At KT-Foundry, we pride ourselves on our expertise in providing carbon steel casting solutions for infrastructure projects. Carbon steel casting is a critical component in construction and transportation, offering exceptional strength, durability, and cost-effectiveness. Our company specializes in delivering customized carbon steel casting solutions for diverse infrastructure needs, ensuring the highest quality and reliability.

Key Takeaways:

- Carbon steel casting is an essential part of infrastructure projects, offering strength, durability, and cost-effectiveness.

- KT-Foundry is a leading provider of customized carbon steel casting solutions for construction and transportation needs.

- Our expertise and quality assurance processes ensure the delivery of high-quality and reliable carbon steel casting products.

- Carbon steel casting is utilized in manufacturing bridge components and railway components.

- The future of carbon steel casting in infrastructure projects is bright, with advancements in technology, materials, and design shaping the industry.

Understanding Carbon Steel Casting

At KT-Foundry, we specialize in providing carbon steel casting solutions for construction and transportation applications. Carbon steel casting is a manufacturing process that involves pouring molten carbon steel into a hollow cast or mold, where it solidifies and takes on the shape of the cast or mold.

Carbon steel is composed primarily of iron and carbon, with trace amounts of other elements like manganese, sulfur, and phosphorus. The carbon content of carbon steel can range from 0.05% to 2.0%, with higher carbon content resulting in increased strength and hardness.

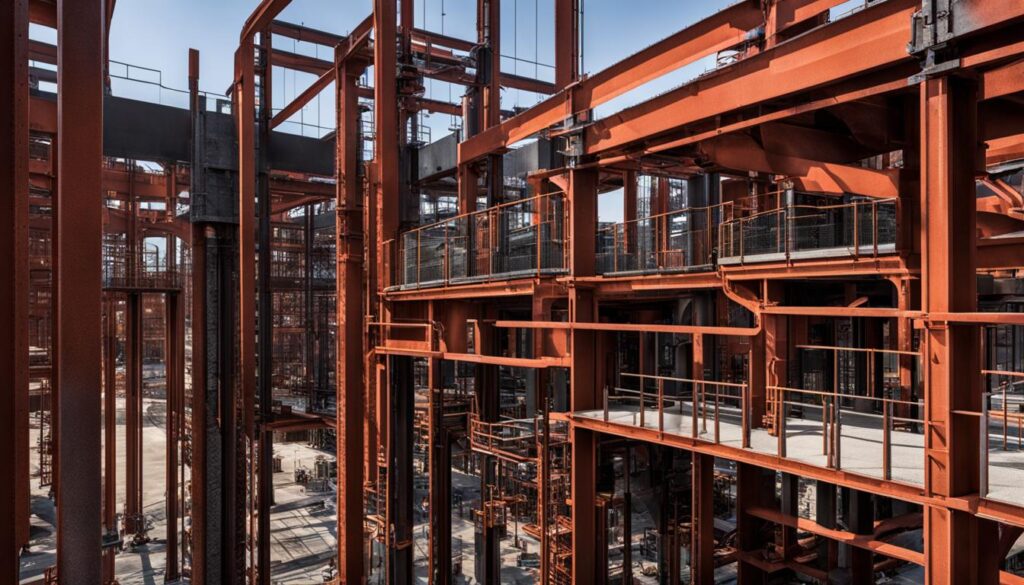

Carbon steel casting is renowned for its exceptional strength, durability, and cost-effectiveness, making it a preferred material for a wide range of construction and transportation projects. Its strength and durability make it ideal for use in high-stress applications like bridges, railway tracks, and heavy machinery components.

The manufacturing process for carbon steel casting involves melting down raw materials like iron ore, coke, and limestone in a blast furnace. The resulting molten steel is then poured into molds or casts, where it solidifies and takes on the desired shape. This process is highly versatile, allowing for the creation of complex shapes and designs that would be difficult or impossible to achieve with other manufacturing methods.

Advantages of Carbon Steel Casting in Construction and Transportation

Carbon steel casting offers numerous advantages over other materials in construction and transportation applications.

- Exceptional strength and durability: Carbon steel is renowned for its strength and durability, making it ideal for use in demanding applications like construction and transportation. Its high tensile strength, impact resistance, and shock absorption properties make it resistant to failure and ensure long-term reliability.

- Corrosion resistance: Carbon steel is highly resistant to corrosion, rust, and other forms of degradation. This makes it ideal for use in harsh environments where exposure to moisture, salt, and other corrosive elements is common.

- Cost-effectiveness: Carbon steel casting is an affordable manufacturing process that offers excellent value for money. Its low production costs and high availability make it a cost-effective choice for a wide range of construction and transportation projects.

Our expertise in carbon steel casting allows us to provide customized solutions that meet the specific needs of our clients. We work closely with our clients to design and manufacture carbon steel casting components that are tailored to their unique requirements, ensuring maximum performance and longevity.

