At our company, we specialize in providing expert solutions for gearbox housing casting. Our team of professionals is committed to delivering high-quality castings that meet the specific needs of our clients. We employ optimal casting processes and use the best casting materials to ensure that our gearbox housing solutions are durable, efficient, and corrosion-resistant.

Our casting methods and production processes are carefully designed to produce castings that meet the precise specifications required for gearbox housings. We work with a range of casting materials, including gray iron and aluminum alloys, to achieve the desired mechanical properties and corrosion resistance that gearbox housings require.

Key Takeaways

- Gearbox housing casting requires expertise and optimal casting processes to achieve high-quality, durable castings.

- The choice of casting material is critical for ensuring the mechanical properties and corrosion resistance required for gearbox housings.

- Our team of professionals is committed to delivering tailored solutions for all your gearbox housing casting needs.

Understanding Gearbox Housing Casting

At our company, we specialize in providing expert solutions for gearbox housing casting. Understanding the process and materials involved is essential to achieve optimal results.

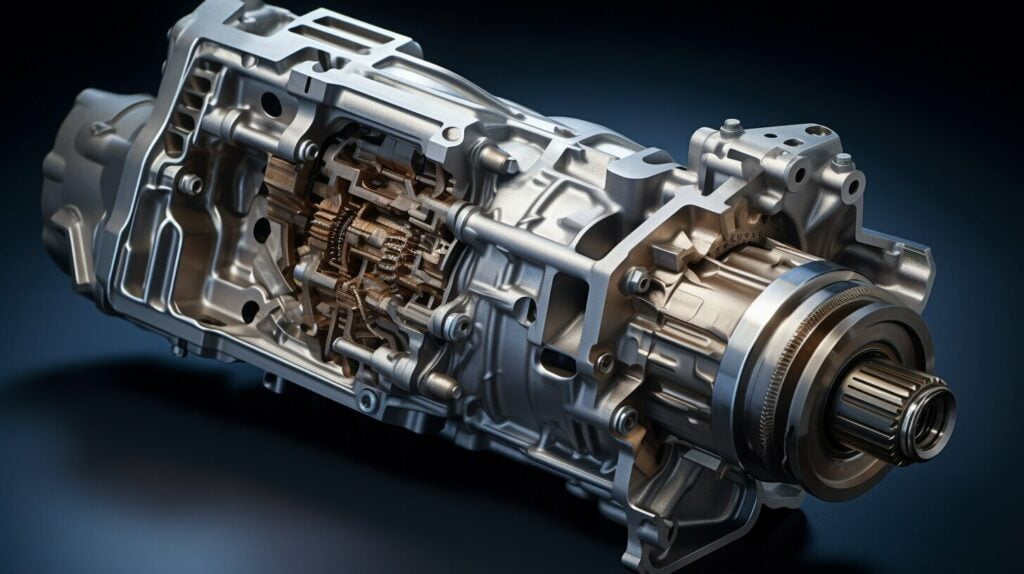

We offer different casting types to suit specific needs, such as die casting and high-pressure casting. These methods allow us to cast various materials, including aluminum and steel alloys. Achieving the right mold is crucial to producing high-quality castings and components used in gearbox housing.

Our expertise in material selection is key to producing high-performing gearbox housings. We use alloys that offer superior mechanical properties and are specifically suited to the processing and torque requirements of a gearbox.

The casting process is vital to achieving the ideal outcome. The process involves pouring the material at the right temperature, carefully controlling the cooling water, and considering appropriate wall thickness. Precision in casting ensures the proper fit and function of gears, motors, and other components within the gearbox housing.

At our company, we place emphasis on the advantages of gray iron casting for gearbox housing applications. Gray iron offers exceptional mechanical properties and enhances the overall performance and durability of gearbox housing castings. The specific casting process involved when working with gray iron enables us to achieve the best results.

CNC machining is critical in refining and enhancing castings. It allows us to achieve precise dimensions and smooth surfaces, ensuring high-quality gearbox housing that meets exact specifications.

“Understanding the process and materials involved in gearbox housing casting is essential to achieve optimal results.”

Corrosion resistance is a significant factor in protecting gearbox housing from environmental factors and extending its lifespan. Choosing the right casting material, such as aluminum alloys, can improve corrosion resistance and provide long-lasting benefits.

Whole cast gearbox housings offer structural integrity and overall performance advantages. To achieve optimal results, the casting process is heavily involved.

Aluminum alloys offer lightweight solutions for gearbox housing, making them ideal for reducing weight without compromising on strength.

