Designers aim to keep power high and weight low. Researchers from India and Poland looked into how light materials can help electric motors. Their study, in the journal Energies, shows how to cut motor weight without losing power or performance.

We’ve been studying fluid-cooled motors. We’ve looked at many studies and ideas on this topic. PA6GF30, a special polymer, can cool motors almost as well as aluminum. This means new materials can make Electric Motor Housing, Motor Casing, and Motor Enclosure designs more efficient.

Key Takeaways

- Reducing vehicle weight is crucial for improving efficiency and performance.

- Researchers have explored the use of lightweight materials, such as glass fiber-reinforced polymer composites, in electric motor housings.

- Innovative materials can provide thermal management benefits comparable to traditional aluminum, without sacrificing power efficiency.

- Advancements in Motor Housing Design, Motor Housing Materials, and Motor Housing Cooling are crucial for enhancing the overall efficiency of electric motors.

- The research highlights the potential for optimizing Motor Housing Specifications and Motor Housing Manufacturing processes to improve the efficiency of electric motors.

Benefits of Lightweight Electric Motor Housings

Lightweighting is key to making electric vehicles more efficient and powerful. By making motor housings and other parts lighter, we boost the energy efficiency of these cars. This is done without losing power or reliability. Two main advantages of using Lightweight Electric Motor Housings are:

Reduced Weight for Improved Efficiency

Lighter Motor Casing and Motor Enclosure designs mean less weight for the vehicle. This leads to better fuel economy and less energy use. A 10% weight cut can boost fuel efficiency by 6-8%, making lightweighting vital for green electric vehicles.

Improved Thermal Management

Advanced Motor Housing Design and materials improve electric motor cooling. Good Motor Housing Insulation and Motor Housing Cooling systems keep motors at the right temperature. This ensures they work efficiently without overheating, crucial for high-performance electric cars.

By using lightweight materials and smart cooling, electric car makers can make their vehicles more efficient and eco-friendly. These steps in Motor Housing Repair and Motor Housing Specifications are key for the future of green, high-performance electric cars.

“Lightweighting is integral to improving the sustainability of manufacturing processes because it reduces greenhouse gas emissions, the amount of waste sent to landfills, and the use of finite resources.”

Electric Motor Housing Design Considerations

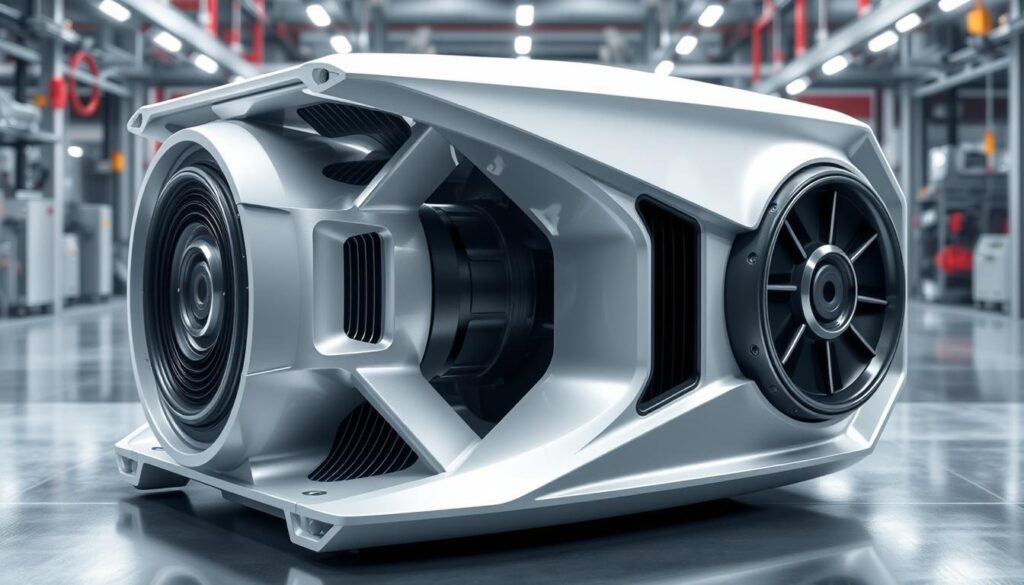

Creating an efficient electric motor housing involves many factors. Choosing the right motor casing materials and adding advanced motor enclosure cooling systems are key. Each part is vital for the motor’s performance and efficiency.