We are committed to providing our clients with the highest quality carbon steel casting products for construction and transportation applications. Our state-of-the-art manufacturing facilities, rigorous quality control processes, and experienced team of technicians and engineers ensure that every product we produce meets the highest standards of quality and reliability.

Applications of Carbon Steel Casting in Infrastructure

Carbon steel casting has a wide range of applications in infrastructure projects, including the manufacturing of bridge and railway components.

Bridge Components

Carbon steel casting is often used to manufacture various components of bridges such as girders, piers, and abutments. These components require high strength and durability to withstand the weight and constant use of vehicular and pedestrian traffic. Carbon steel casting provides this strength and durability while also being cost-effective.

| Component | Material | Advantages of Carbon Steel Casting |

|---|---|---|

| Girders | Carbon steel | High strength and durability, resistant to corrosion and fatigue |

| Piers and abutments | Carbon steel | Excellent tensile strength, ductility, and impact resistance |

In addition to their high performance, carbon steel casting bridge components are also customizable, allowing for flexibility in design and construction projects.

Railway Components

Carbon steel casting is also extensively used in the manufacturing of railway components, including tracks, couplers, and bogies. These components require high strength and durability to endure the heavy load of trains and the constant stress of travel. Carbon steel casting provides these characteristics while also being cost-effective.

| Component | Material | Advantages of Carbon Steel Casting |

|---|---|---|

| Tracks | Carbon steel | Highly resistant to wear and tear, fatigue, and thermal expansion |

| Couplers and bogies | Carbon steel | Excellent strength, ductility, and impact resistance, and highly resistant to corrosion |

Carbon steel casting railway components are customizable and can be manufactured in large quantities, making it an ideal choice for railway construction and maintenance needs.

Advantages of Carbon Steel Casting in Infrastructure

Carbon steel casting offers numerous advantages in infrastructure projects, making it a popular choice for construction and transportation applications. At KT-Foundry, we specialize in providing customized carbon steel casting solutions for the unique needs of our clients, ensuring exceptional strength, durability, and cost-effectiveness.

Exceptional strength: Carbon steel casting is renowned for its exceptional strength, making it a top choice for demanding infrastructure applications. Its high tensile strength and resistance to wear and tear make it ideal for manufacturing components such as bridge girders, railway tracks, and machinery parts.

Corrosion resistance: Carbon steel casting is highly resistant to corrosion, ensuring longevity and reliability in harsh environments. This makes it a top choice for infrastructure projects located in areas with high exposure to corrosion, such as bridges and other transportation structures.

Cost-effectiveness: Carbon steel casting is a cost-effective solution for infrastructure projects, providing superior performance and durability at a lower cost than other materials. Its versatility and adaptability make it a preferred choice for a range of applications, including construction, transportation, and machinery.

Comparative Analysis of Materials in Infrastructure

| Material | Strength | Corrosion Resistance | Cost-effectiveness |

|---|---|---|---|

| Carbon Steel Casting | High | High | Low |

| Stainless Steel | High | Very High | High |

| Aluminum | Low to Medium | Low to Medium | Low to Medium |

As shown in the table above, carbon steel casting offers a balance of strength, corrosion resistance, and cost-effectiveness that is unmatched by other materials. Its versatility and adaptability make it an ideal choice for a wide range of infrastructure applications, ensuring reliable and long-lasting performance.

At KT-Foundry, we are committed to delivering high-quality carbon steel casting solutions for infrastructure projects. Our expertise in the field and adherence to strict quality assurance standards enable us to provide customized solutions that meet the unique needs of our clients. Contact us today to learn more about our services and how we can support your infrastructure project.

Quality Assurance in Carbon Steel Casting for Infrastructure

At KT-Foundry, quality assurance is key to our carbon steel casting process for infrastructure projects. We understand that every component manufactured must meet strict standards to ensure its strength, durability, and safety. We employ a comprehensive quality control process to ensure that each product is manufactured to perfection.

Testing Process

Our testing process includes checking for dimensional accuracy, surface finish, and mechanical properties. We use advanced equipment like X-ray machines, spectrometers, and ultrasonic testing machines to ensure that each component meets the highest quality standards.

Our Commitment to Quality

Our commitment to quality is evident in our products and our satisfied clients. We understand the importance of delivering high-quality, reliable products that meet the unique needs of each project. Our team of engineers and technicians works tirelessly to ensure that each and every component we manufacture is of the highest quality.

Trust us to deliver high-quality, durable carbon steel casting products for your infrastructure projects. Contact us today for more information on our range of carbon steel casting solutions.

