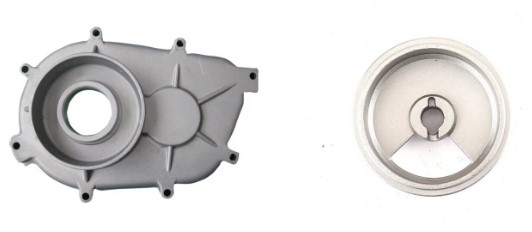

Aluminum die casting is a highly precise and repeatable manufacturing process for producing high-quality cast aluminum. This manufacturing process involves injecting molten aluminum using high-pressure die-casting equipment into a reusable steel mold or die.

The result is a cost-effective, high-quality part with excellent mechanical properties and surface finish.

Aluminum is a popular choice of die-casting material because it has many desirable properties, including a high strength-to-weight ratio, good thermal and electrical conductivity, and good corrosion resistance.

This article will explore the aluminum die-casting process in detail, including its advantages, the steps involved, the types of die-casting machines used for aluminum, and other aluminum casting processes.

Aluminum Die Casting Process

Aluminum castings are used in nearly any industry under high-temperature environments, including aerospace, where strength-to-weight ratio and high performance are critical factors. Because of its aluminum oxide layer, it produces an aluminum casting with excellent corrosion resistance.

They are also used in consumer goods such as electronics, where aluminum’s thermal conductivity properties make it an ideal material for heat sinks and other components.

Creating Die Cast Mold for Aluminum Castings

Creating die-casting dies or die-casting tooling is designed using computer-aided design (CAD) software, allowing the designer to create a detailed cast aluminum model. The die-cast design considers part geometry, draft angles, and parting lines.

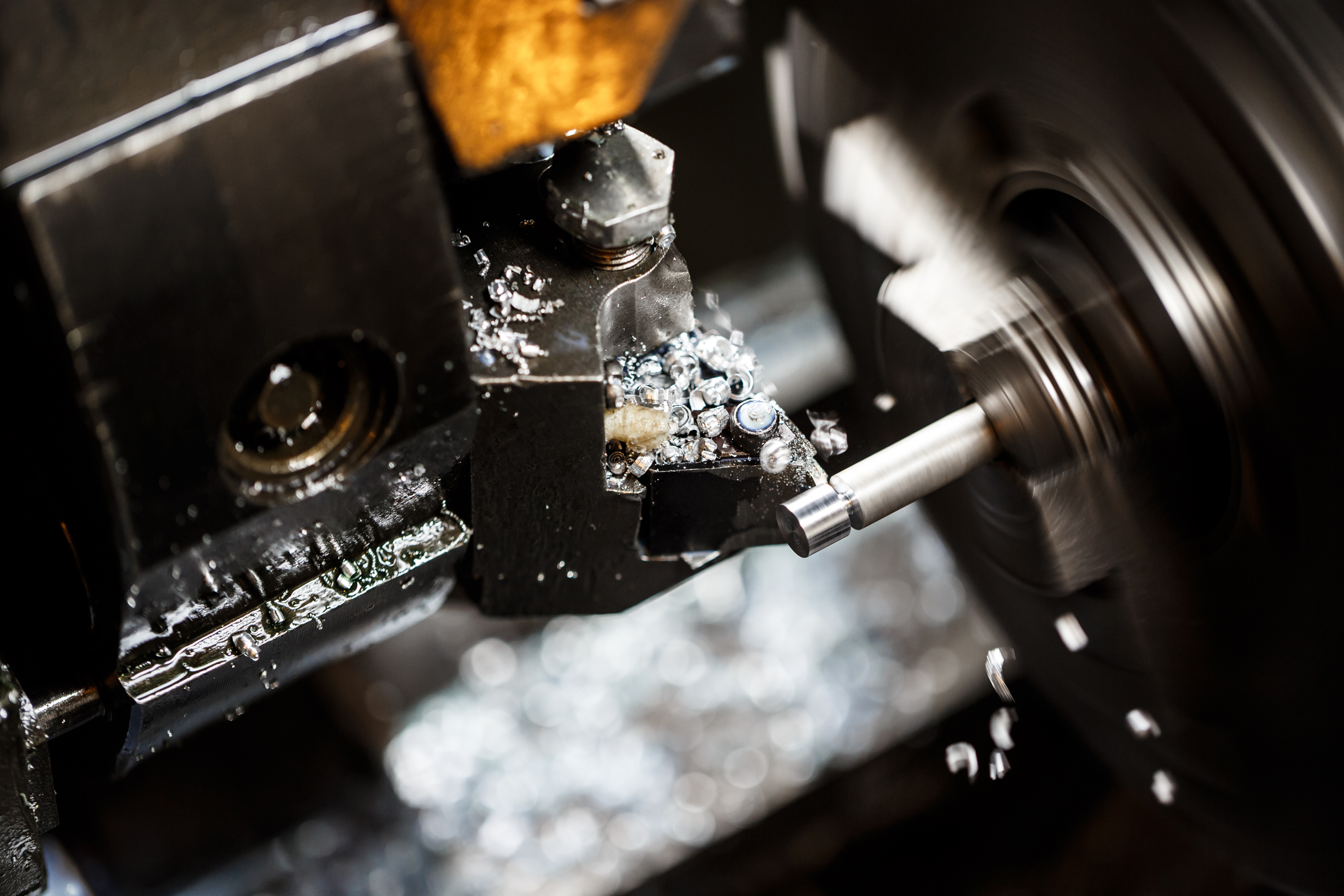

Once the aluminum die casting design is finalized, the die is machined from a steel block using computer numerical control (CNC) machines. The machining process involves cutting and shaping the steel to create the cavities and cores to form the custom aluminum parts.