Choosing the right casting process is a critical decision that can impact the final product’s strength, durability, and performance. At our company, we guide our clients in making informed decisions to achieve optimal results.

Importance of Material Selection

At our company, we understand that selecting the right materials for gearbox housing casting is crucial to achieving optimal performance. The materials used can impact the processing, equipment support, and torque capacity of the gearbox.

We have a wide range of alloys and materials available to produce castings that meet the specific needs of our clients. For example, we offer superior aluminum alloys that provide high strength-to-weight ratio and excellent corrosion resistance. We also produce castings using steel alloys, which offer exceptional durability and heat resistance.

Our expertise in material selection ensures that we always choose the right material for the specific application. For instance, when producing gearbox housing for machining equipment, we use materials that can withstand high levels of processing, shock, and vibration.

In summary, choosing the right casting material is critical to the performance and longevity of gearbox housing castings. With our deep knowledge and expertise in material selection, we offer tailored solutions that match the unique requirements of our clients.

Optimal Casting Process

At our company, we understand that the casting process is critical to producing high-quality gearbox housing. An optimal casting process requires careful consideration of various factors, including pouring temperature, cooling water, and wall thickness. Precision in casting is also paramount to ensure the proper fit and function of gears, motors, and other components within the gearbox housing.

First, the pouring temperature must be carefully controlled to achieve the desired properties in the castings. The correct temperature can vary depending on the casting material and can affect factors such as mechanical properties and corrosion resistance. Our experienced technicians use advanced equipment and expertise to ensure the correct pouring temperature is maintained throughout the casting process.

Second, the cooling water is crucial in ensuring the optimal casting process. The right cooling water ensures that the casting cools at the correct rate, preventing defects such as shrinkage or an uneven surface. Our team uses the latest technology to monitor the cooling water and ensure that it meets the necessary standards.

Finally, wall thickness is another crucial factor that can impact the production of high-quality gear housing. Our team is adept at understanding the right wall thickness for each project and delivers castings that meet the exact specifications of the client. We use advanced technology and the right casting materials, such as gray iron or aluminum alloys, to achieve optimal wall thickness and mechanical properties.

Through an optimal casting process, we deliver gearbox housing castings that meet the highest standards of quality and performance. Whether using aluminum or steel alloys or die-casting or high-pressure casting methods, our team of experts ensures that the casting process is optimized for each project. By prioritizing precision, attention to detail, and advanced technology, we provide our clients with reliable and efficient gearbox housing solutions.

Advantages of Gray Iron Casting

Gray iron has become a popular casting material for gearbox housing due to its superior mechanical properties. We offer expert solutions using gray iron that result in high-quality, durable castings for your gearbox housing needs.

Our casting process involves meticulously controlling the pouring temperature, cooling water, and wall thickness to ensure the right fit and function of gears, motors, and other components within the gearbox housing. The result is a precisely crafted casting that meets your exact specifications.

| Advantages of Gray Iron Casting for Gearbox Housing: |

|---|

| Superior mechanical properties: Gray iron offers higher strength and wear resistance than other cast iron materials, making it an ideal choice for applications requiring durability and longevity. |

| Optimized casting process: Our expert team applies the optimal casting process to ensure precise dimensions and smooth surfaces of gearbox housing castings. |

| Enhanced performance: Gray iron provides the necessary mechanical support to process high torque and achieve the desired form, ensuring your gearbox runs efficiently and effectively. |

Choose our team for your gearbox housing casting needs, and experience the benefits of using gray iron as your casting material. Contact us today to learn more about our expert solutions.

