At KT-Foundry, we specialize in producing top-quality engine components utilizing gray iron castings—a material fundamental to the automotive engineering and industrial machinery manufacturing industries. Gray iron, characterized by its graphite microstructure, provides our components with essential properties such as high compressive strength, exceptional wear resistance, and thermal conductivity. These characteristics make gray iron an invaluable material for parts like engine blocks and cylinder heads that must endure intense heat and stress. Our focus on leveraging the strengths of gray iron casting ensures that we deliver engine components that meet the highest standards of performance and durability.

Key Takeaways

- Gray iron castings are essential for producing high-quality engine components.

- KT-Foundry specializes in gray iron castings for automotive and industrial machinery applications.

- Gray iron’s graphite microstructure provides high compressive strength, wear resistance, and thermal conductivity.

- Engine blocks and cylinder heads benefit greatly from gray iron due to its ability to handle heat and stress.

- Gray iron casting allows for durability, performance, and cost-efficiency in manufacturing engine components.

The Integral Role of Gray Iron in Machinery Manufacturing

Within the machinery manufacturing sector, gray iron castings play a critical role due to their inherent attributes that cater to heavy-duty applications. These attributes make gray iron a preferred material in various machinery and equipment production processes at KT-Foundry. Across numerous industries such as agriculture, automotive, construction, and transportation, gray iron castings contribute significantly to the durability and resilience of components and structures.

This high versatility, combined with cost-efficient production methods, make gray iron a go-to choice for items exposed to challenging service conditions. Some common gray iron casting applications include:

- Engine components

- Hydraulic components

- Pumps and valves

- Gearboxes

- Suspension systems

- Braking systems

As a result of these advantages, gray iron has established itself as an industrial grade material essential for manufacturing durable machinery components that withstand the rigorous demands of various sectors. In conclusion, the integral role of gray iron in machinery manufacturing cannot be overstated, as it continues to serve as the backbone of performance-driven and reliable industrial components in today’s world.

Unlocking the Attributes of Gray Iron Castings

What sets gray iron apart in the cast iron family is its unique graphite microstructure. This composition not only gives it its distinctive gray coloration upon fracture, but also provides an array of beneficial properties that make it ideal for several industrial applications. Let’s delve into the material composition and explore the strength and durability of gray iron castings.

The Composition and Appearance of Gray Iron

At the heart of gray iron’s properties are the graphite flakes dispersed within its matrix. These flakes account for the self-lubricating characteristic that enhances the machinability of gray iron, allowing us at KT-Foundry to create components with intricate designs and precise tolerances. The graphite microstructure also lends itself to the gray color observed when the material fractures, hence the name “gray iron.”

Strength and Durability: The Workhorse of Industrial Components

Gray iron stands out due to its impressive strength and wear resistance, enabling it to be a stalwart material in the production of durable industrial parts. The hardness of gray iron is primarily attributed to its material composition, which is bolstered by the graphite flakes present in the microstructure. These factors, combined with gray iron’s cost-effectiveness, position it as the workhorse material that reliably supports a range of industrial applications.

