High-chromium alloys and their unique compositions have revolutionized various industries by providing unparalleled strength, hardness, and corrosion resistance. These game-changing alloy steel castings have made significant inroads in a diverse array of applications, ranging from medical implants to heavy machinery components. In this article, we delve into the fundamental aspects of high-chromium alloy composition and how it has transformed material innovation, enabling numerous industrial applications with remarkable corrosion resistance and biocompatibility.

Key Takeaways

- High-chromium alloys offer superior strength, hardness, and corrosion resistance compared to conventional alloys.

- These alloys have found widespread use in diverse industrial applications, including medical implants and heavy machinery components.

- Composition and balance of alloying elements play a vital role in determining high-chromium alloy performance.

- Chromium is a key component of these alloys, significantly augmenting their resistance to corrosion and deterioration.

- Material innovation in high-chromium alloys has paved the way for safer and eco-friendly alternatives that deliver optimal results in varied applications.

- The potential for further developments in high-chromium alloys promises to reshape the future of advanced material science.

The Robust Composition of High-Chromium Alloys

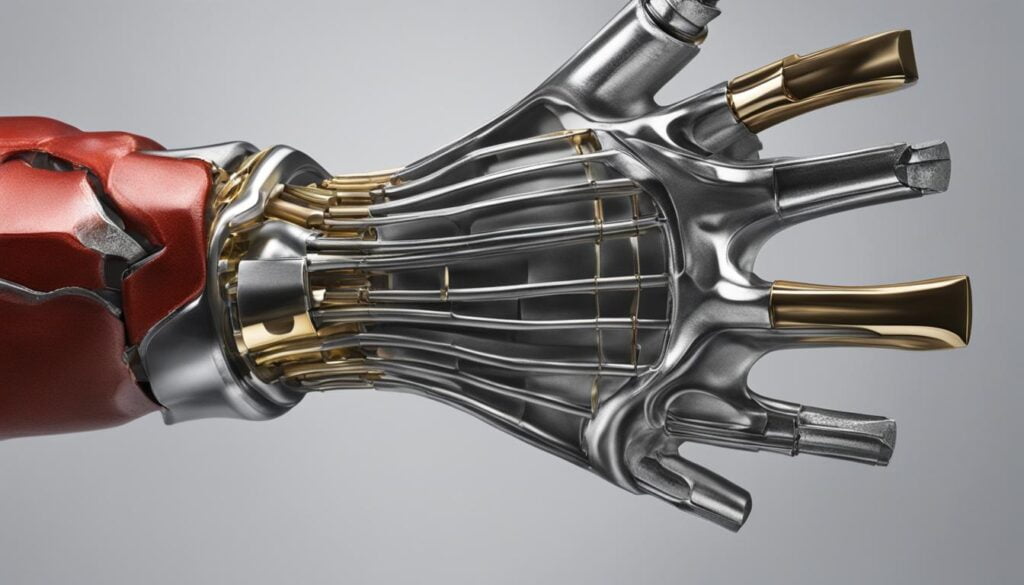

High-chromium alloys, such as cast Co-Cr alloys, are renowned for their exceptional performance in various applications ranging from biomedical implants to dental frameworks. The superior properties of these alloys can be attributed to the optimal balance of cobalt, chromium, molybdenum, and in some cases, nickel. These elements contribute to their integrity and reliability by conferring resistance to both wear and corrosion.

Defining High-Chromium Alloy Characteristics

High-chromium alloys, including Co-Cr, boast characteristics that outshine alternatives like NiCr in terms of strength and hardness, largely due to the inclusion of chromium and molybdenum. These material science breakthroughs have enabled the development of alloys that provide optimal performance in demanding applications such as biomedical implants and dental frameworks.

Carbon Content and Its Impact on Alloy Performance

Modulating carbon content in high-chromium alloys has significant implications on their performance. While carbon is essential in forming hard carbides that aid in abrasion resistance, excessive carbon can hinder the formation of the critical chromium oxide passivation layer that enhances corrosion resistance. Understanding the effects of carbon content in alloys is vital for devising precision strategies to differentiate between cast and wrought Co-Cr alloys.

Carbon management is a critical element in determining the overall performance of high-chromium alloys, particularly concerning their wear resistance and corrosion resistance properties.

Understanding the Role of Chromium in Corrosion Resistance

The primary function of chromium is to enhance an alloy’s corrosion resistance. This is achieved through the formation of a passive layer of chromium oxide, which protects the alloy from aggressive environments. In medical applications, the biocompatibility of these alloys is of paramount importance, and chromium corrosion resistance plays a crucial role in ensuring these alloys maintain a sterile surface amidst corrosive bodily fluids.

- Contributes to the formation of a passive oxide film, enhancing corrosion resistance

- Improves material hardness and wear resistance through the formation of chromium carbides

- Aids in alloy castability, enabling intricate shapes to be produced for specialized applications

Moreover, the addition of molybdenum further bolsters this resistance, expanding the potential applications of Co-Cr alloys across various biomedical functions.

| Element | Function | Impact on Alloy Performance |

|---|---|---|

| Chromium | Corrosion Resistance | Forms a passive oxide film, limits material degradation in aggressive environments |

| Molybdenum | Strength and Hardness | Enhances abrasion resistance, increases overall strength |

| Carbon | Carbide Formation | Increases material hardness, but excessive amount can affect corrosion resistance |

Versatile Applications of High-Chromium Alloys in Industry

The wide-ranging high-chromium alloy uses have allowed its adoption across various industries, where its remarkable properties prove indispensable. Known for their superior abrasion resistance, high-chromium alloys like Co-Cr have found their niche in applications requiring materials with heightened hardness and wear protection.

