Ferrous and non-ferrous metals are both great for projects that require metal use. Both have their own advantages, but distinctions are critical for understanding their characteristics and applications. These metals were already used as the Iron Age and Copper Age started.

A Closer Look at Ferrous Metal

Their physical properties and excellent corrosion resistance make them a good use for different applications because of its iron ore content.

Ferrous materials are highly recyclable, which makes them a sustainable option for manufacturing. They can be recycled into new products with minimal loss of material or quality.

The hue of a ferrous metal is the most apparent method to identify it. However, most ferrous metals may be darker or lighter, like carbon steel.

Most Common Ferrous Metals

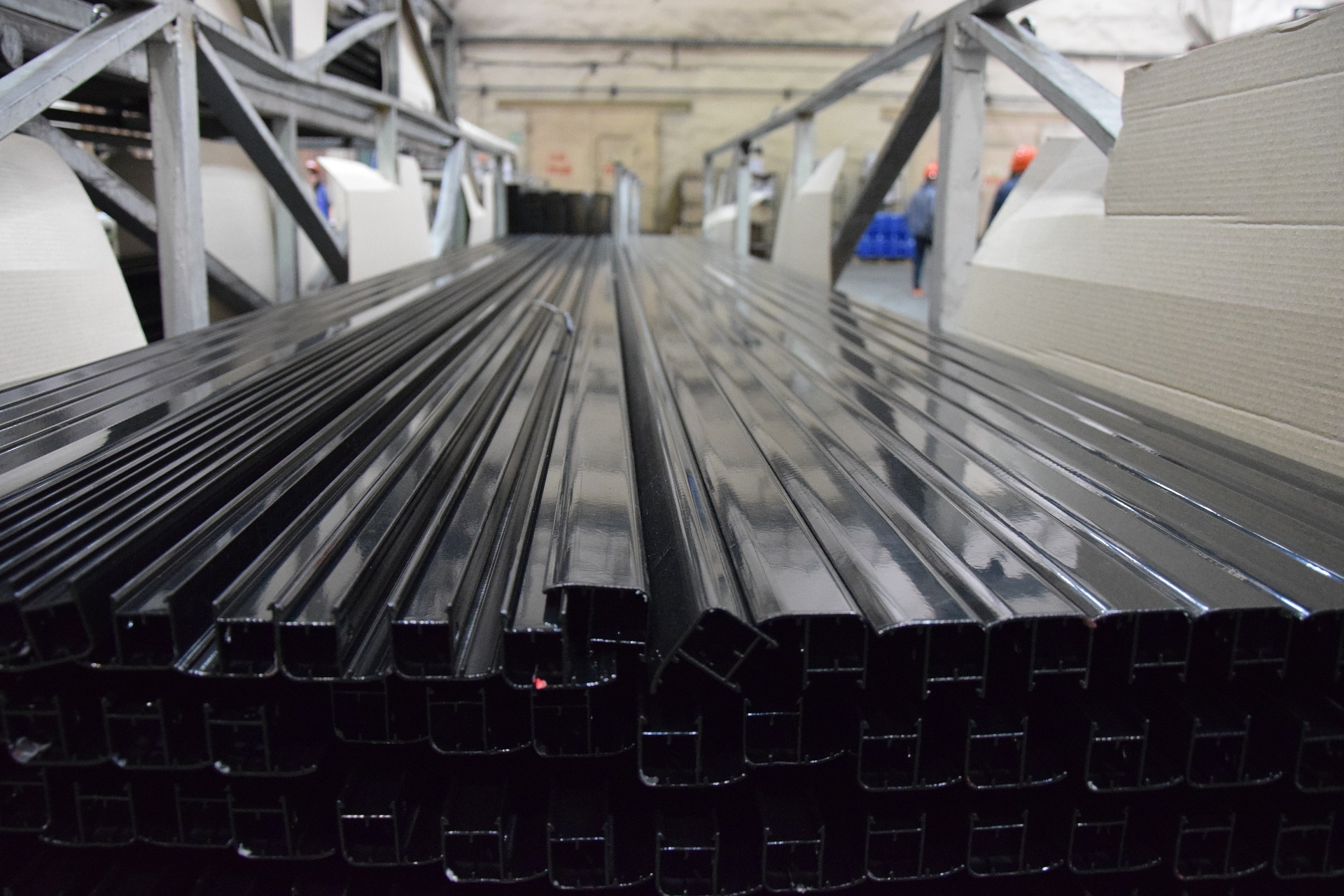

The most common ferrous metal examples include carbon steel, stainless steel, cast iron, wrought iron, and alloy steel, each with its unique properties and applications. Understanding the properties and uses of these ferrous metals can help industries make informed decisions when selecting materials for their projects.

Cast Iron

The construction industry is the major consumer of this ferrous metal. It is also used in cookware due to its ability to retain and distribute heat evenly.

It is often used instead of steel because it is cost-effective and has excellent tensile strength and durability.

Wrought Iron

It is extremely versatile and used in everything from bridges to decorative fences. It is known for its durability, strength, and aesthetic appeal.

Stainless Steel

Because of the versatility of its versatility, stainless steel is common in metal fabrication services, construction, and manufacturing industries.

Distinctive Properties of a Ferrous Metal

The reaction of the ferrous metal to magnets implies that if ferrous metals are put in a magnetic field, they will become magnetized and attract other ferrous metals.

What Projects Ferrous Metals are Good

Because of the properties mentioned, they are better for machine tools and electrical components. The construction industry uses them as reinforcing bars, industrial piping, structural steel frames, and beams.

How to Know If it is a Non-Ferrous Metal

Identifying a non-ferrous metal can be done in various ways, although one should always exercise caution. One of the most common methods of identification is to use a magnet.

It is also possible to determine a metal’s composition using a chemical test or spectrograph. Their physical properties can also identify these.

Most Common Non-Ferrous Metals

Aluminum

Aluminum is a lightweight, malleable metal often used in manufacturing aircraft parts, automotive parts, and other products due to its ability to resist corrosion and low density. It is also widely used in the production of food cans and foil. It is also used in electronics, as it is an excellent conductor of electricity.

Copper

Copper is one of the most common non-ferrous metals used in various industries and applications. It can be recycled repeatedly without losing quality, making it an ideal choice for long-term projects.

Tin

Tin is one of the most common non-ferrous metals found in nature, and it has a wide range of applications in industry. It is non-toxic and corrosion-resistant, making it a popular choice for many consumer products. It is a relatively soft metal with a silvery-white color and a low melting point.

Distinctive Properties Manufacturers and Consumers Like About Non-Ferrous Metal

They weigh ligher than ferrous metals, making them easier to work with. This is especially beneficial in applications that require the metal to be moved or carried.

Non-ferrous metals can be polished to a mirror-like finish, or they can be anodized to create beautiful colors. This makes them ideal for decorative applications, such as jewelry and artwork.

Bottomline for Ferrous and Non-ferrous Metals

Every project requires different characteristics. There are some that require metals that prevent rust, magnetic properties, and tensile strength that are not found in precious metals. Knowing the difference between ferrous metals and non-ferrous metals, especially its iron content will help you identify which is better for the properties that your project require.