At KT-Foundry, we’re immersed in the production of gray iron castings that serve as a backbone in construction and infrastructure works. With our cast iron parts being a staple in machinery that performs tasks ranging from lifting foundations to connecting electrical guide wires and traffic signal production, our commitment to enhancing structures like bridge platforms with cast components is paramount. Our Wichita, KS-based ISO 9001 certified foundry reaches across America, offering OEMs top-of-the-line castings and comprehensive services from design to full assembly inclusive of machining, heat treating, and coating.

Key Takeaways

- Gray iron castings play a crucial role in construction and infrastructure durability

- KT-Foundry offers comprehensive services from design to full assembly

- Our ISO 9001 certified foundry provides top-quality castings to OEMs in America

- Gray iron cast parts are used in a variety of applications, such as lifting foundations and traffic signal production

- KT-Foundry’s commitment to excellence extends from design to customer service

The Vital Role of Gray Iron Castings in Heavy Construction

At the forefront of heavy construction applications, gray iron castings are known for their versatile and durable nature. They not only ensure compliance with industry standards and certifications but also offer the robustness required for large-scale projects, such as bridge infrastructures and foundation lifts. In this section, we will discuss how our cast iron parts comply with rigorous standards, their indispensable roles in various construction applications, and KT-Foundry’s unwavering commitment to high-quality cast parts.

Adhering to Industry Standards and Certifications

Our gray iron castings are manufactured to meet and surpass industry standards, ensuring adherence to specifications from organizations like ASTM and AASHTO. Additionally, our strict quality control programs emphasize the need to continuously focus on maintaining the superior quality of our cast iron parts. Our adherence to internationally acclaimed certifications, such as the ISO 9001, attests to our dedication to providing trustworthy cast components to our partners.

From Foundation Lifts to Bridge Support – Gray Iron’s Versatility

| Application | Description |

|---|---|

| Foundation Lifts | Gray iron cast components provide support and strength to the foundation lifting process, ensuring stability and precision in heavy construction projects. |

| Bridge Infrastructures | Our cast iron parts are instrumental in stabilizing bridge infrastructures, being an integral part of the support systems that ensure safety and longevity. |

| Electrical Infrastructure | Gray iron parts form the backbone of various electrical infrastructure systems, including electrical guide wires and traffic signal production, providing reliable performance in challenging environments. |

KT-Foundry’s Commitment to High-Quality Cast Parts

As a leading provider of gray iron cast parts, we at KT-Foundry take pride in our unwavering commitment to consistent quality and excellence. In alignment with our ISO 9001 certification, we continue to refine our processes, from design to full assembly, inclusive of machining, heat treating, and coating. By choosing KT-Foundry, our partners not only receive superior, durable cast iron components but also garner the trust and confidence that comes with our longstanding dedication to our craft.

Durability and Cost-Effectiveness of Gray Iron in Infrastructure

Gray iron’s inherent durability and cost-effectiveness come together to make this material a top choice for a wide range of infrastructure projects. In particular, gray iron’s impressive load-bearing capacity and budget-friendly nature make it a wise option for diverse applications, ranging from water meter covers to fire hydrant parts. This marriage of durability and affordability is fortified by the fact that gray iron castings from KT-Foundry utilize a high percentage of recycled materials, cementing our position as a provider of sustainable construction materials in infrastructure development.

- Substantial load-bearing capacity

- Lower cost compared to other metals

- High percentage of recycled materials used in production

- Adaptable to various applications

Let’s take a closer look at some examples of gray iron’s stellar performance as a versatile and cost-effective option for contemporary infrastructure projects:

| Application | Gray Iron Advantages |

|---|---|

| Water Meter Covers | Resists corrosion, suitable for underground environments |

| Fire Hydrant Parts | Exceptional durability, capable of withstanding high pressures |

| Manhole Covers | Withstands immense loads, suitable for heavy vehicle traffic |

| Pipe Fittings | Ease of machinability, compatibility with various piping materials |

In conclusion, gray iron’s resolute durability, cost-effectiveness, and sustainability make it an indispensable material for infrastructure projects. At KT-Foundry, we stand by our commitment to quality gray iron castings as we continue to drive the development of sustainable and lasting infrastructure solutions for our partners.