Biomedical and dental sectors utilize high-chromium alloys for constructing implants in contact with blood and tissue, as well as for casting dental prosthetics. Industrial alloys such as these effectively withstand wear and corrosion while maintaining radial strength.

Co-Cr alloy’s high abrasion resistance owes to its composition—a key feature that sets them apart from other metal alloys. The high-chromium 25% Cr alloy offers outstanding wear protection, making it the go-to choice for abrasive applications.

High-chromium white iron is another example of a highly practical material, offering resistance to abrasion and wear in severe operating environments. With its widespread use across demanding industries, such as mining, concrete recycling, and manufacturing, this alloy represents the benchmark in wear-resistant materials.

High-chromium alloys feature prominently in industries requiring materials capable of enduring abrasion such as mining, concrete recycling, and machinery components.

- Pump and piping applications

- Automotive parts

- Aerospace components

- Power generation equipment

- Chemical processing plants

Below is a table illustrating several high-chromium white iron compositions and their representative abrasion resistance:

| Alloy Composition | Abrasion Resistance |

|---|---|

| 15% Cr | Good |

| 20% Cr | Very Good |

| 25% Cr | Excellent |

In conclusion, high-chromium alloys exhibit significant potential for application across diverse industries due to their excellent wear and corrosion resistance, considerable hardness, and impressive radial strength. With the continuous advancement of material science, these versatile industrial alloys will likely find even more applications in multiple sectors in need of robust materials.

Conclusion: Future Prospects of High-Chromium Alloy Innovations

As we continuously advance in the realm of material science, the prospects for further innovation with high-chromium alloys are promising. Our focus remains on improving various properties such as tensile strength, wear resistance, and environmental impact. By examining the fine balance of alloying elements and engineering methods, we can create alloys capable of superior performance outcomes in diverse industry applications.

Advancing Material Science with High-Chromium Alloys

Material innovation is at the forefront of modern industry advancements, offering remarkable improvements in product performance and durability. High-chromium alloys present as an exciting class of materials, showcasing exceptional corrosion and wear resistance, as well as biocompatibility. Staying attuned to the future developments of these alloys will aid in unlocking new possibilities and bolstering our understanding of diverse material behaviors.

Addressing Environmental and Safety Considerations

Environmental impact and safety concerns continue to gain importance in the development of alloys. It is crucial to design materials that pose minimal risks of cytotoxicity, hypersensitivity, and adverse environmental consequences in order to create more sustainable and user-friendly products. Future research ventures will focus on minimizing the genotoxic potential of chromium alloys, reaffirming their efficacy and safety amidst concerns of metal ion release and potential carcinogenicity. The ultimate goal is to develop surfaces with increased hardness and protective capabilities, ensuring compliance with stringent environmental and safety regulations.

FAQ

What are the primary characteristics of high-chromium alloys?

High-chromium alloys are known for their remarkable corrosion resistance, wear resistance, hardness, and radial strength. They are composed of a balanced mix of cobalt, chromium, molybdenum, and sometimes nickel, which contribute to their reliability and integrity in various applications, such as dental frameworks and medical implants.

How does carbon content impact the performance of high-chromium alloys?

Carbon content has a significant influence on the performance of high-chromium alloys. While necessary for the formation of hard carbides that aid in abrasion resistance, excessive carbon can hinder the formation of the crucial chromium oxide passivation layer that enhances corrosion resistance. This balance in carbon content is a critical differentiating factor between cast and wrought Co-Cr alloys.

What roles do chromium and molybdenum play in high-chromium alloys?

Chromium primarily enhances an alloy’s corrosion resistance by creating a passive layer of chromium oxide, which protects the alloy from aggressive environments. In medical applications, this biocompatibility is essential for resisting corrosive bodily fluids and maintaining a sterile surface. Molybdenum further supports this corrosion resistance, broadening the potential applications of Co-Cr alloys in various biomedical functions.

What industries benefit from the use of high-chromium alloys?

High-chromium alloys are versatile and used across multiple industries, such as the biomedical sector for implants in contact with blood and tissue and dentistry for casting dental alloys. The high-chromium 25% Cr alloy is particularly sought after in abrasive applications, making it a popular choice in industries like mining, concrete recycling, and various machinery components.

What are some future prospects for high-chromium alloy innovations?

Advancements in material science offer ample opportunities for innovation with high-chromium alloys, aiming to improve their resilience, environmental impact, and cost-effectiveness. The focus remains on enhancing mechanical properties, such as tensile strength and wear resistance, while examining the fine balance of alloying elements to achieve superior performance outcomes for demanding industry applications. Additionally, research continues into developing alloys with reduced genotoxic potential, harder and more protective surfaces, and addressing concerns of metal ion release and potential carcinogenicity.