Welcome to our guide on cast iron counterweights, an essential component for ensuring stability, balance, and safety in various industries and applications. Cast iron counterweights are known for their durability, strength, and reliability, making them the go-to choice for many mechanical systems and equipment.

Whether you are in construction, agriculture, or manufacturing, cast iron counterweights can help maximize efficiency, reduce vibrations, and optimize performance. With the right weight capacity, dimensions, and material quality, you can greatly enhance the effectiveness of your projects.

However, not all cast iron counterweights are created equal. Quality is crucial to ensure the safety and longevity of your equipment and operations. In this guide, we will explore the many benefits and applications of cast iron counterweights, as well as provide tips on finding the right solution for your needs.

Let’s dive deeper into the world of cast iron counterweights and discover how they can help take your projects to the next level.

Understanding Cast Iron Counterweight Applications

A brief introduction to the use of cast iron counterweight iron applications, such as elevators, forklifts, forklifts, cranes, machinery, fitness equipment, and other possible applications.

Elevators are one of the most common applications for cast iron counterweights. The counterweight helps to balance the elevator car and keep it level as it moves up and down. The counterweight also helps to absorb some of the shock when the elevator car comes to a stop.

Forklifts and other material handling equipment often use cast iron counterweights to help balance the load that they are carrying. The counterweights help to prevent the equipment from tipping over when it is carrying a heavy load.

Cranes and other lifting equipment use counterweights to help balance the load that they are lifting. The counterweights help to prevent the equipment from tipping over when it is lifting a heavy load.

Machinery often uses cast iron counterweights to help balance the load that it is carrying. The counterweights help to prevent the machinery from tipping over when it is carrying a heavy load.

Fitness equipment often uses cast iron counterweights to help balance the load that it is carrying. The counterweights help to prevent the equipment from tipping over when it is carrying a heavy load.

There are many other potential applications for cast iron counterweights. They can be used in a variety of applications where it is necessary to help balance a load.

Understanding Cast Iron Counterweight Applications in Agricultural Machinery

Cast iron counterweights are essential in agricultural equipment, particularly in tractors, and can provide many benefits. Tractor weight front is essential to ensuring the vehicle’s stability and safety while operating. It is not uncommon for the loads to be carried in the rear of tractors to cause bent or broken axles, causing the tractor to become unstable. Counterweights on the front of the tractor help prevent this.

Placing the counterweights on the front of the tractor also helps improve traction, especially when driving on muddy terrain. The added weight helps grip the ground, minimizing slippage and making the tractor easier to maneuver.

Overall, cast iron counterweights play an essential role in various applications, providing stability, balance, and safety to all mechanical systems.

Enhancing Efficiency with Cast Iron Counterweights

Cast iron counterweights are essential components in various mechanical systems and equipment. The strategic placement of these counterweights contributes significantly to the reduction of vibrations, optimization of performance, and increase of precision in machinery. Indeed, the incorporation of cast iron counterweights into your project can result in significant gains in efficiency and productivity.

One primary advantage of cast iron counterweights is their ability to reduce the vibrations caused by mechanical systems and equipment. Vibrations can lead to decreased precision and efficiency and even damage to the machinery. With cast iron counterweights, however, the vibrations can be dampened, resulting in smoother and more stable operation. This is especially important in high-speed machinery or in equipment that requires precise movements, such as robotic systems.

Another way cast iron counterweights enhance efficiency is through optimizing performance. By acting as a balancing mechanism, cast iron counterweights can increase the accuracy and precision of machinery, leading to better overall performance. In some cases, counterweights may be necessary to ensure that machinery can perform its intended function at all.

Finally, using cast iron counterweights can help increase productivity by reducing the amount of time that machinery and equipment need to be stopped for maintenance. By reducing vibrations and optimizing performance, the machinery can work more efficiently and effectively, resulting in less wear and tear. This means that equipment will require less frequent maintenance, leading to more available uptime for production.

“The strategic placement of these counterweights contributes significantly to the reduction of vibrations, optimization of performance, and increase of precision in machinery.”

Overall, the use of cast iron counterweights can have a significant impact on the efficiency and productivity of various industries and applications. By reducing vibrations, optimizing performance, and increasing productivity, these counterweights provide stability and balance that are essential for the smooth operation of mechanical systems and equipment.

Ensuring Safety with Cast Iron Counterweights

When it comes to agricultural operations, safety should always be a top priority. This is where cast iron counterweights come in handy, particularly tractor weight front counterweights. These counterweights are specially designed to provide stability and balance to tractors during various tasks, such as plowing, tilling, and harvesting.

