Exploring The Possibilities: Can Sand Casting Cores 3D Printed?

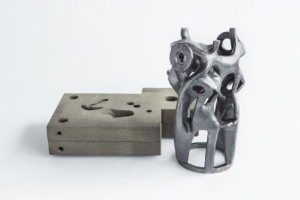

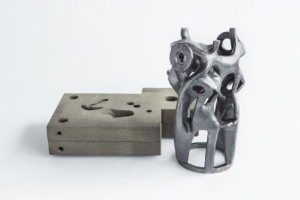

It allows for easy customization of molds and cores. This made the production of complex shapes in small batches or even one-off parts economically possible.

It allows for easy customization of molds and cores. This made the production of complex shapes in small batches or even one-off parts economically possible.

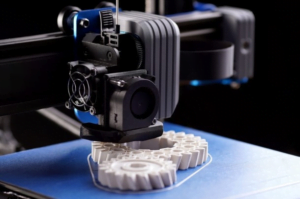

Casting molds may now be made in a way that is both new and more practical thanks to the development of technologies known as additive manufacturing or 3D printing. 3D printed casting molds can be created in a matter of hours, which is important for certain materials that require specific mold properties.

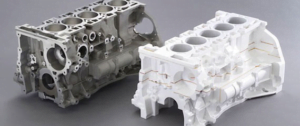

This article will explore the lost foam casting process in detail and discuss its numerous advantages, including design flexibility, cost-effectiveness, and reduced environmental impact.

Kui Tang Foundry is a leading metal casting company located in Weifang, Shandong, China. Established in 2006, we specialize in producing metal castings using high-quality materials for various industries, including engines, automotive, tools, and trains.

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.