At KT-Foundry, we are proud to offer a premium welding table top designed specifically for Australian professionals. This durable, precision-engineered surface is built to last, enhancing your welding projects with its sturdy construction and heat-resistant properties. Whether you’re a seasoned welder or just starting, our welding table top provides the stability and reliability you need for your professional-grade work.

Key Takeaways

- Durable, precision-engineered welding table top designed for Australian professionals

- Sturdy construction and heat-resistant properties for enhanced reliability

- Suitable for seasoned welders and beginners alike

- Offers the stability and reliability needed for professional-grade welding projects

- Manufactured by the reputable KT-Foundry brand

Choosing the Ideal Welding Table Top: A Comprehensive Guide

Welding demands precision, skill, and top-tier equipment for unmatched results. While many professionals prioritize advanced welding machines and protective gear, an often undervalued yet vital tool is the welding table top. Choosing the right welding table top can profoundly influence the quality, safety, and speed of your welding tasks. For welding enthusiasts and metal fabrication experts, the ideal welding table top can lead to substantial time and cost savings during setups.

Understanding the Importance of a Reliable Welding Table Top

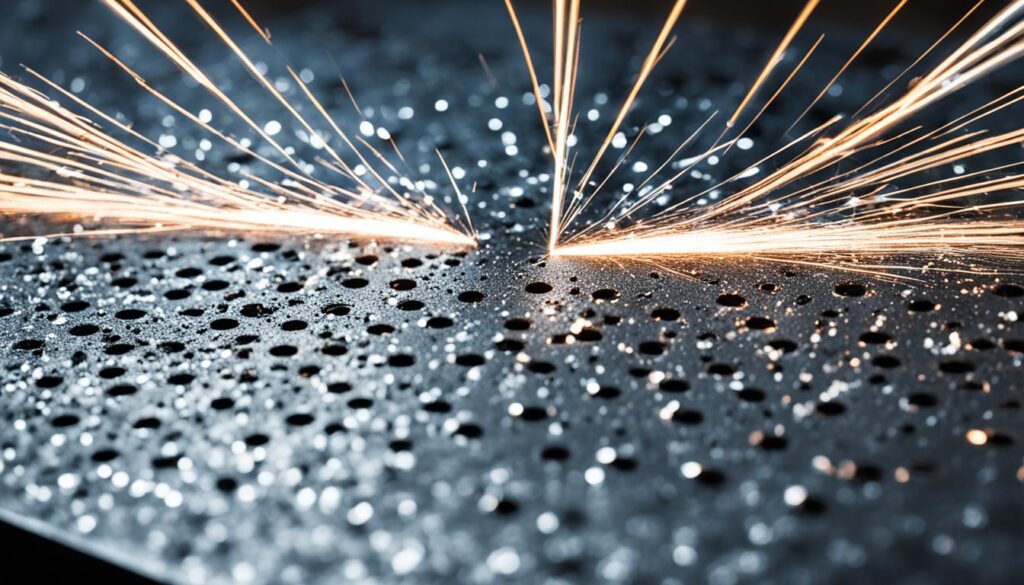

A sturdy, well-designed welding table top serves as the foundation for your welding projects. It provides a stable and level surface to securely hold your workpieces in place, ensuring accurate and consistent welds. The table top’s material, size, and construction can also impact heat distribution, sparks, and slag management, contributing to a safer and more efficient welding environment.

Factors to Consider When Selecting a Welding Table Top

When choosing a welding table top, there are several key factors to consider:

- Size and Dimensions: Measure your available workspace and choose a welding table top that fits comfortably, allowing enough room to maneuver your projects.

- Material and Construction: Opt for durable materials like steel or cast iron that can withstand high heat, sparks, and heavy-duty use.

- Weight Capacity: Ensure the table top can support the weight of your workpieces and any additional equipment or accessories.

- Stability and Leveling: Look for a table top with a sturdy frame and adjustable legs to maintain a level surface.

- Portability: If you need to move your welding station, consider a table top with casters or a lightweight design.