By adding a cast iron counterweight to the front of a tractor, the weight distribution of the vehicle is significantly improved. This helps minimize the risk of the tractor tipping over, especially when working on steep or uneven terrain. It also ensures that the tractor can handle heavy loads without experiencing stability issues.

Furthermore, cast iron counterweights are resistant to the wear and tear that comes with daily use, whether it be from exposure to harsh weather conditions or impact from debris. Investing in high-quality cast iron counterweights can help prevent accidents and injuries, and ultimately save time and money in the long run.

Finding the Right Cast Iron Counterweight for Your Needs

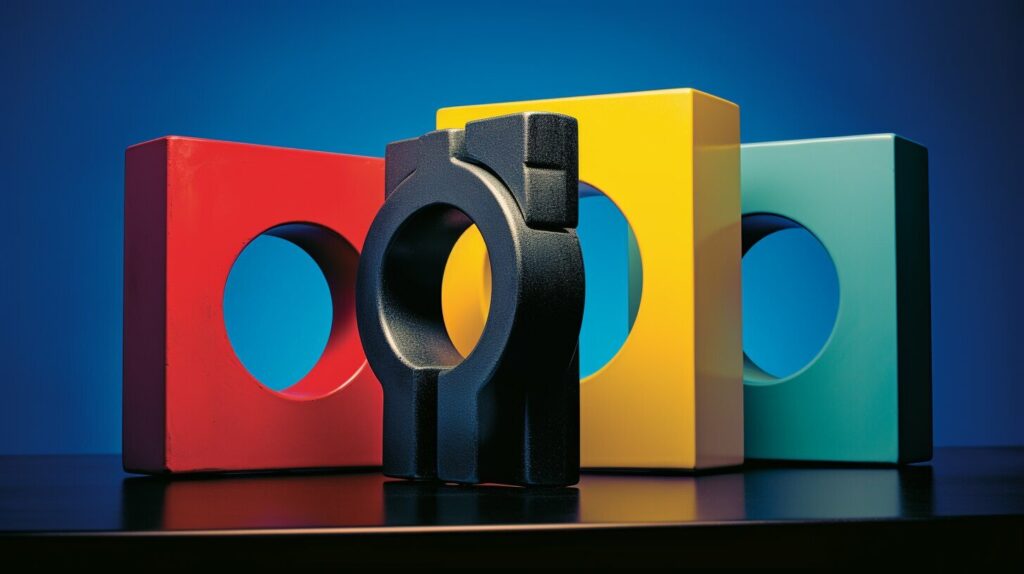

Choosing the right cast iron counterweight is a crucial step in ensuring the optimal performance and safety of your machinery or equipment. Here are some factors to consider when selecting a cast iron counterweight:

- Weight Capacity: Make sure to choose a counterweight that can handle the weight of your equipment. Overloading the counterweight can cause instability and compromise the safety of your operations.

- Dimensions: Consider the size of your equipment and the available space for the counterweight. The dimensions of the counterweight should be compatible with your machinery and allow for proper placement.

- Material Quality: Quality is key when choosing a cast iron counterweight. Low-quality materials or poorly manufactured counterweights can lead to premature wear and tear, compromising the efficiency and safety of your equipment.

At Cast Iron Counterweights for Sale, we offer high-quality cast iron counterweights that meet the industry standards and exceed our customers’ expectations. Our products are designed to provide durability and reliability, ensuring optimal performance and safety of your machinery or equipment.

Please briefly introduce a good example of KT foundry in manufacturing cast iron counterweights.

KT Iron Works manufactures a wide variety of cast iron counterweights, including those for tractors, construction equipment, and other machinery. The company also offers a wide range of custom casting services, including the ability to create custom counterweights to meet the specific needs of its customers.

If you are in need of cast iron counterweights, KT Iron Works is the company you can trust to provide you with the quality products and services you need. For more information about the products and services offered by KT Iron Works, please visit their website .

With our extensive experience in the industry and commitment to quality, you can trust us to provide the best cast iron counterweight solutions for your business. Contact us today for expert advice and to learn more about our product offerings.

Cast iron counterweight VS concrete counterweight

Concrete counterweight blocks are the most common type of counterweight used in construction. They are made from a mixture of aggregate, Portland cement and water. Concrete counterweights are typically cast in block form and used to offset the weight of objects such as elevators, cranes, punching presses and large air conditioning units.

Cast iron counterweights are made from pig iron, which is a type of iron that contains a high percentage of carbon. Cast iron counterweights are usually cast in a foundry and then machined to the desired shape. They are used in a variety of applications including material handling, automotive and construction.

