At KT-Foundry, we recognize the growing importance of gray iron components in the automotive manufacturing sector. The automotive iron casting market continues to expand, driven by the demand for robust and durable automotive solutions that can withstand the harsh conditions inside vehicles. Our gray iron castings contribute to the production of lighter, more fuel-efficient vehicles, aligning with the current trend towards electric vehicles that require lighter components for enhanced battery efficiency and range.

Key Takeaways

- Gray iron castings play a critical role in the production of strong and durable automotive components.

- The automotive iron casting market is expanding due to the increasing demand for high-quality parts.

- Our gray iron castings aid in manufacturing lighter vehicles for better fuel efficiency and battery effectiveness in electric cars.

- KT-Foundry offers bespoke gray iron casting solutions designed to meet the unique requirements of each client.

- Sustainability and eco-friendly practices are integral to our manufacturing approach, ensuring a minimal carbon footprint.

The Integral Role of Gray Iron Castings in Modern Vehicles

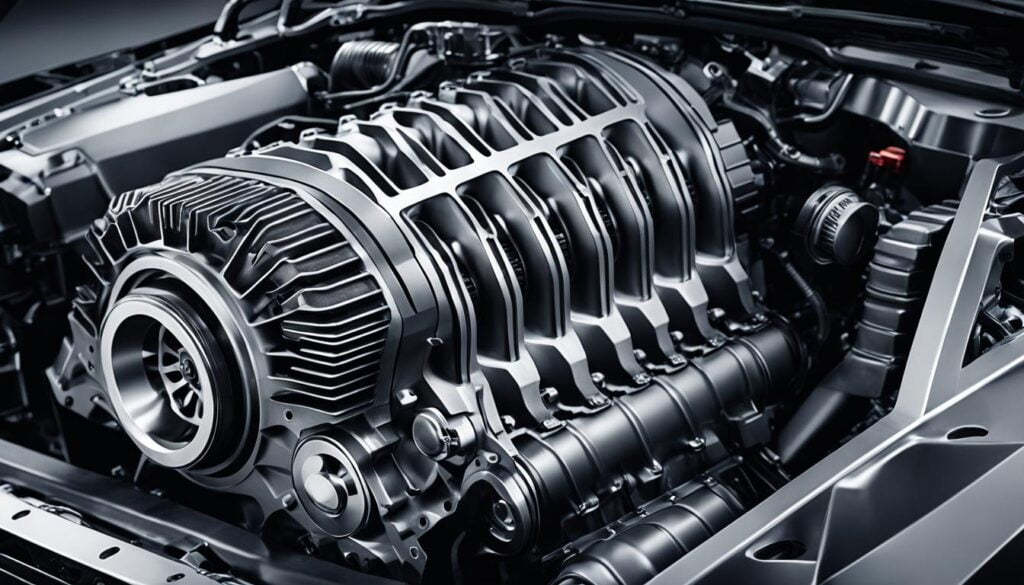

Gray iron castings serve as a crucial component in the automotive industry, offering superior strength and durability for various vehicle parts. At KT-Foundry, we specialize in producing high-strength automotive parts in the form of gray iron castings which can withstand the rigorous demands of daily vehicle operation. These castings contribute to the production of lightweight iron castings, striking the perfect balance between weight and strength for optimal vehicle performance.

Importance of Strength and Durability in Automotive Components

As contemporary vehicles must cope with varying road conditions and the wear and tear of frequent use, the components utilized in their manufacturing process should be strong, durable, and long-lasting. Gray iron castings provide unmatched durability and strength, ensuring automotive manufacturers a consistent, high-quality material choice for crucial vehicle parts, such as engine blocks and brake systems.

Weight Considerations and Fuel Efficiency

One of the top priorities in vehicle design is achieving a balance between weight and strength. Lightweight iron castings contribute to this goal by offering strong and durable components while minimizing overall vehicle weight. This helps the automotive industry progress towards greater fuel efficiency and reduced emissions, which are key aspects of automotive industry standards.

Adoption of Gray Iron Castings for Emission Regulation Compliance

Regulatory bodies around the world have been implementing stricter vehicle emission control standards to tackle environmental concerns. The utilization of gray iron castings in automotive components plays a vital role in meeting these regulations by enabling the creation of lighter and more fuel-efficient vehicles with reduced emissions. Thus, gray iron castings serve as an integral part of the ongoing effort to develop environmentally-friendly vehicles in the modern automotive landscape.

