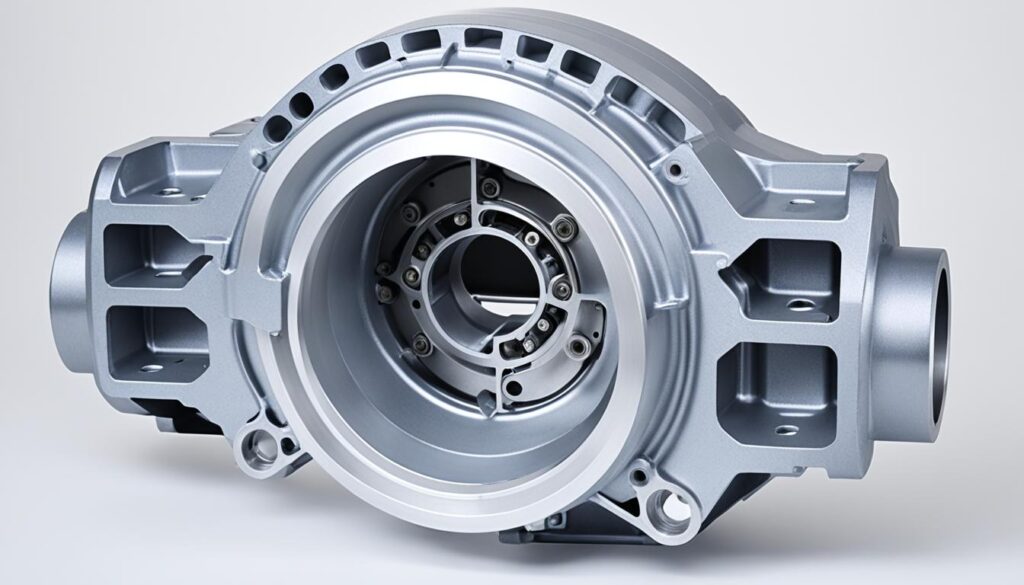

At KT-Foundry, we specialize in providing premium aluminum motor housing solutions that deliver superior protection and performance for demanding industrial applications. Our top-rated aluminum motor housing products are designed to withstand the toughest environments, offering unparalleled durability, strength, and thermal management capabilities.

The use of high-strength alloy casings in motor design and manufacturing has become increasingly popular due to the numerous advantages of aluminum. This lightweight yet durable material is resistant to corrosion, ensuring long-lasting protection for critical motor components. Our precision-engineered motor covers and sturdy motor casing solutions are engineered to provide reliable performance and safeguard the integrity of your industrial motors.

Key Takeaways

- Aluminum motor housings offer superior durability and corrosion resistance

- Lightweight construction reduces overall weight and improves energy efficiency

- Excellent thermal management properties ensure efficient motor operation

- Precise engineering and manufacturing ensure consistent quality and performance

- Versatile applications across various industries, from manufacturing to renewable energy

The Advantages of Aluminum Motor Housings

At KT-Foundry, we understand the importance of utilizing high-quality materials for industrial-grade motor housings. Our aluminum alloy enclosures are designed to provide superior performance and durability, making them a preferred choice for various applications. Aluminum is renowned for its lightweight and durable construction, offering a unique combination of strength and low density.

One of the key advantages of our corrosion-resistant aluminum alloy casings is their ability to withstand harsh environmental conditions. These high-strength aluminum motor enclosures are engineered to resist the effects of corrosive elements, ensuring long-lasting protection for the internal components. Additionally, the low porosity of aluminum contributes to a remarkably low level of noise during operation, providing a quieter working environment.

Lightweight and Durable Construction

Our precision-engineered aluminum shells not only offer exceptional durability but also boast a remarkable level of thermal efficiency. The thermally-efficient aluminum motor covers effectively dissipate heat, ensuring optimal performance and longevity of the motor components. This feature is particularly important in applications where thermal management is crucial for maintaining optimal operating conditions.

“Aluminum alloy enclosures are preferred due to their strenuous resistance to corrosive forces, adequate material density, and low porosity.”

At KT-Foundry, we take pride in our commitment to engineering excellence. Our lightweight and durable aluminum motor housings are meticulously designed and tested to provide unparalleled protection and performance for our customers’ industrial needs.

Top-Rated Aluminum Motor Housing Applications

Aluminum motor housing extrusion is a versatile material with a wide range of applications across various industries. One of the most significant applications is in the automotive industry, where it is used in electric vehicles (EVs) and hybrid vehicles to reduce weight and improve thermal management. Aluminum motor housing extrusion is also used in high-performance sports cars like the Audi R8 to enhance motor performance, efficiency, and reliability.