For motor housing design, picking materials that are both light and strong is essential. Researchers look into using carbon fiber and polymer composites instead of metal. These materials can make the motor lighter, boosting its motor housing efficiency.

Insulation and cooling in the motor housing are also crucial. New cooling methods, like water-cooling, help keep the motor cool. This keeps the motor running well and improves its motor housing efficiency.

The way the motor housing is made and repaired is also important. Paying close attention to motor housing specifications and quality control during motor housing manufacturing helps. This ensures the motor lasts longer and works better.

“Optimizing electric motor housing design is a multifaceted challenge that requires a comprehensive approach to material selection, cooling strategies, and manufacturing processes.”

By focusing on these motor housing design aspects, experts can make electric motors more efficient. This leads to more sustainable and energy-saving options.

Innovative Cooling Concepts for Lightweight Housings

Keeping electric motors cool is key to their efficiency and performance. Researchers have found new ways to cool motors, like using water-cooling systems. This helps without losing the lightness of the motor housings.

Water-Cooling Systems

Water-cooling systems help motors run at their best by removing heat. They use water to cool the Electric Motor Housing or Motor Casing. This keeps the motor from overheating.

But, water-cooling systems have their own issues. They can leak and need extra machinery. This adds complexity to Motor Housing Design and Motor Housing Manufacturing. It’s important to pick the right Motor Housing Materials and Motor Housing Insulation for reliability.

Cryogenic cooling with Liquid nitrogen is another method being explored. It uses cold temperatures to make copper more efficient. This can improve the Motor Housing Specifications and boost cooling efficiency.

“Innovative cooling solutions, such as water-cooling systems and cryogenic cooling, are crucial in maintaining the efficiency and performance of electric motors without compromising the benefits of lightweight motor housings.”

The need for more efficient electric motors is growing. Developing good cooling strategies is key for the future of Motor Housing Design and Motor Housing Repair. Manufacturers and engineers must balance performance and reliability in the Motor Housing Specifications.

Conclusion

Lightweight materials and new cooling ideas are key to making electric motors better. These motors power electric cars and other devices. Scientists are looking into materials like fiber-reinforced polymers and aluminum matrix composites.

These materials help make the motors lighter without losing their power. Advanced cooling systems, like water-cooling and cryogenic cooling, also play a big role. They keep the motors at the right temperature, making them work more efficiently.

By focusing on making motors lighter and cooler, we help the environment. This is important for making transportation greener. It’s a step towards a more sustainable future for all of us.

FAQ

What are the key benefits of using lightweight materials in electric motor housings?

Using lightweight materials in electric motor housings has many benefits. It makes the motor lighter, which improves efficiency. It also helps manage heat better with new cooling ideas.

Lighter motors need less energy to move, which saves fuel and is better for the environment.

How do lightweight materials help improve the efficiency of electric motors?

Lightweighting the motor’s outer casing makes the motor lighter. This means it needs less energy to run. So, it works better and more efficiently.

For example, a 10% weight cut in a vehicle can boost fuel economy by 6%-8%.

What innovative cooling concepts are being explored for lightweight electric motor housings?

Scientists are looking into water-cooling systems for electric motors. This keeps the motor cool and efficient without adding weight. They also check out cryogenic cooling with liquid nitrogen.

Cryogenic cooling uses liquid nitrogen to lower copper’s resistance. This means less copper is needed, yet the motor still carries current well.

What materials are being used to create lightweight electric motor housings?

Researchers are testing different materials for motor parts. They look at carbon fiber, polymer composites, and aluminum composites. These can replace heavy metal parts, making the motor lighter and more efficient.

How do design considerations impact the performance of lightweight electric motor housings?

The design of motor housings is key for their performance. It includes the materials used, cooling systems, and how parts are arranged. Scientists are working on new designs and materials to make motors more sustainable.