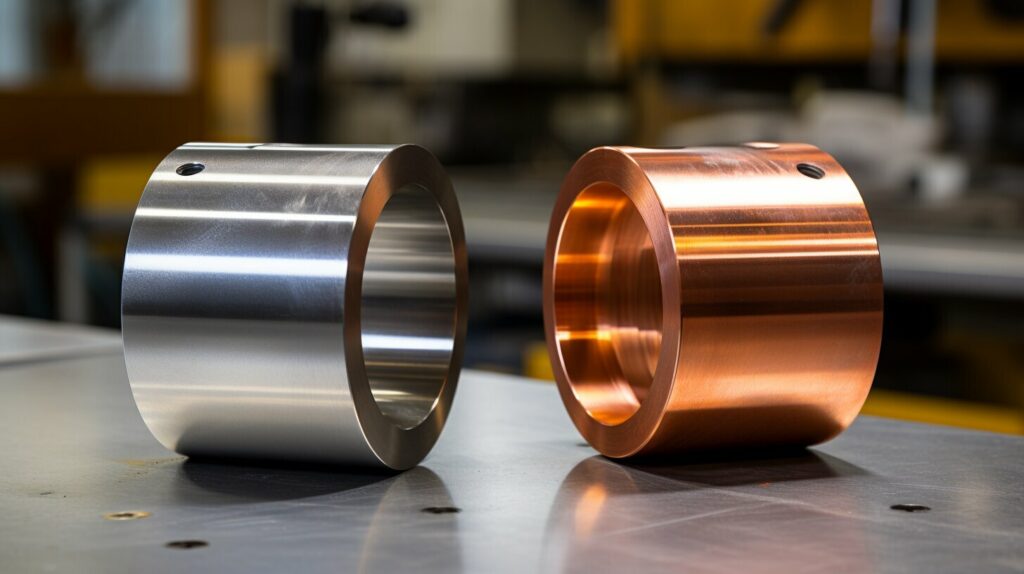

When it comes to stainless steel casting, selecting the appropriate alloy is crucial for achieving the desired properties and performance. The two main types of alloys used in casting are Austenitic and Martensitic. Both have their unique characteristics and advantages, but choosing the right one depends on several factors.

Austenitic stainless steels are popular for their excellent corrosion resistance and high ductility. They are also known for their ability to withstand high temperatures, making them ideal for applications where heat resistance is critical. Martensitic stainless steels, on the other hand, offer superior hardness and strength, as well as good wear and corrosion resistance.

When selecting an alloy for stainless steel casting, it is essential to consider the specific requirements of the application, such as the environment, the desired mechanical properties, and the casting grade. Understanding the differences between Austenitic and Martensitic stainless steels is crucial for making an informed decision.

Key Takeaways:

- Choosing the right alloy is crucial for successful stainless steel casting.

- Austenitic stainless steels offer excellent corrosion resistance and high ductility.

- Martensitic stainless steels provide superior hardness, strength, and wear resistance.

- The selection of the appropriate alloy depends on the specific requirements of the application, including the environment, the desired mechanical properties, and the casting grade.

- Understanding the differences between Austenitic and Martensitic stainless steels is essential for making an informed decision.

Understanding Austenitic Stainless Steels for Casting

When it comes to stainless steel casting, Austenitic stainless steel is a popular choice for its excellent corrosion resistance and durability. Its unique microstructure also makes it highly resistant to stress corrosion cracking and crevice corrosion, making it ideal for harsh or corrosive environments.

Austenitic stainless steel castings are available in a range of grades, each with its own unique properties. For example, duplex stainless steel castings are a combination of both Austenitic and Ferritic stainless steels, offering enhanced strength and corrosion resistance. Other Austenitic stainless steel grades, like 304 and 316, are also commonly used for their excellent corrosion resistance and ease of fabrication.

In addition to its corrosion resistance, Austenitic stainless steel is also highly weldable, making it a versatile choice for a range of applications. It also has excellent formability and can be easily worked into intricate shapes or designs.

Overall, Austenitic stainless steel castings are a reliable choice for industries such as food and beverage, chemical processing, and marine applications due to their superior corrosion resistance and durability.