Gray Iron Castings Microstructure and Mechanical Properties

The distinction and performance of gray iron castings from KT-Foundry stem from the features of their microstructure and mechanical properties. In this section, we delve into the flake graphite microstructure and its impact on tensile strength and damping capacity in gray iron.

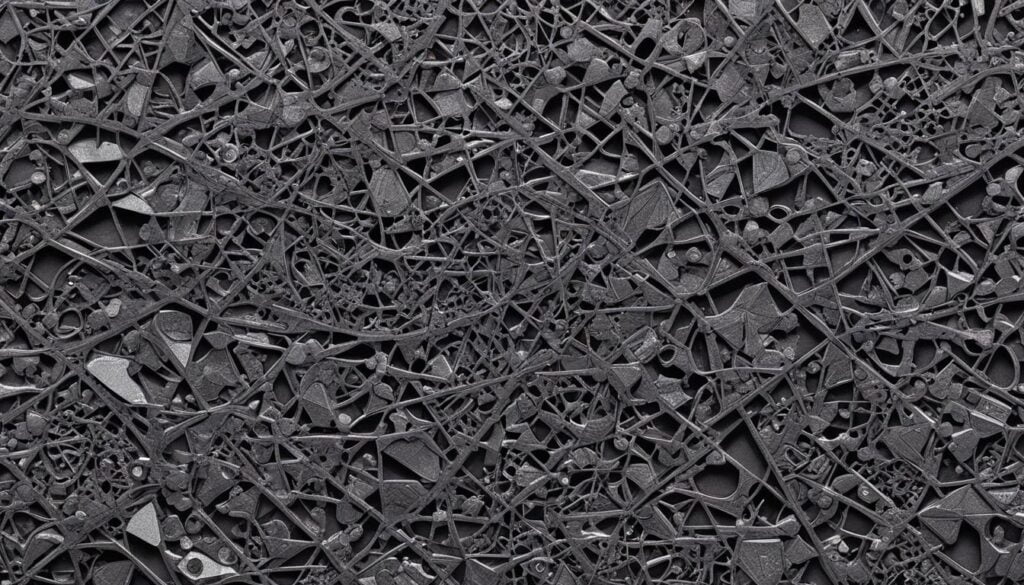

Understanding the Flake Graphite Microstructure

One of the key factors behind gray iron’s attributes is its flake graphite microstructure. This structure is characterized by a matrix of graphite flakes dispersed within the iron. The formation of graphite flakes is influenced by the controlled carbon and silicon content and the cooling rate during the casting process. Consequently, this microstructure results in remarkable machinability and hardness, making gray iron a versatile and essential material in various construction and infrastructure projects.

Tensile Strength and Damping Capacity of Gray Iron

When addressing the mechanical properties of gray iron, it’s important to highlight its tensile strength and damping capacity. Gray iron exhibits a tensile strength ranging between 20,000 to 60,000 psi, providing reliable support for construction machinery and infrastructure components. Although gray iron isn’t measured for yield strength, its tensile strength remains a crucial determinant of its performance.

Furthermore, gray iron boasts a high damping capacity, which plays a vital role in reducing vibrations in moving structures and machinery. This attribute facilitates a quieter and stress-minimized environment – a critical aspect for machines used in construction and infrastructure projects.

In conclusion, gray iron castings’ microstructure and mechanical properties are essential factors that contribute to their widespread use and high performance in construction and infrastructure-related applications. Understanding these properties is fundamental for industries relying on durable and capable materials to meet their project demands.

Innovative Uses of Gray Iron Castings in Modern Constructions

Gray iron castings play a vital role in modern construction, expanding beyond their traditional applications to showcase remarkable versatility in innovative applications and aesthetic construction elements. As a result, modern building materials created using gray iron can provide not only strength and durability but also an appealing visual element in a variety of constructions.