The die is then heat-treated to harden the steel and improve its durability. After heat treatment, the die is finished to ensure the desired final product’s correct dimensions and surface finish.

Die casting needs a precise design to ensure that the aluminum casting is produced with the desired specifications and can withstand the high pressures and temperatures of the die-casting process.

Molten Aluminum Preparation and Pouring

The preparation and pouring of molten metal are critical steps in the aluminum die-casting process, as the quality and consistency of the aluminum casting depend on the quality and precision of the pouring molten metal process.

The first step in preparing the molten aluminum is to melt pure aluminum in a furnace. The furnace is heated to a temperature above aluminum’s melting point, typically around 700 to 750 degrees Celsius. The aluminum is then added to the furnace and melted down, turning it into a liquid aluminum.

Once the aluminum has melted, casting alloys can be added to the molten metal to modify its properties. Alloying elements can include carbon steel, copper, silicon, magnesium, and zinc. Adding an aluminum alloy can improve cast aluminum’s strength, hardness, and corrosion resistance properties.

After alloying, the molten aluminum must be degassed to remove any trapped gases or impurities that could weaken the aluminum casting.

High-Pressure Injection

The die halves are held together tightly by a hydraulic press to prevent any leakage of the molten aluminum during the high-pressure die-casting process.

Once the die is clamped, the molten aluminum is injected into the die cavity at high pressure. The injection process is controlled by a hydraulic or mechanical system delivering molten aluminum to the die cavity at a specific pressure and speed.

Cooling and Ejection of Aluminum Parts

The cooling process is essential in die-casting processes. It allows the cast aluminum to solidify and take on its final shape. After the molten aluminum has been injected into the die, a cooling system is used to cool the die cast.

The cooling system typically involves circulating water or oil through channels in the die to remove heat from the molten aluminum.

The cooling time required depends on the size and complex shapes of the cast metal but typically takes a few seconds to a few minutes. During this time, the die-cast remains in the die, and the cooling rate is carefully controlled to ensure that the part is cooled uniformly and that any residual stresses are minimized.

Once the cast aluminum has cooled and solidified, the die is opened, and the part is ejected from the die. The ejection process is controlled by a hydraulic or mechanical system that uses ejector pins to push the cast aluminum out of the die.

Surface Finishing for Die Cast Aluminum

After the cast aluminum is ejected from the die, they often require some form of surface finishing to improve its appearance, durability, and functionality. Shot blasting involves firing small metallic or ceramic particles at the surface of the aluminum products at high velocity. This process helps to remove any surface imperfections and create a uniform surface texture.

Anodizing involves immersing the parts in an electrolytic solution and passing an electric current through them. This causes a controlled oxidation of the surface of the parts, resulting in a hard and durable surface layer with excellent corrosion resistance and better casting properties.

Die Casting Machine Used for Aluminum Casting

Die-casting machines are essential equipment in the aluminum die-casting process. They are specialized machines that inject molten metal, usually aluminum, into a mold or die to produce complex and precise parts.

Cold Chamber Machine

Unlike hot chamber machines, cold chamber machines melt the metal in a separate melting pot and then transfer the molten metal into the casting machine. This makes cold chamber machines more suitable for metals with higher melting points and good thermal properties, such as aluminum.

In a cold chamber machine, the liquid aluminum is poured into a shot sleeve or injection cylinder, which is then hydraulically or mechanically operated to force the molten metal into the die mold. The molten metal is injected at high pressure, ensuring it fills the mold and creates a high-quality, dense aluminum part.

Cold chamber machines commonly produce larger parts or parts that require more precise control over the casting process.

Hot Chamber Machine for Other Metals

Hot chamber machines are a type of die-casting machine that is used to produce high-volume, small-to-medium-sized parts. Hot chamber machines are designed to melt the metal directly in the machine using a furnace integrated into the die halves. The furnace is typically filled with a metal, such as zinc or magnesium, with a low melting point.

One of the main advantages of hot chamber machines is their speed and efficiency. The integrated furnace allows for quick and continuous production, particularly when producing high-volume parts. Additionally, the hot chamber process can be automated, increasing efficiency and reducing labor costs.

Aluminum Die Casting Alloy Characteristics

High Strength

The high strength of aluminum die-casting alloys is due to their composition and microstructure. The addition of silicon and copper helps to increase the strength of the alloy, while the addition of magnesium improves corrosion and heat resistance.