Duplex Stainless Steel Castings

Duplex stainless steel castings contain a mixture of both Austenitic and Ferritic stainless steels, offering improved strength and corrosion resistance over both materials individually. This makes them an ideal choice for applications where high strength and corrosion resistance are required, such as in oil and gas or chemical processing equipment.

They are also a cost-effective alternative to more expensive materials like nickel alloys, without sacrificing on performance or durability.

Other Stainless Steel Castings

While Austenitic stainless steel and duplex stainless steel are popular choices for casting, there are also other variations available for specific applications. Ferritic stainless steel castings, for example, offer excellent thermal conductivity and are often used in high-temperature applications like furnace parts or automotive exhaust systems.

Martensitic stainless steel castings are also an option, though they are less commonly used due to their lower corrosion resistance compared to Austenitic and duplex stainless steels.

Overall, selecting the appropriate stainless steel grade for your casting application will depend on a range of factors, including the specific environment, required mechanical properties, and manufacturing process.

- Austenitic stainless steel castings: corrosion-resistant, highly weldable, and versatile

- Duplex stainless steel castings: a combination of Austenitic and Ferritic stainless steels for enhanced strength and corrosion resistance

- Other stainless steel castings: variations like Ferritic and Martensitic stainless steels offer specific advantages for certain applications

Consider all your options carefully and consult with a professional in the field to ensure optimal performance and longevity of your stainless steel castings.

Examining the Characteristics of Martensitic Stainless Steel in Casting

In the world of stainless steel casting, Martensitic stainless steel is a popular choice due to its strength and durability. Martensitic stainless steel contains more carbon than Austenitic steel, which gives it a higher hardness and strength but lower corrosion resistance. This alloy is commonly used in applications where high strength and hardness are required, such as oil and gas, chemical processing equipment, and food processing equipment.

Compared to Austenitic steel, Martensitic stainless steel has a different microstructure, with a body-centered tetragonal crystal lattice. This results in a material that is less ductile but more brittle and strong. Ferritic stainless steel castings, on the other hand, have a body-centered cubic crystal lattice, which makes them even less ductile than Martensitic steel.

One of the benefits of Martensitic stainless steel is its ability to be heat treated to obtain even greater strength and hardness. Unlike Austenitic steel, which cannot be hardened by heat treatment, Martensitic steel can be heat treated to increase its strength and hardness.

| Stainless Steel Casting Type | Microstructure |

|---|---|

| Austenitic Stainless Steel | Austenitic |

| Martensitic Stainless Steel | Body-centered tetragonal |

| Ferritic Stainless Steel | Body-centered cubic |

In conclusion, Martensitic stainless steel is a strong and durable alloy commonly used in various industries. Its strength and hardness make it an excellent choice for applications where high strength is required. However, its lower corrosion resistance and brittleness should be taken into consideration when selecting the appropriate alloy for stainless steel casting.