Future Trends and Innovations in Carbon Steel Casting for Infrastructure

At KT-Foundry, we believe that innovation is key to maintaining a competitive advantage in the carbon steel casting industry. As infrastructure projects become more complex and demanding, it is essential to stay ahead of the curve by exploring new technologies and materials. Here are some of the most exciting trends and innovations currently shaping the future of carbon steel casting in infrastructure:

1. Digital Manufacturing

Digital manufacturing, also known as Industry 4.0, is a groundbreaking approach to manufacturing that utilizes advanced technology to improve efficiency, reduce waste, and increase productivity. Through the use of sensors, automation, and data analytics, digital manufacturing can optimize the entire production process, from design to delivery. In carbon steel casting, digital manufacturing can help us create more precise and accurate molds, reduce lead times, and improve the overall quality of our products.

2. Additive Manufacturing

Additive manufacturing, also called 3D printing, is revolutionizing the manufacturing industry by enabling the production of complex and customized parts with unprecedented precision and speed. In carbon steel casting, additive manufacturing can be used to create intricate and lightweight structures that are difficult or impossible to produce using traditional casting methods. This technology can also reduce waste, lower costs, and improve sustainability by using only the necessary amount of materials.

3. Advanced Materials

The development of advanced materials is opening up new possibilities for carbon steel casting in infrastructure. For example, the use of high-strength alloys can enhance the durability and load-bearing capacity of bridges and other structures. Additionally, the incorporation of smart materials, such as shape-memory alloys or self-healing materials, can improve the resilience and safety of infrastructure components.

4. Sustainable Practices

Sustainability is an increasingly important concern for infrastructure projects, and carbon steel casting is no exception. By adopting more sustainable practices, we can reduce our environmental impact and improve our social responsibility. For instance, using recycled steel scrap can lower energy consumption and greenhouse gas emissions, while optimizing our manufacturing processes can minimize waste and water usage. We are committed to incorporating sustainable practices into our operations, and we believe that this focus will only grow in the future.

By embracing these and other trends and innovations, we are confident that carbon steel casting will continue to play a pivotal role in the infrastructure of tomorrow.

Conclusion

At KT-Foundry, we pride ourselves on our expertise in carbon steel casting for infrastructure projects. Our commitment to quality assurance and adherence to industry standards ensures that our customers receive high-quality and reliable carbon steel casting products for diverse infrastructure needs.

As discussed in this article, carbon steel casting plays a significant role in construction and transportation sectors. Its strength, durability, and cost-effectiveness make it an ideal choice for demanding applications in infrastructure. Our customized carbon steel casting solutions have been used in notable projects such as bridge components like girders, piers, and abutments, as well as railway components like tracks, couplers, and bogies.

Looking towards the future, we are excited about the ongoing innovations and advancements in carbon steel casting for infrastructure. New technologies, materials, and designs will continue to shape the future of carbon steel casting, ensuring even greater efficiency, sustainability, and performance. As a company, we remain committed to staying at the forefront of these innovations to deliver the best possible solutions for our customers.

Overall, we believe that carbon steel casting will continue to play a crucial role in building and maintaining infrastructure in the years to come. As a leading provider of carbon steel casting solutions, we are ready to meet the diverse needs of infrastructure projects, from manufacturing to testing to delivery. Contact us today to learn more about our services and capabilities.

FAQ

What is carbon steel casting?

Carbon steel casting is a manufacturing process where molten carbon steel is poured into a mold and allowed to solidify into a desired shape. It is commonly used in infrastructure projects for its strength, durability, and cost-effectiveness.

What are the advantages of using carbon steel casting in infrastructure?

Carbon steel casting offers exceptional strength, corrosion resistance, and cost-effectiveness, making it an ideal choice for demanding applications in construction and transportation. It provides the necessary durability to withstand heavy loads, extreme weather conditions, and long-term exposure.

What are the specific applications of carbon steel casting in infrastructure?

Carbon steel casting is widely used in manufacturing bridge components such as girders, piers, and abutments. It is also utilized in the production of railway components including tracks, couplers, and bogies. These applications require the strength and reliability offered by carbon steel casting.

What is the quality assurance process in carbon steel casting for infrastructure?

Quality assurance in carbon steel casting for infrastructure involves rigorous testing processes, certifications, and adherence to industry standards. KT-Foundry ensures the delivery of high-quality and reliable carbon steel casting products by maintaining strict quality control measures and continuously improving our manufacturing capabilities.

Can you provide any case studies of successful carbon steel casting projects in infrastructure?

Certainly! We have numerous case studies showcasing our successful carbon steel casting projects in infrastructure. These projects demonstrate our expertise and capability in delivering customized solutions for diverse infrastructure needs. Please contact us for more information and specific examples.

What are the future trends and innovations in carbon steel casting for infrastructure?

The future of carbon steel casting in infrastructure is shaped by advancements in technology, materials, and design. Innovations such as improved casting processes, advanced alloy compositions, and enhanced sustainability measures are being explored to further enhance the efficiency and performance of carbon steel casting.