Where Gray Iron Castings Outperform Alternatives

Gray iron’s versatility is most apparent in applications where it surpasses the performance of alternative materials. For instance, weights and counterweights, powertrain components, and suspension systems witness the impressive capabilities of gray iron in ensuring stability and reliability. Its ability to withstand wear and tear, coupled with its favorable mechanical properties, gives it an edge when it comes to enduring the rigors of regular operation.

Unveiling the Esthetic Appeal in Structural Applications

At KT-Foundry, we understand the importance of combining function with visual appeal, leading us to explore gray iron’s aesthetic potential in various architectural aspects. Building facades, ornamental table legs, and other decorative features can be created using gray iron castings, highlighting a unique merger of utility and appearance. The fluidity of gray iron during casting facilitates the creation of diverse designs that cater to both functional requirements and artistic visions.

Gray iron’s adaptability extends beyond brute strength to where its applications outshine alternatives, such as in weights and counterweights, powertrain components, and suspension systems. Its fluidity during casting allows for a spectrum of designs, ensuring both functional strength and visual appeal in manifold construction scenarios.

In summary, gray iron castings offer unmatched innovation in modern constructions, pushing boundaries in applications and aesthetics alike. By recognizing and embracing its potential in multiple domains, we at KT-Foundry are committed to providing cutting-edge gray iron solutions that optimally serve modern construction and architectural demands.

Conclusion

As we reach the end of our exploration into the world of gray iron castings, it is evident that their diverse capabilities and cost-efficiency make them indispensable in modern construction and infrastructure. With an ever-growing demand for stable, lasting, and environmentally friendly solutions, the advantages of gray iron cannot be overstated.

Positioned at the forefront of industry innovation and excellence, KT-Foundry provides consistently reliable, versatile, and quality gray iron casting solutions. Our unwavering commitment to maintaining the highest industry standards, coupled with our desire to exceed expectations through innovative applications, ensures that we remain a vital partner in supporting the nation’s infrastructure development.

In sum, the importance of gray iron castings extends across myriad sectors and applications. Together with our partners, we at KT-Foundry are proud to contribute to the ongoing evolution and progress in construction and infrastructure, delivering exceptional value and driving sustainable growth for the betterment of our communities.

FAQ

What are the benefits of using gray iron castings in construction and infrastructure?

Gray iron castings offer durability, cost-effectiveness, and versatility, making them an ideal choice for various applications in construction and infrastructure projects. They have an inherent load-bearing capacity and heightened mechanical properties while allowing for sustainable production through the use of recycled materials.

How does KT-Foundry ensure the quality of their cast iron parts?

KT-Foundry is an ISO 9001 certified foundry, adhering to rigorous industry standards and specifications, such as ASTM and AASHTO. We maintain strict quality control programs and provide comprehensive services ranging from design to full assembly, including machining, heat treating, and coating for our cast iron parts.

What is the microstructure of gray iron, and how does it contribute to its mechanical properties?

The microstructure of gray iron consists of flake graphite, which offers excellent machinability and influences hardness. This microstructure, determined by controlled carbon and silicon content and the cooling rate during casting, impacts the material’s mechanical characteristics, including its tensile strength and damping capacity.

In what ways does gray iron outperform alternative materials in construction applications?

Gray iron castings excel in applications involving weights and counterweights, powertrain components, and suspension systems. Its fluidity during casting allows for a wide range of designs, ensuring both functional strength and visual appeal in various construction scenarios. Gray iron also boasts its high damping capacity, which reduces vibration in moving structures and machinery.

How does KT-Foundry contribute to sustainable construction and infrastructure development?

At KT-Foundry, we use a high percentage of recycled materials in our gray iron castings production, promoting a sustainable approach to infrastructure development. By offering durable, cost-effective, and versatile solutions, we support the growing demand for environmentally-friendly materials in construction projects.