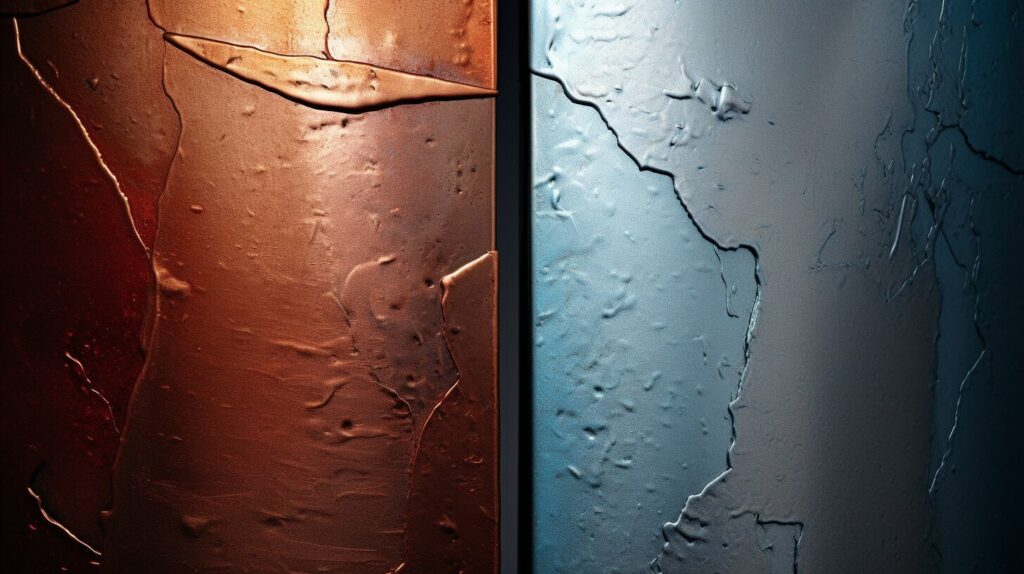

Comparing Corrosion Resistance in Austenitic and Martensitic Stainless Steels

One of the most critical factors to consider when choosing the right alloy for stainless steel casting is corrosion resistance. Both Austenitic and Martensitic stainless steels offer varying degrees of corrosion resistance, making them suitable for different environments and applications.

The Austenitic microstructure, common in stainless grades such as 304 and 316, provides excellent corrosion resistance in a wide range of environments. These alloys are highly resistant to corrosion due to their high levels of chromium and nickel, making them ideal for use in harsh industrial settings, food processing equipment, and medical applications.

On the other hand, Martensitic stainless steels, such as 410, have lower levels of nickel and higher levels of carbon, making them less resistant to corrosion than Austenitic steels. These alloys are more suitable for applications that require hardness and wear resistance, such as cutting tools and turbine blades.

It is essential to note that both Austenitic and Martensitic stainless steels also come in duplex and ferritic variations, which have unique strengths and limitations in terms of corrosion resistance. However, in general, Austenitic stainless steels offer the most corrosion resistance, while Martensitic stainless steels offer less, although still adequate, resistance.

| Stainless Steel Grade | Corrosion Resistance |

|---|---|

| Austenitic Microstructure (304, 316) | Excellent corrosion resistance in a wide range of environments |

| Martensitic (410) | Adequate corrosion resistance, suitable for applications that require hardness and wear resistance |

In conclusion, when selecting an alloy for stainless steel casting, considering the level of corrosion resistance required for the application is crucial. Austenitic stainless steels are the most corrosion-resistant, while Martensitic stainless steels offer adequate, but lesser, resistance. By understanding the corrosion-resistant properties of each alloy, you can make an informed decision for your specific casting needs, ensuring optimal performance and durability.

Mechanical Properties and Heat Treatment of Stainless Steel Castings

When it comes to stainless steel castings, mechanical properties and heat treatment are essential factors to consider. The right heat treatment can significantly improve the strength and hardness of stainless steel castings. This section will focus on the mechanical properties and heat treatment options for various stainless steel grades, including Austenitic, Ferritic, and Martensitic stainless steel.

Weldable Stainless Steels

Austenitic stainless steels are the most weldable stainless steels. They are highly resistant to cracking during welding, making them ideal for applications that require weldability. Duplex stainless steels are also weldable, but may require special precautions during welding to prevent cracking. Ferritic stainless steels, on the other hand, have poor weldability and may require preheating or post-weld heat treatment to prevent cracking. Martensitic stainless steels are also known for their poor weldability and may require preheating or post-weld heat treatment to prevent cracking.

Heat Treated Austenitic Steels

Austenitic stainless steels are known for their excellent corrosion resistance and are often used in harsh environments. Heat treatment can increase their strength and hardness, improving their mechanical properties even further. Austenitic grades such as 304 and 316 are commonly heat treated to increase their strength and hardness. Heat treatment can also improve the toughness and ductility of austenitic stainless steel castings.

Duplex Stainless Steels

Duplex stainless steels are known for their excellent corrosion resistance and high strength. They are often used in the oil and gas industry and chemical processing equipment applications. Duplex stainless steels can be heat treated to improve their mechanical properties, but this can also impact their corrosion resistance. Careful consideration should be given to the specific application requirements when selecting and heat treating duplex stainless steel castings.

Ferritic Stainless Steels

Ferritic stainless steels are known for their low strength and poor weldability. However, they are highly resistant to stress corrosion cracking and are often used in applications such as automotive exhaust systems and heat exchangers. Heat treatment can improve the strength and hardness of ferritic stainless steel castings, but this can also impact their corrosion resistance. Careful consideration should be given to the specific application requirements when selecting and heat treating ferritic stainless steel castings.