The aerospace industry also utilizes aluminum motor housing extrusion in various applications, including aircraft engines, satellite propulsion systems, and space launch vehicles, where weight reduction and reliability are critical factors. Additionally, aluminum motor housing extrusion is used in a variety of industrial machinery and consumer electronics applications, such as power tools, home appliances, and computer peripherals, to improve performance and reduce weight.

“Aluminum motor housing extrusion is a game-changer in industries where weight reduction and thermal management are paramount. Its unique properties make it an indispensable material for cutting-edge applications.”

The versatility of aluminum motor housing extrusion is a testament to its superior properties, making it a top choice for a wide range of industries. From the automotive and aerospace sectors to industrial machinery and consumer electronics, this material continues to provide innovative solutions that drive performance and efficiency.

Precision Engineering and Thermal Management

At KT-Foundry, our focus on precision engineering and thermal management is the driving force behind our superior precision-engineered aluminum motor housings. We understand that the key to optimal motor performance lies in effective heat dissipation, which is why we have engineered our thermally-efficient aluminum motor enclosures to provide unparalleled thermal management capabilities.

The high thermal conductivity of aluminum allows for superior heat dissipation in aluminum motor casings, ensuring that motors remain within their optimal temperature range during operation. Our innovative design, featuring strategically placed heat-dissipating ribs on the motor casing, further enhances this thermal management capability, making our aluminum motor housings for optimal thermal management a top choice for a wide range of applications.

“Our precision-engineered aluminum motor housings set the standard for thermal management excellence, delivering uncompromising performance and reliability in even the most demanding environments.”

Whether you’re working in the automotive, aerospace, industrial machinery, or consumer electronics industries, our precision-engineered aluminum motor housings are designed to provide the superior heat dissipation and thermally-efficient performance you need to keep your motors running at their best.

Conclusion

In conclusion, KT-Foundry’s superior aluminum motor housing solutions offer unparalleled durability and efficiency. Our top-rated aluminum motor enclosures are engineered to provide exceptional protection, performance, and reliability for a wide range of industrial applications. With their lightweight yet robust construction, corrosion resistance, and excellent thermal management capabilities, our premium aluminum motor housing products ensure optimal performance even in the most demanding environments.

The versatility and advantages of aluminum make it the ideal material for motor design and manufacturing. KT-Foundry’s aluminum motor housings deliver the perfect balance of strength, thermal management, and energy efficiency, making them the preferred choice for those seeking superior solutions. By investing in our durable and efficient aluminum motor enclosures, our customers can trust that their critical motor components are safeguarded, ensuring long-lasting performance and reliability.

As a leading provider of top-quality aluminum motor housing solutions, KT-Foundry is committed to delivering the best possible products and services to our customers. We take pride in our engineering expertise, attention to detail, and unwavering commitment to customer satisfaction, ensuring that our aluminum motor housing solutions consistently exceed the expectations of our clients.

FAQ

What are the advantages of using aluminum for motor housings?

Aluminum is a lightweight, high-strength material that is resistant to corrosion, and has excellent thermal management properties, making it an increasingly popular choice for motor design and manufacturing.

What type of aluminum alloy is used to create extruded aluminum motor housings?

Industrial-grade aluminum alloy is the material used to create extruded aluminum motor housings at KT-Foundry. Aluminum alloy enclosures are preferred due to their strenuous resistance to corrosive forces, adequate material density, and low porosity.

In what industries are aluminum motor housings commonly used?

Aluminum Motor Housing Extrusion is widely used in the automotive industry for electric vehicles and hybrid vehicles, the aerospace industry for aircraft engines and satellite propulsion systems, and in various industrial machinery and consumer electronics applications.

How do KT-Foundry’s aluminum motor housing solutions provide superior thermal management?

KT-Foundry’s Aluminum Motor Housing Extrusion solutions are precision-engineered to provide superior thermal management and heat dissipation capabilities. The material’s high thermal conductivity allows for better heat dissipation, improving the lifespan and reliability of the motor.

What are the key benefits of KT-Foundry’s premium aluminum motor housing products?

KT-Foundry’s aluminum motor housings offer superior protection, performance, and efficiency, with their lightweight, durable construction, corrosion resistance, and excellent thermal management capabilities, providing reliable and long-lasting protection for internal motor components.