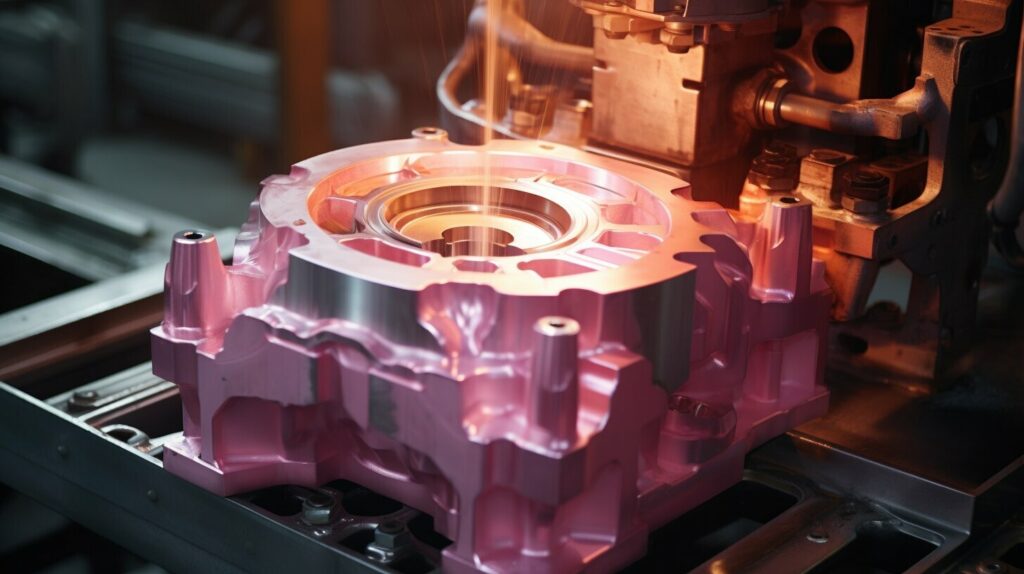

The Role of CNC Machining

At our company, we understand that high-quality gearbox housing castings require not only expert casting processes but also precision CNC machining. CNC machining is an important step in the production process, allowing us to refine and enhance the castings to meet exact specifications.

Our team of professionals utilizes the latest in CNC machining technology to achieve precise dimensions and smooth surfaces on all gearbox housing castings. We understand the importance of producing castings that not only meet but exceed industry standards and client expectations.

Through the combination of casting and CNC machining, we are able to provide gearbox housing castings that are of the highest quality and meet the unique needs of our clients. Our state-of-the-art equipment and experienced technicians allow us to produce castings that are tailored precisely to the specific requirements of each client.

Our commitment to excellence and attention to detail is reflected in our use of CNC machining. We believe that this step in the production process is essential to delivering gearbox housing castings that are of unparalleled quality and performance.

| CNC Machining | Benefits |

|---|---|

| Precision machining of gearbox housing castings | – Ensures exact dimensions and smooth surfaces |

| State-of-the-art equipment and experienced technicians | – Tailored solutions for unique client requirements |

| Exceeds industry standards and client expectations | – Deliver gearbox housing castings of unparalleled quality and performance |

With our expertise in both casting and CNC machining, we guarantee that your gearbox housing castings will be of the highest quality, meeting all of your specific needs and requirements.

Enhancing Corrosion Resistance

At our company, we understand the significance of corrosion resistance in gearbox housing castings. The right casting material can protect against environmental factors, extending the lifespan and performance of your gearbox housing.

We offer a range of casting materials, including aluminum alloys, which are known for their superior resistance to corrosion. Our team of experts can help you choose the optimal casting material to meet your specific needs.

By selecting the right casting material, you can achieve high-quality gearbox housing castings that maintain their structural integrity and performance even in harsh environments. Contact us today to learn more about our solutions for enhancing corrosion resistance in gearbox housing.

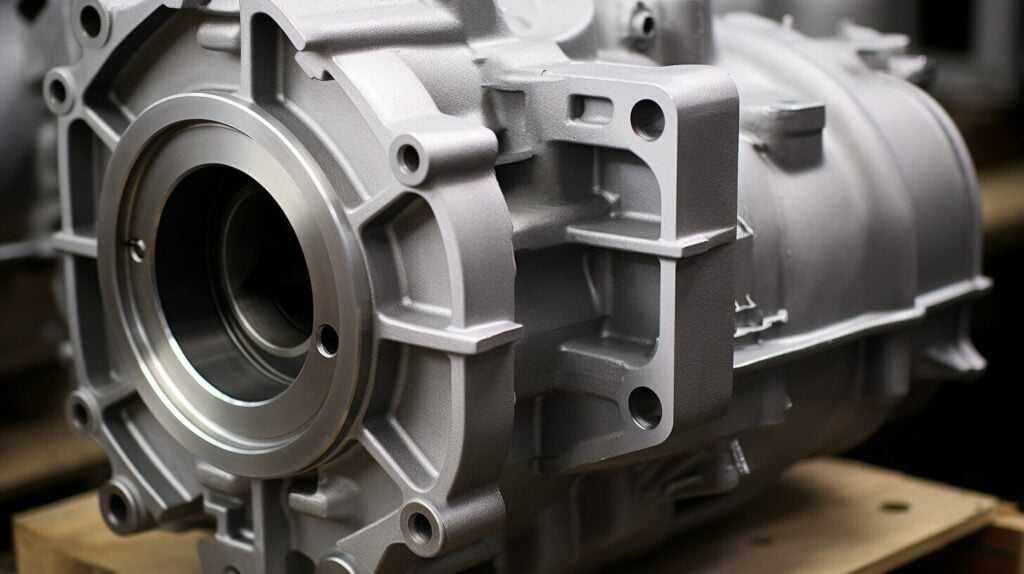

Producing Whole Cast Gearbox Housings

In order to ensure the seamless integration of the transmission system, whole cast gearbox housings are produced using a specific casting process. This process involves pouring the molten metal into a single mold to create the entire housing in one piece. The result is a structurally superior housing that is better able to withstand the stresses and strains of operation.