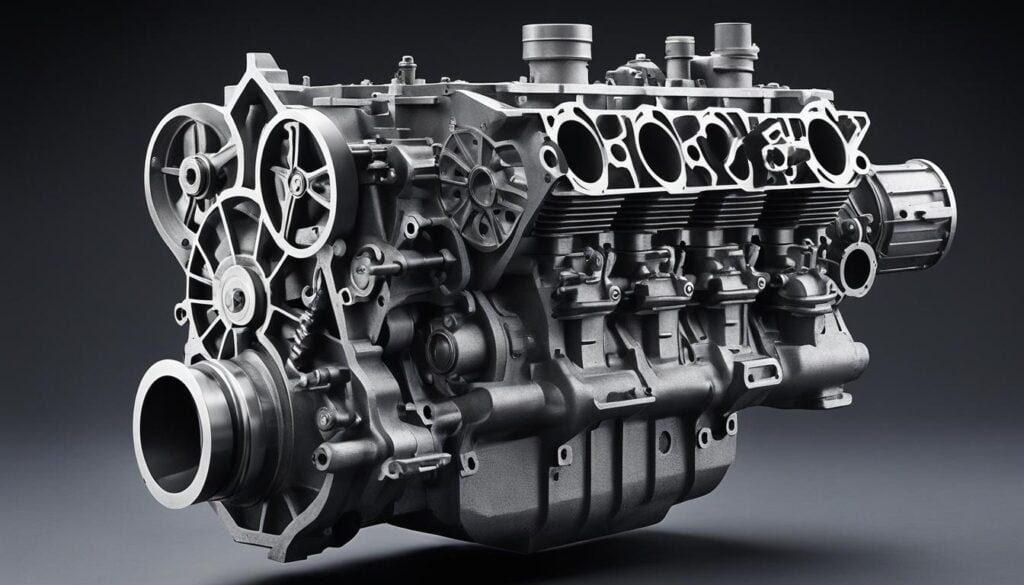

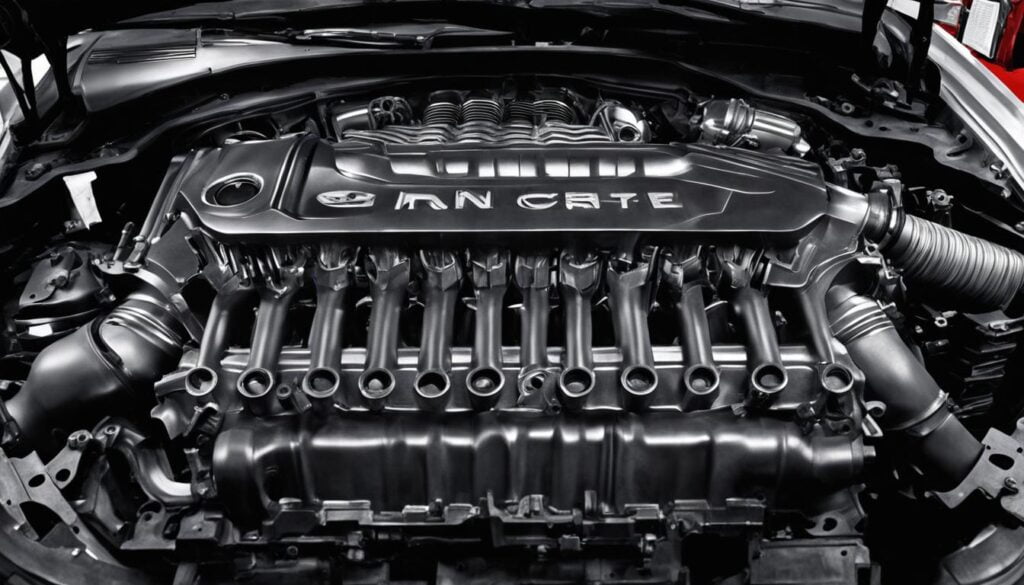

Exploring the Applications of Gray Iron Castings in Engine Components

Gray iron’s remarkable properties, such as thermal conductivity and resistance to deformation under stress, make it the ideal choice for manufacturing crucial engine components. They perform exceptionally well despite the extreme temperatures and pressures faced by an operating engine. In this section, we will delve into the applications of gray iron castings in cylinder blocks and heads and gear systems.

Cylinder Blocks and Heads: Withstanding Heat and Stress

Engine block castings made of gray iron provide outstanding thermal conductivity that aids in maintaining the optimal temperature for peak engine performance. At KT-Foundry, we leverage gray iron’s impressive properties to create durable and efficient cylinder blocks and heads, capable of withstanding the rigors of continuous engine operation. In addition to handling high heat and stress, these gray iron components ensure a longer service life for engines across various industries.

Gray Iron in Gear and Power Transfer Systems

Gear systems play a crucial role in transmitting power and torque to various parts of an engine. Gray iron’s wear resistance and load-bearing capacity make it an exceptional choice for the production of gears and gearboxes. These components benefit greatly from gray iron’s capabilities, ensuring efficient power transmission and minimal wear through countless operational cycles. The following table illustrates some of the essential gray iron properties that make it ideal for such applications:

| Property | Description | Benefit |

|---|---|---|

| Wear Resistance | Resistance to wear caused by friction or contact | Increased component lifespan; lower maintenance requirements |

| Load-bearing Capacity | Ability to handle high loads and forces | Reduced likelihood of component failure; allows for efficient power transfer |

| Thermal Conductivity | Efficient transfer of heat away from a component | Improved performance under high temperatures; reduced risk of overheating |

In conclusion, gray iron castings exhibit outstanding properties that make them indispensable in various essential engine components. At KT-Foundry, we remain committed to harnessing the advantages of this versatile material to deliver reliable, efficient, and high-performance automotive components to our clients.