Technological Advancements in Automotive Iron Casting

Technological advancements significantly impact our production capabilities at KT-Foundry. We leverage cutting-edge advanced casting technologies, automated molding techniques, and high-precision iron castings to enhance the quality and efficiency of our gray iron castings. These advancements allow us to engineer complex designs with greater precision and less waste, resulting in superior iron casting products.

Through continuous innovation in our casting processes, we underscore our commitment to providing our customers with components that meet the evolving needs of the automotive industry while maintaining the highest quality standards.

One of the most notable advantages of advanced casting technologies is their ability to produce intricate shapes and designs. These capabilities are essential in modern automotive manufacturing, where the demand for lightweight components and complex geometries is increasing. Automated molding techniques enhance our production efficiency and consistency, resulting in higher-quality products and reduced production costs.

High-precision iron castings play a crucial role in the functionality and performance of automotive components. To ensure that our castings meet the high demands of modern vehicles, we invest in state-of-the-art manufacturing equipment and continuously refine our processes. This approach allows us to develop components that not only perform exceptionally well but also adhere to strict automotive industry standards.

- Advanced casting technologies for intricate shapes and designs

- Automated molding techniques for enhanced production efficiency

- High-precision iron castings for superior functionality and performance

At KT-Foundry, we are committed to staying at the forefront of technological advancements in automotive iron casting. Our investment in cutting-edge equipment, processes, and research and development allows us to consistently deliver high-quality, innovative components that meet the unique needs and challenges of the automotive industry.

Gray Iron Castings Offerings by KT-Foundry

At KT-Foundry, we pride ourselves on offering custom engineered iron casting solutions tailored to the unique needs of our clients. Our wide range of castings cater to both OEM and aftermarket support, enabling us to deliver material options that cover the full spectrum of applications. These solutions ensure the durability and reliability our automotive industry customers have come to expect from our gray iron castings.

Custom Engineered Solutions for OEMs and Aftermarket

Our extensive experience allows us to develop bespoke iron castings for original equipment manufacturers (OEMs) and aftermarket industries. We work closely with each client to create high-quality iron castings that meet their exact specifications. Our commitment to customer satisfaction means we focus on even the smallest details, ensuring every component we produce meets our rigorous quality criteria.

Katherine Smith, Automotive Manufacturing Expert

“KT-Foundry’s custom engineered iron castings have consistently exceeded my expectations. Their attention to detail and commitment to customer satisfaction has allowed for seamless integration between their products and automotive components.”

Our Material Grade Variations and Their Applications

We offer grade-specific iron castings to meet diverse application requirements. Our product lineup includes a wide range of materials to ensure optimal performance in every automotive situation. To accommodate different customer needs, we utilize various material grades, including:

- Grade 25: Suitable for parts requiring high tensile strength, such as bearing caps and tie rods.

- Grade 30: Ideal for lightweight components like vehicle frames and brake components.

- Grade 35: Perfect for parts subjected to high-stress, like crankshafts and gear housings.

- Grade 40: The go-to choice for heavy-duty applications, such as engine blocks and transmission cases.

Our gray iron castings are engineered for streamlined performance in components ranging from engine parts and suspension systems to braking assemblies and more. By making use of different material grades, we help our clients create automotive parts that cater to the specific requirements of their vehicles.

KT-Foundry remains dedicated to providing clients with the highest-quality gray iron castings solutions, ensuring optimal performance for the automotive industry. Our commitment to engineered iron casting solutions, coupled with our comprehensive OEM and aftermarket support, positions us as an industry leader in this competitive market.

Driving Innovation with Sustainable Manufacturing Practices

At KT-Foundry, we are committed to achieving automotive manufacturing sustainability in all our processes while producing sustainable iron casting products. Our approach to manufacturing not only focuses on creating the highest quality castings but also ensuring that our methods have a reduced carbon footprint in production and are environmentally responsible. In this pursuit, we continually strive to implement eco-friendly processes and technologies that set the stage for the future of iron castings in an eco-conscious automotive industry.