The production process begins with the creation of a mold that is designed to the exact specifications of the gearbox housing. The mold is then carefully prepared to ensure that the molten metal will flow smoothly and evenly throughout the entire mold. This is crucial to achieving a seamless housing that is free from defects and weak points.

| Pouring Temperature | Cooling Water | Wall Thickness |

|---|---|---|

| The pouring temperature must be carefully controlled to ensure that the molten metal flows smoothly and evenly throughout the mold. | The cooling water is circulated throughout the mold to help the metal solidify and take on its final form. The water temperature and flow rate must be carefully controlled to prevent any warping or distortion of the housing. | The wall thickness of the housing must also be carefully controlled to ensure that it is strong enough to withstand the stresses of operation without being too heavy or bulky. |

The result of this process is a high-quality gearbox housing that is free from defects and able to provide superior performance and durability. At our company, we specialize in producing whole cast gearbox housings using the latest casting processes and materials. We work closely with our clients to ensure that our castings meet their exact specifications and provide the performance and reliability they require.

Image source: https://gpcastings.com/gearbox-housings/

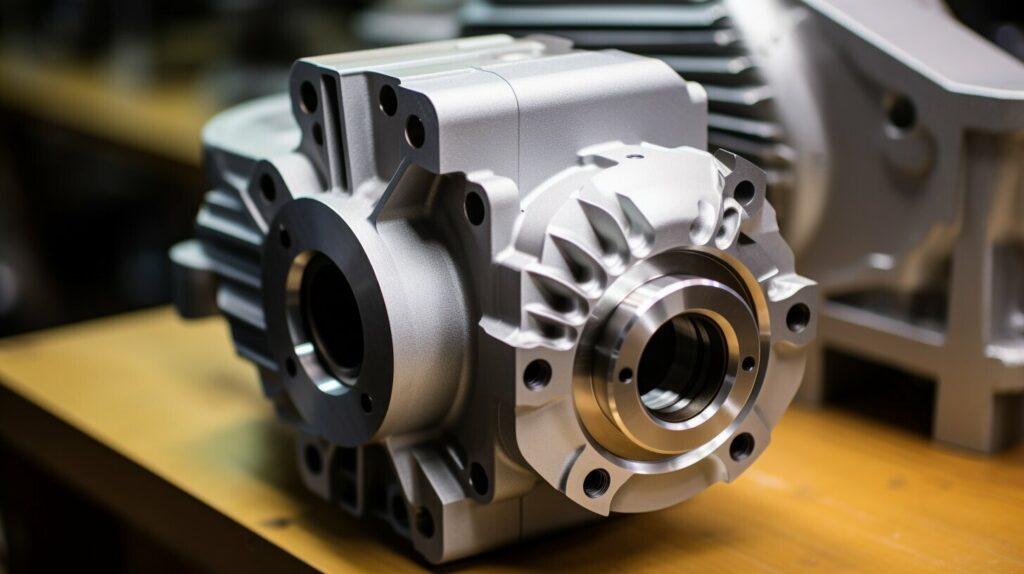

Aluminum Alloy Casting for Lightweight Solutions

At our company, we understand the importance of balancing strength and weight in gearbox housing applications. That’s why we offer aluminum alloy casting as a lightweight solution for our clients.

Aluminum alloys are known for their high strength-to-weight ratio, making them ideal for reducing weight without sacrificing durability. Our team of experts will work with you to select the right aluminum alloy material and casting process for your specific needs.

Our aluminum alloy gearbox housing castings are produced using the optimal casting process, ensuring precision and consistency in wall thickness and mechanical properties. Our high-quality castings are further refined with CNC machining to meet the exact specifications and dimensions required for your gearbox housing application.

Using aluminum alloy as a casting material in gearbox housing offers several benefits. Firstly, it reduces the weight of the component, resulting in improved fuel efficiency and overall vehicle performance. Additionally, the corrosion-resistant properties of aluminum alloys provide added protection and extend the lifespan of the gearbox housing.

At our company, we pride ourselves on delivering tailored solutions that meet the unique needs of our clients. If you require lightweight gearbox housing solutions, our aluminum alloy casting process is the optimal choice for your needs. Contact us today to learn more about how we can enhance your gearbox housing production process.