Cost-Efficiency and Machinability: Advantages of Gray Iron Casting

At KT-Foundry, we recognize the substantial industrial cost savings accomplished through cost-effective castings using gray iron. These savings can be attributed to the material’s ease of machining gray iron and low production costs.

These advantages, however, extend beyond initial savings. Our gray iron components offer high production efficiency and long-term value due to their capacity for intricate detailing and consistent performance. By specializing in a material that is as economic as it is reliable, we deliver components that help optimize both the manufacturing process and the end-product functionality for our clients.

| Benefits | Examples |

|---|---|

| Cost-effective | Low melting temperatures, economical production processes |

| Ease of Machining | Graphite flakes provide self-lubrication, simplifying machining processes |

| Industrial Cost Savings | Reduced operational costs, increased efficiency in manufacturing |

| Long-term Value | Durable components, consistent performance over time |

In conclusion, our commitment to utilizing gray iron as a resource-efficient material ensures that we are offering our clients not just cost-effective castings but also reliable, high-performing components that have a long-term positive impact on their operations.

Sustainability and Recyclability of Gray Iron Casting

At KT-Foundry, our commitment to sustainability and eco-friendliness extends to every aspect of our gray iron casting processes. We emphasize energy-efficient casting methods, use of recyclable materials, and responsible waste management practices for the production of our high-performance engine components.

Eco-friendly Manufacturing Processes

As part of our drive towards sustainable gray iron production, we prioritize the use of recycled scrap iron, which significantly reduces the environmental footprint of our manufacturing activities. By employing energy-efficient casting processes that result from the lower melting point of gray iron, we minimize the consumption of energy resources and emissions released into the environment.

The Lifecycle of Gray Iron: From Scrap to Component

Our dedication to sustainability is reflected throughout the entire lifecycle of our gray iron castings. From raw material sourcing to finished industrial components, we consistently strive for eco-friendly practices that contribute to the responsible use of resources. This commitment includes recycling scrap iron to maximize material value and minimize wastage, ensuring that our products not only meet the high-performance demands of our clients but also promote a sustainable future for the industry.

FAQ

What are some advantages of gray iron castings in engine components?

Gray iron castings provide several advantages for engine components, including high compressive strength, exceptional wear resistance, and thermal conductivity. These properties make gray iron ideal for components such as engine blocks and cylinder heads, which must withstand intense heat and stress.

In what industries are gray iron castings commonly used?

Gray iron castings are widely used in various industries, such as agriculture, automotive, construction, and transportation. The material’s versatility, durability, and cost-efficiency make it highly popular for heavy-duty applications and parts exposed to challenging service conditions.

What are the unique properties of gray iron that make it suitable for industrial applications?

Gray iron is characterized by its graphite microstructure, which imparts attributes like high strength, wear resistance, and self-lubricating properties. The graphite flakes in gray iron allow for intricate designs, precise tolerances, and impressive strength, making it a reliable choice for durable industrial parts.

How does gray iron contribute to the production of gears and gearboxes?

Gray iron’s wear resistance and load-bearing capacity make it an essential material for producing gears and gearboxes. Its ability to transmit power efficiently while minimizing wear across countless cycles of operation proves instrumental in the performance and durability of such components.

Why is gray iron casting considered a cost-effective manufacturing process?

Gray iron casting is cost-effective due to its ease of machinability and low production costs. The material’s inherent properties allow for intricate detailing and consistent performance, contributing to both manufacturing process optimization and end-product functionality.

How does KT-Foundry prioritize sustainability and recyclability in gray iron casting?

At KT-Foundry, sustainability is a core value that informs our gray iron casting processes. We use recycled scrap iron to reduce the environmental footprint of our manufacturing activities, while the gray iron casting process’s energy efficiency lowers energy consumption and emissions. The recycling aspect of gray iron contributes to the lifecycle of the material, demonstrating our commitment to eco-friendliness.