Our skill in using cast iron and stainless steel lets us create parts that can handle the engine’s high temperatures and tough conditions.

Today’s exhaust manifolds need to ensure good gas flow and stand up to heat, oxidation, and thermal fatigue. With better engine performance, stainless steel alloys are more popular. They offer smooth inner walls, quick heat transfer, and are lighter than cast iron.

Key Takeaways

- Exhaust manifolds are key parts that must handle extreme temperatures and tough conditions.

- Cast iron was once common, but stainless steel is now preferred for its better performance.

- KT-Foundry excels in making high-quality exhaust manifolds with advanced casting methods.

- Stainless steel manifolds have smooth inner walls, fast heat transfer, and are lighter.

- Quality and attention in making exhaust manifolds are crucial for their long-term reliability and performance.

Importance of Exhaust Manifolds in Automotive Engineering

The exhaust manifold is key in automotive engineering. It collects and directs exhaust gas from the engine. Its design is vital for better engine power, fuel use, and meeting emissions standards.

When making exhaust manifolds, engineers must think about engine layout, thermal fatigue, oxidation resistance, and high-temperature strength.

Exhaust Gas Management

The main job of the exhaust manifold is to manage exhaust gases from the engine. It needs to be designed to reduce resistance and avoid cylinder interference. This helps keep engine power up, fuel use down, and emissions in check.

Material Requirements

Choosing the right material for exhaust manifolds is crucial. They must handle high temperatures and thermal changes during engine use. Cast iron and stainless steel are top choices.

Stainless steel is preferred for its durability, resistance to corrosion, and flexibility in design. It’s a top pick for modern cars.

The material must stand up to thermal fatigue and oxidation to last long and perform well. It also needs to be strong at high temperatures, facing extreme heat and stress during engine use.

“The exhaust manifold is the unsung hero of the engine, responsible for efficiently managing the high-temperature, high-pressure exhaust gases that power the vehicle forward.”

Advancements in Exhaust Manifold Casting

The stainless steel investment casting process is now a top choice for making exhaust manifolds. It beats traditional sand casting in many ways. This method lets us create complex shapes with thin walls. This boosts engine performance and efficiency.

Stainless Steel Alloys for Exhaust Manifold Casting

Two main types of stainless steel are used for casting exhaust manifolds: austenitic and ferritic. Austenitic stainless steel, like 304 and 316, is great for high heat because it’s strong. Ferritic stainless steel, such as 409 and 439, is better at fighting oxidation and handling heat because it doesn’t expand much when heated.

This casting process also gives a smooth surface. This means less exhaust resistance and better airflow. The smooth surface and stainless steel’s properties make exhaust manifolds work well and last long.

At KT-Foundry, we’re experts in making top-notch cast stainless steel exhaust manifolds. Our focus on innovation and detail has made us a reliable partner in the automotive world.

Conclusion

At KT-Foundry, we’re proud of our exhaust manifold casting expertise. We lead in making high-performance car parts. Our cast stainless steel exhaust manifolds are made with advanced techniques. These manifolds use stainless steel’s great high-temperature strength, oxidation resistance, and design flexibility. This makes them better for engine performance, emissions control, and fuel efficiency.

The car industry is always changing, and KT-Foundry stays ahead in exhaust manifold casting innovation. We’re committed to giving our customers reliable and green solutions. We aim to go beyond what’s expected in automotive manufacturing.

We’re excited for the future and our ongoing innovation and growth. We’ll keep delivering top-notch stainless steel castings that help vehicles perform better. With our focus on quality, KT-Foundry will keep being a key partner in the automotive components industry.

FAQ

What is the importance of the exhaust manifold in automotive engineering?

The exhaust manifold is key to the exhaust system, right after the engine. It must handle high temperatures up to 900°C and resist oxidation well. It also needs to be strong at high temperatures and not crack from heat changes.

Its job is to collect and direct exhaust gas from the engine. This helps keep the engine’s power up. It also makes sure exhaust gases don’t mix too much between cylinders.

What materials are commonly used for exhaust manifold casting?

Before, ductile iron was often used. But as engines got better, cast stainless steel became more popular. Stainless steel is lighter and transfers heat faster than cast iron.

What are the benefits of using the investment casting process for exhaust manifold production?

Investment casting is now a top choice for making exhaust manifolds. It’s better than sand casting in many ways. This method makes complex shapes with thin walls, which helps engines run better.

It also makes the surface smooth, which lowers exhaust resistance. This means the engine uses less fuel and produces fewer emissions.

What types of stainless steel are used for exhaust manifold casting?

Two main types of stainless steel are used: austenitic and ferritic. Austenitic stainless steel is great for high temperatures. Ferritic stainless steel is better at fighting oxidation and has less thermal expansion.

How does KT-Foundry’s expertise in exhaust manifold casting contribute to the automotive industry?

KT-Foundry is a leader in making high-quality cast stainless steel exhaust manifolds. They use advanced investment casting. This lets them make manifolds that are strong at high temperatures and resist oxidation well.

KT-Foundry’s manifolds improve engine performance, reduce emissions, and make cars more fuel-efficient. They use stainless steel alloys for their many benefits.