Choosing the Right Casting Process

Choosing the right casting process is a crucial step in ensuring the optimal performance and durability of gearbox housing. At Our Company, we offer a range of casting processes to meet specific client needs and requirements.

When deciding between casting types such as aluminum or steel, it is important to consider the specific material properties and their impact on the final product. For example, aluminum alloys offer superior corrosion resistance and are ideal for producing lightweight gearbox housing solutions.

On the other hand, steel alloys are known for their strength and durability, making them a great choice for heavy-duty applications. The optimal casting process will depend on factors such as the material, the casting method, and the specific application requirements.

Our team of experts will work closely with clients to choose the casting process that best suits their needs, ensuring the production of high-quality gearbox housing that meets exact specifications. Contact us today to learn more.

Conclusion

At our company, we understand the importance of gearbox housing casting and offer expert solutions tailored to meet our clients’ specific needs. Our focus on optimal casting processes and materials ensures that our castings are of the highest quality, with superior mechanical properties and corrosion resistance.

We have a comprehensive understanding of different casting types, materials, and CNC machining processes, and our expertise allows us to produce whole cast gearbox housings that are structurally sound and integrated, providing superior performance and durability.

Whether you require aluminum or steel alloys or are interested in lightweight solutions through the use of aluminum alloys, we are equipped to offer the best solutions. Our commitment to excellence means that we offer a range of casting solutions to suit your gearbox housing needs, from high-pressure casting to die casting and more.

If you’re in the market for gearbox housing castings, we encourage you to reach out and explore our solutions. Our experienced team is ready to provide tailored recommendations and solutions that meet your requirements and exceed your expectations.

KT-Foundry’s dedication to customer service has been a cornerstone of its success. The gearbox housings produced by the company have garnered praise and recognition from customers who value both the product’s reliability and the seamless customer experience provided. The ability to tailor gearbox housings to meet specific requirements has also contributed to the company’s reputation as a preferred manufacturer.

FAQ

Q: What is gearbox housing casting?

A: Gearbox housing casting is the process of creating gearbox housings using various casting methods, such as die casting or high-pressure casting. It involves pouring molten materials, such as aluminum or steel alloys, into a mold to form the desired shape of the gearbox housing.

Q: What are the advantages of gearbox housing casting?

A: Gearbox housing casting offers several advantages, including corrosion resistance, high-quality castings, and the ability to produce whole cast gearbox housings. It allows for precise dimensions, smooth surfaces, and the integration of gears, motors, and other components within the housing.

Q: How does material selection impact gearbox housing casting?

A: The choice of materials for gearbox housing casting is crucial as it affects the processing, equipment support, and overall performance of the gearbox. Different materials, such as aluminum alloys or gray iron, have specific properties and advantages that need to be considered.

Q: What is the optimal casting process for gearbox housing?

A: The optimal casting process for gearbox housing involves considerations such as pouring temperature, cooling water, and wall thickness. Precision in casting is essential to ensure the proper fit and function of gears, motors, and other components within the gearbox housing.

Q: What are the advantages of using gray iron for gearbox housing casting?

A: Gray iron offers superior mechanical properties, enhancing the performance and durability of gearbox housing castings. It has excellent corrosion resistance and can withstand high loads, making it an ideal material for gearbox housing applications.

Q: How does CNC machining play a role in gearbox housing casting?

A: CNC machining is used in gearbox housing casting to refine and enhance the castings. It ensures precise dimensions and smooth surfaces, resulting in high-quality gearbox housing that meets the exact specifications of clients.

Q: Why is corrosion resistance important in gearbox housing castings?

A: Corrosion resistance is crucial in gearbox housing castings to protect them from environmental factors and extend their lifespan. Materials such as aluminum alloys offer superior resistance against corrosion, ensuring long-term durability.

Q: Can whole cast gearbox housings be produced?

A: Yes, whole cast gearbox housings can be produced using specialized casting processes. This ensures a seamless and integrated housing for the transmission system, offering structural integrity and improved performance.

Q: What are the benefits of using aluminum alloys for gearbox housing casting?

A: Aluminum alloys are lightweight yet strong, making them ideal for producing lightweight gearbox housing solutions. They offer fuel efficiency, improved vehicle performance, and reduced weight without compromising strength.

Q: How do I choose the right casting process for gearbox housing?

A: When choosing the right casting process for gearbox housing, consider factors such as the desired material, casting type (e.g., die casting or high-pressure casting), and the specific requirements of your project. Each casting process has its own strengths and limitations, so it’s important to make an informed decision.