This can help to improve the strength and mechanical properties of the part. If a subsequent heat treatment is performed, this can further improve the strength and durability of the material.

Lightweight

One of the critical properties of aluminum die-casting alloys is their lightweight nature. Aluminum is a low-density metal, with a density of approximately one-third that of steel.

The die-casting process itself also contributes to the lightweight properties of aluminum parts. The high-pressure injection process allows for thin walls and complex shapes to be produced, further reducing the final part’s weight.

Corrosion Resistant

Aluminum is highly resistant to corrosion, forming a thin layer of aluminum oxide on its surface when exposed to air. This layer acts as a protective barrier, preventing further corrosion from occurring.

For example, copper is often added to aluminum alloys to improve their strength, but it also helps improve the material’s corrosion resistance. Copper can help form a protective patina on the material’s surface, which helps prevent corrosion.

Similarly, adding magnesium can also improve the corrosion resistance of aluminum die-casting alloys. Magnesium can help improve the material’s strength and durability while providing additional protection against corrosion.

Heat Resistance

The addition of silicon to aluminum alloys can improve their heat resistance properties. Silicon helps to improve the alloy’s strength and hardness, which makes it more resistant to deformation at high temperatures

Another element that can improve the heat resistance of aluminum die-casting alloys is magnesium. Magnesium can help improve the material’s strength and durability while protecting against high temperatures. However, it should be noted that magnesium can also reduce the alloy’s ductility, which can affect its overall performance.

Weldability

Aluminum die-casting alloys generally have good weldability, although the specific properties can vary depending on the composition of the alloy. In general, aluminum alloys have a low melting point and excellent thermal conductivity, which makes them relatively easy to weld.

One important consideration when welding aluminum die-casting alloys is the potential for porosity. To prevent porosity, it is important to properly prepare the surfaces to be welded and use appropriate welding techniques, such as using a filler material to help fill any voids.

Advantages of Die Casting for Cast Aluminum

High Dimensional Stability

The high-pressure injection allows the molten metal to be distributed evenly throughout the die cavity, ensuring that the finished part has a uniform density and dimensional accuracy.

In addition, the high pressure and rapid cooling of the molten metal as it solidifies helps to minimize shrinkage and distortion, further improving the dimensional stability of the finished part.

The high-pressure injection allows the molten metal to be distributed evenly throughout the die cavity, ensuring that the finished part has a uniform density and dimensional accuracy.

The high pressure and rapid cooling of the molten metal as it solidifies helps to minimize shrinkage and distortion, further improving the dimensional stability of the finished part.

Mass Production Efficiency

The die-casting process uses a high-pressure injection system to force molten aluminum into a precisely machined die cavity. Once the mold is filled, the aluminum solidifies quickly, allowing for rapid production rates. This speed and efficiency make the die-casting process ideal for the mass production of aluminum parts.

The dies are typically made from steel or other high-strength materials and are designed to withstand the high pressures and temperatures of the casting process. This allows them to produce large parts without wearing out or degrading quality.

Good Mechanical Properties

The rapid solidification of the molten aluminum in the die cavity creates a fine-grained microstructure with excellent mechanical properties. This microstructure results in parts with high hardness, stiffness, and excellent wear resistance.

Additionally, the ability to use a variety of aluminum alloys in the die-casting process allows manufacturers to tailor the mechanical properties of the aluminum die-casting to its specific requirements.

Surface Finish

One of the primary reasons for this is that the high-pressure injection system used in the process ensures that the molten metal fills the mold, creating a part with minimal or no porosity, shrinkage, or other defects in the aluminum casting.

The dies are typically made of high-strength materials, such as steel, which allows them to maintain their shape and precision for an extended period. This ensures that the surface of the die is smooth and free from defects, which translates into parts with a good surface finish.

Other Casting Processes for Aluminum Alloys

Sand Casting

Sand casting is another commonly used method for producing aluminum castings. Although die casting is preferred for mass production due to its efficiency and consistency, sand casting is still used in certain situations.

One of the primary advantages of sand casting is its versatility. Unlike die casting, which requires complex and expensive tooling, sand casting requires no special tooling. This makes it a more cost-effective option for low-volume production or for producing parts with complex geometries that would be difficult or impossible to produce using die casting.

Because sand casting uses a sand mold that produces parts with a rough surface finish, it is often necessary to machine the parts to achieve the desired surface finish and dimensional accuracy.

Permanent Mold Casting

One of the primary advantages of permanent mold casting is its ability to produce parts with a higher degree of accuracy and consistency than sand casting. The permanent molds are typically made of metal and can be used repeatedly, ensuring that the metal parts produced are consistent in size, shape, and surface finish.

The molds can be designed to accommodate intricate shapes and features, which makes permanent mold casting a good option for producing parts with high levels of detail.

Investment Casting

Investment casting, also known as lost-wax casting, is another method commonly used to produce aluminum castings. While die casting and permanent mold casting are preferred for high-volume production runs, investment casting is often used for producing smaller runs of parts with complex geometries and high levels of detail.