Cast iron counterweight advantages:

1. Cast iron counterweights are stronger and more durable than concrete counterweights.

2. Cast iron counterweights can be machined to any desired shape.

3. Cast iron counterweights are less likely to crumble or crack over time.

4. Cast iron counterweights have a higher resistance to wear and tear.

5. Cast iron counterweights are recyclable.

6. Cast iron counterweights are not susceptible to freeze-thaw cycles.

7. Cast iron counterweights are not affected by chemicals or other environmental factors.

8. Cast iron counterweights can be painted or coated for additional protection.

9. Cast iron counterweights are available in a variety of sizes and weights.

10. Cast iron counterweights are more expensive than concrete counterweights.

Investing in quality cast iron counterweights may require a slightly higher upfront cost, but the benefits are well worth it. You’ll have a durable, safe, and efficient solution that will serve you well for years to come. Don’t compromise on quality when it comes to cast iron counterweights – choose wisely to ensure optimal results.

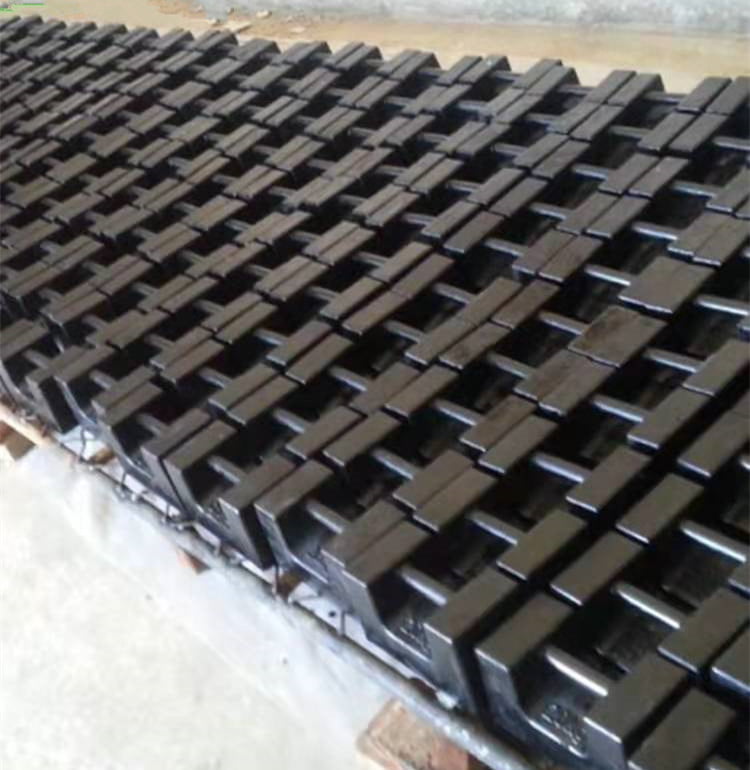

How Cast Iron Counterweights Are Made

Cast iron counterweights are crafted with precision and care using a specific recipe of materials and techniques. The process begins with the selection of high-quality iron, which is melted down in a furnace and poured into molds to create the desired shape and weight.

The molds are carefully designed to ensure accuracy and consistency in the final product. Once the iron has cooled and solidified, the counterweights are removed from the molds and subjected to finishing processes, including grinding and polishing, to achieve the desired smoothness and surface texture.

Quality control is a crucial part of the manufacturing process for cast iron counterweights. Each finished product is inspected and tested to ensure that it meets the required weight, dimensions, and material quality standards. Any defects or imperfections are identified and corrected before the product is released to the market.

The Iron Counterweight Recipe

The recipe for creating high-quality cast iron counterweights involves a precise combination of iron, carbon, and other elements. The specific recipe may vary depending on the intended use and weight capacity of the counterweight. However, the general recipe involves melting down iron and adding carbon to create a mixture that is poured into molds and cooled to form the final product.

In addition to the recipe, the molding process also plays a crucial role in creating durable and reliable cast iron counterweights. The molds must be designed to withstand the high heat and pressure involved in the casting process and must be precise in their dimensions to ensure consistency in the finished product.

With their strength, durability, and precision engineering, cast iron counterweights are an essential component in many industries and applications. From enhancing efficiency in mechanical systems to ensuring safety in agricultural equipment, quality cast iron counterweights offer a robust and reliable solution that can withstand extreme conditions and provide long-term stability and balance.

Integrating Cast Iron Counterweights Into Your Project

Properly integrating cast iron counterweights into your project can greatly enhance its efficiency and safety. Here are some tips to help you get started:

Determine the Right Weight and Placement

Before purchasing a cast iron counterweight, it’s important to determine the weight and placement required for your project. This will depend on various factors such as the size and weight of the machinery or equipment, as well as the specific application. Consulting with a professional can help ensure that you choose the right counterweight for your needs.