Martensitic Stainless Steels

Martensitic stainless steels are known for their high strength and hardness. They are often used in applications that require high wear resistance, such as cutlery and surgical instruments. Martensitic stainless steels can be heat treated to improve their mechanical properties, but this can also impact their corrosion resistance. Careful consideration should be given to the specific application requirements when selecting and heat treating martensitic stainless steel castings.

In summary, the mechanical properties and heat treatment options for stainless steel castings vary depending on the specific grade of stainless steel. Austenitic stainless steels are the most weldable and are often heat treated to improve their properties. Duplex stainless steels are also weldable and can be heat treated, but careful consideration should be given to their corrosion resistance. Ferritic stainless steels have poor weldability but are highly resistant to stress corrosion cracking. Martensitic stainless steels are known for their high strength and hardness, but their weldability is poor.

Conclusion

In summary, selecting the appropriate alloy is critical for successful stainless steel casting. As we have discussed, Austenitic and Martensitic alloys have different characteristics that must be considered when making this decision. Austenitic stainless steels are popular due to their high corrosion resistance, making them ideal for use in harsh environments. Additionally, they offer excellent weldability and are available in various grades, including duplex stainless steel castings. On the other hand, Martensitic stainless steels are known for their high strength and hardness, making them suitable for applications in the oil and gas, chemical processing equipment, and food processing equipment industries. When it comes to corrosion resistance, Austenitic stainless steel has the edge, particularly in harsh environments, but it’s essential to consider the specific application and environment when selecting the appropriate alloy. Furthermore, the mechanical properties and heat treatment of stainless steel play a significant role in their performance. It’s necessary to pay attention to the various grades and heat treatment options available to ensure optimal tensile strength. In conclusion, selecting the appropriate alloy, considering factors like corrosion resistance, mechanical properties, and heat treatment, is essential for successful stainless steel casting. We hope that this article has provided valuable insights into the world of stainless steel casting and helps inform future decisions for your specific casting needs.

FAQ

Q: What are the main factors to consider when choosing the right alloy for stainless steel casting?

A: The main factors to consider include corrosion resistance, casting grade, and mechanical properties.

Q: What is the difference between Austenitic and Martensitic stainless steel alloys?

A: Austenitic stainless steels have a face-centered cubic crystal structure and offer excellent corrosion resistance, while Martensitic stainless steels have a body-centered tetragonal crystal structure and are known for their high strength and hardness.

Q: Which industries commonly use Austenitic stainless steel castings?

A: Austenitic stainless steel castings are commonly used in industries such as food processing, chemical processing, and oil and gas.

Q: Can Martensitic stainless steel be welded?

A: Yes, Martensitic stainless steel can be welded, although it may require preheating and post-weld heat treatment to prevent cracking and preserve the desired properties.

Q: How does heat treatment affect the properties of stainless steel castings?

A: Heat treatment can modify the mechanical properties of stainless steel castings, improving their strength, hardness, and dimensional stability.

Q: Which stainless steel grade offers the best corrosion resistance?

A: Austenitic stainless steel grades, especially those with a higher nickel content, typically offer the best corrosion resistance among stainless steels.

Q: What are the limitations of Martensitic stainless steel in casting?

A: Martensitic stainless steel is more prone to cracking during casting due to its higher carbon content and lower ductility compared to Austenitic stainless steel.

Q: Can Austenitic and Martensitic stainless steels be used together in a casting?

A: Yes, it is possible to use Austenitic and Martensitic stainless steels together in a casting, depending on the specific requirements of the application.

Q: Are stainless steel castings suitable for high-temperature applications?

A: Yes, certain stainless steel grades, such as Austenitic and Duplex stainless steels, can withstand high temperatures and are commonly used in applications where heat resistance is required.

Q: What is the tensile strength of stainless steel castings?

A: The tensile strength of stainless steel castings can vary depending on the specific alloy and heat treatment, but it is generally in the range of 500-800 MPa.

At KT-Foundry, we grasp the significance of precision and meticulousness in crafting tailored castings for our valued clients. Our team comprises seasoned engineers and skilled technicians who leverage cutting-edge technology and advanced techniques to ensure that each casting aligns with your exact specifications.