Implementing Eco-friendly Processes and Reducing Carbon Footprint

Understanding the environmental implications of our business, we have optimized our production methods to minimize waste, emissions, and energy consumption. Some of the steps we’ve taken to reduce our carbon footprint in our iron casting production process include:

- Investing in energy-efficient machinery and equipment

- Implementing advanced waste management and recycling systems

- Utilizing renewable energy sources where possible

- Optimizing production processes to minimize material waste

- Regularly evaluating and updating our environmental policies

By adhering to these principles, we provide our customers with products that are not only of the highest quality but also contribute to a greener manufacturing landscape.

The Future of Iron Castings in an Eco-Conscious Automotive Industry

As the automotive industry continues to prioritize environmental consciousness, the demand for sustainable solutions and materials will grow. As a responsible iron casting manufacturer, we recognize the crucial role we play in shaping the future of the industry, which is why we consistently seek out innovative, environmentally-friendly approaches in our manufacturing processes. Our goal is to stay at the forefront of sustainable iron casting production while meeting the evolving demands of an increasingly eco-conscious automotive sector.

| Focus Area | Current Efforts | Future Plans |

|---|---|---|

| Energy Efficiency | Utilizing energy-efficient machinery and renewable energy sources | Continued investment in clean energy and energy-saving technology |

| Waste Management | Strict waste management and recycling systems in place | Implementation of zero-waste initiatives and circular economy practices |

| Process Optimization | Reducing material waste and optimizing production processes | Adoption of Industry 4.0 technologies and advanced automation |

| Environmental Policies | Regular assessment and updating of environmental policies | Striving for best practices and certifications in sustainability |

In conclusion, our commitment to sustainability and the environment ensures that we remain a trusted partner for automotive manufacturers seeking sustainable iron casting solutions. By continually driving innovation in green manufacturing practices, we aim to build a brighter and environmentally responsible future for the automotive industry and our planet.

Conclusion

In conclusion, gray iron castings are the backbone of the automotive industry, contributing to the creation of vehicles that are robust, efficient, and environmentally responsible. KT-Foundry stands at the forefront of providing industry-leading iron castings, with an emphasis on innovation, sustainability, and customer satisfaction.

Our expertise in custom solutions, a broad spectrum of material grades, and sustainable practices positions us as leaders in a market that values both quality and environmental stewardship. As the automotive sector continues to experience growth, we are prepared to meet its challenges, driving forward the use of gray iron castings in automotive manufacturing.

With our reputation as a quality-driven casting manufacturer, we are committed to serving the ever-evolving needs of the automotive industry. Through continuous innovation, dedication to sustainability, and unwavering customer focus, KT-Foundry is poised to remain a key player in the future of automotive manufacturing, ensuring the seamless integration of gray iron castings into the vehicles of tomorrow.

FAQ

What are the benefits of gray iron castings in automotive manufacturing?

Gray iron castings offer unmatched strength and durability, making them ideal for various vehicle components. They contribute to the production of lightweight, fuel-efficient vehicles, meeting the current market demand for efficient and environmentally friendly solutions.

How do weight considerations and fuel efficiency relate to gray iron castings in the automotive industry?

The balance between weight and strength is crucial in vehicle design. Gray iron castings provide a solution that contributes to lighter vehicles without compromising performance, ultimately improving fuel efficiency and reducing emissions.

How do technological advancements impact automotive iron casting production?

Advanced molding techniques, automation, and high-precision engineering enable more complex designs with greater accuracy and less waste. This results in superior iron casting products that meet the needs of the evolving automotive industry while maintaining high quality standards.

What services and products does KT-Foundry offer in gray iron casting?

KT-Foundry specializes in custom engineered solutions for both OEMs and the aftermarket, with offerings that encompass a broad range of applications. Our expertise covers various material grades and product types, including crankshafts, bearing caps, knuckles, and control arms.

How does KT-Foundry implement sustainable manufacturing practices?

We are committed to sustainability and eco-friendliness in all our operations. By incorporating advanced, clean technologies and optimizing production methods, we reduce our carbon footprint and ensure that our manufacturing processes are environmentally responsible.

What’s the future of gray iron castings in the automotive industry?

As the automotive industry continues to evolve and shift towards electric vehicles and eco-conscious solutions, gray iron castings will remain an integral component. With advances in technology and sustainable practices, manufacturers like KT-Foundry will continue to adapt and develop innovative products and solutions that meet these demands.