By carefully evaluating these factors, you can find the perfect welding table top that aligns with your specific welding projects and workshop requirements.

The welding table top Difference: Materials and Construction

When it comes to the world of metal fabrication and welding, the choice of table top material can make all the difference. Two of the most popular options are steel welding table tops and cast iron welding table tops, each offering unique benefits that cater to the diverse needs of professional welders and metal workers.

Steel Welding Table Tops: Durable and Heat-Resistant

Steel welding table tops are renowned for their exceptional durability and heat resistance, making them a go-to choice for heavy-duty welding tasks. The robust construction of steel welding table ensures the table top can withstand the intense heat, sparks, and occasional molten metal generated during the welding process, maintaining a flat and level steel work table surface throughout your projects.

Cast Iron Welding Table Tops: Unmatched Stability

Cast iron welding table tops offer unmatched stability, a crucial feature for precision welding. The high-density, rigid construction of cast iron provides a solid foundation that minimizes vibrations and flexing, allowing you to execute welds with exceptional accuracy. This stability is particularly important for intricate, detailed, or large-scale welding projects, where maintaining the workpiece’s alignment is paramount.

“The choice of metal fabrication table material can make all the difference in the quality and precision of your welding projects.”

Whether you opt for a steel welding table top or a cast iron welding table top, the material and construction of your welding table can have a significant impact on the outcome of your work. By considering the unique characteristics of each option, you can ensure that your steel work table is well-equipped to handle the demands of your professional metal fabrication endeavors.

Conclusion

Selecting the right welding table top is a vital decision that can significantly impact the quality, efficiency, and safety of your welding projects. By understanding the importance of a reliable welding table top and the key factors to consider, we can choose a solution that not only meets but exceeds our expectations. Whether we prefer the durability of steel or the unparalleled stability of cast iron, KT-Foundry’s premium welding table tops are designed to elevate our welding experience and help us achieve professional-grade results.

Our choice of welding table top can make all the difference in the success of our welding projects. By investing in a high-quality, well-constructed table top, we can ensure consistent, accurate, and safe welding outcomes, ultimately contributing to the overall success of our professional endeavors. The team at KT-Foundry is dedicated to providing the best possible welding solutions to meet our needs and help us reach new heights in our craft.

As we embark on our next welding project, let’s remember the importance of a reliable welding table top. With the guidance provided in this comprehensive guide and the exceptional products offered by KT-Foundry, we can make an informed decision that will enhance our welding capabilities and lead to exceptional results time and time again.

FAQ

What makes KT-Foundry’s welding table top a premium choice for Australian professionals?

Our welding table top is designed with durability and precision in mind, featuring a sturdy construction and heat-resistant properties that enhance the quality and efficiency of your welding projects. Whether you’re a seasoned welder or just starting, our table top provides the stability and reliability you need for professional-grade work.

Why is the choice of a welding table top so important for welding professionals?

Welding demands precision, skill, and top-tier equipment for unmatched results. The welding table top is a vital, yet often undervalued, tool that can profoundly influence the quality, safety, and speed of your welding tasks. Choosing the right welding table top can lead to substantial time and cost savings during setups.

What key factors should I consider when selecting a welding table top?

When choosing a welding table top, you should consider factors such as size and dimensions, material and construction, weight capacity, stability, and portability. Understanding these elements will help you find the perfect welding table top that aligns with your specific welding projects and workshop requirements.

What are the advantages of steel welding table tops?

Steel welding table tops are renowned for their exceptional durability and heat resistance, making them a popular choice for heavy-duty welding tasks. The robust construction of steel ensures the table top can withstand the intense heat, sparks, and occasional molten metal generated during the welding process, maintaining a flat and level work surface throughout your projects.

Why are cast iron welding table tops known for their stability?

Cast iron welding table tops offer unmatched stability, a crucial feature for precision welding. The high-density, rigid construction of cast iron provides a solid foundation that minimizes vibrations and flexing, allowing you to execute welds with exceptional accuracy. This stability is particularly important for intricate, detailed, or large-scale welding projects, where maintaining the workpiece’s alignment is paramount.