Consider Customization Options

Depending on your project requirements, you may need a customized cast iron counterweight. Many manufacturers offer customization options to meet specific weight, size, and design requirements. Consulting with a manufacturer can help you determine if this is necessary for your project and what options are available.

Follow Proper Installation Procedures

Proper installation is crucial for ensuring the effectiveness and safety of cast iron counterweights. Follow all manufacturer guidelines and recommendations for installation, including the use of appropriate tools and equipment. Additionally, consider hiring a professional installer to ensure that the counterweight is installed correctly.

Examples of Successful Implementations

There are many successful implementations of cast iron counterweights across various industries and applications. For example, in the construction industry, counterweights are often used to stabilize cranes and other heavy equipment. In the automotive industry, counterweights can be used to balance rotating parts such as engines and wheels. Consulting with experts in these industries can provide useful insights into how to successfully integrate counterweights into your project.

By following these tips and utilizing quality cast iron counterweights, you can optimize the efficiency and safety of your project. Make sure to consult with professionals and choose a trusted manufacturer to ensure the best results.

Frequently Asked Questions About Cast Iron Counterweights

Are you considering using cast iron counterweights for your project? Here are some frequently asked questions about cast iron counterweights to help guide you in your decision-making process.

What are cast iron counterweights?

Cast iron counterweights are heavy objects made of cast iron used to provide stability, balance, and weight to various mechanical systems and equipment.

What are the benefits of using cast iron counterweights?

Cast iron counterweights offer several benefits, including:

- Improving efficiency and performance of machines and equipment

- Reducing vibrations and oscillations

- Enhancing safety in various industries

- Providing stability and balance to heavy equipment and machinery

- Offering a durable and reliable solution

What applications are cast iron counterweights suitable for?

Cast iron counterweights are used in various industries and applications, including:

- Agriculture

- Construction

- Mining

- Aerospace

- Marine

- And more

They are particularly suitable for applications where high weight and stability are crucial.

What should I consider when choosing a cast iron counterweight?

When choosing a cast iron counterweight, it is essential to consider:

- The weight capacity required for your specific application

- The dimensions of the counterweight

- The quality of the cast iron used to make the counterweight

It is also important to choose a reputable supplier who can provide a high-quality product that meets your needs.

How are cast iron counterweights made?

Cast iron counterweights are made through a process of melting iron and pouring it into a mold. After the iron cools and hardens, the mold is removed, and the counterweight is finished with a grinding and smoothing process. Quality control is essential throughout the manufacturing process to ensure the counterweights meet the necessary standards.

Can I install cast iron counterweights myself?

While it is technically possible to install cast iron counterweights yourself, it is recommended to seek professional help in most cases. Improper installation can lead to safety hazards and reduce the effectiveness of the counterweights.

Where can I find quality cast iron counterweights for sale?

Quality cast iron counterweights can be found through reputable suppliers and manufacturers. Do your research and choose a supplier with a proven track record of providing high-quality products that meet industry standards.

Summary and Conclusion

Overall, cast iron counterweights offer numerous benefits in various industries and applications. From providing stability and balance in mechanical systems to enhancing safety in agricultural settings, cast iron counterweights play a crucial role in optimizing performance and efficiency.

It’s important to choose high-quality counterweights that are well-crafted and durable to ensure optimal results. When integrating counterweights into your project, be sure to consider weight capacity, dimensions, and proper placement for maximum effectiveness.

While cast iron counterweights can greatly improve your project’s functionality and safety, it’s also crucial to be aware of potential drawbacks and risks associated with using inferior or improperly manufactured counterweights. Always choose quality over cost when it comes to counterweights.

Frequently Asked Questions About Cast Iron Counterweights

Here are some common questions about cast iron counterweights:

Q: What are cast iron counterweights used for?

A: Cast iron counterweights are used to provide stability and balance in various mechanical systems and equipment, as well as to enhance safety in agricultural settings.

Q: How do I choose the right cast iron counterweight for my project?

A: When choosing a cast iron counterweight, consider weight capacity, dimensions, and material quality. It’s also important to choose a reputable supplier that offers high-quality counterweights.

Q: How are cast iron counterweights made?

A: Cast iron counterweights are typically made through a process of melting iron, molding it into the desired shape, and then finishing and painting it as needed.

Q: Can cast iron counterweights be customized for my specific project?

A: Yes, many suppliers offer custom cast iron counterweights to meet the specific needs of your project.

Overall, cast iron counterweights are a valuable asset in many industries and applications. By choosing quality counterweights and understanding their proper usage, you can enhance the efficiency, safety, and overall success of your project.