Heat treatment can help change the quality of metal casting. It changes the physical and mechanical properties of the castings with the use of a furnace.

Heat treated metals possess improved mechanical properties by using a specific temperature during the cooling and heat treatment processes.

Heat Treatment Process: Why Should This Be Done

Heat treatment methods can be used to enhance the properties of metals and alloys, such as strength, ductility, toughness, wear resistance, and corrosion resistance.

The purpose of heat treatments is to improve the performance of a material while avoiding any detrimental effects. It involves extreme temperatures to change the internal structure.

What Does Heat Treatment Do to Mechanical Properties?

The metal castings undergo a controlled heating and cooling process. Furnaces that use direct heat can be used to harden a metal casting, while furnaces with indirect heat can be used to soften a metal casting. Through the application of heat, metal castings can be hardened, softened, or tempered.

Increasing the Tensile Strength by Heat Treating

To increase the tensile strength of a casting, metal heat treatment of the casting is required. This process involves heating the casting to a certain temperature and then cooling it down slowly in order and under a specific temperature.

A slow cooling rate allows the casting to retain the strength and hardness it has gained from the heat treatment. A rapid cooling method may cause the casting to become brittle and reduce the strength of the casting.

The temperature that must be reached is determined by the material that the casting is made of. For example, steel castings require a higher temperature than aluminum castings. Annealing is used to soften the casting, tempering is used to harden the casting, and normalizing is used to improve the uniformity of the microstructure of the casting.

Improving Machinability

Heat treatment is especially important for castings, which have a tendency to have low machinability due to the presence of porosity and other casting defects. Heat treatment can help reduce or eliminate these defects, resulting in improved homogeneous structure.

Heat treatment can improve the machinability of the casting by reducing or eliminating casting defects, such as porosity. This can result in an improved surface finish and reduced tool wear.

It is also used to improve the machinability of aluminum and other non-ferrous metals.

Heat treatment process is relatively easy to perform, and it can help to reduce production time and costs. Ultimately, it can be an effective way to improve the machinability of castings and reduce production costs.

Better Dimensional Accuracy

The heat treatment process helps to improve the dimensional accuracy of the castings, as it is less likely that the metal will deform or warp due to wear and tear.

Heat treating metal can be used to reduce the number of impurities present in the metal, which can improve the dimensional accuracy of the metal casting by making them less likely to contain defects.

By improving the grain structure, strengthening the metal, increasing its machinability, and reducing impurities, heat treatments can help to improve the dimensional accuracy of castings.

Quality for Long-Term Use

The resiliency of the metal casting increases as it undergoes heat treatment. For these materials, the process involves heating the material to between 950°C and 1200°C. The quenching process causes the molten metal to become harder and apply a durable wear layer. For non-steels, water quenching method is used.

Heat treatment is especially effective in increasing the wear resistance of ductile castings. For these castings, the process involves heat treating the material to between 800°C and 900°C and then rapidly cooling it for a solid solution.

By carefully controlling the temperature and cooling speed of the material, the microstructure of the material can be altered in order to create a more stable and wear-resistant material.

Types of Heat Treatment Processes

There are several different types of heat treating processes for castings. These include annealing, normalizing, case hardening, and tempering. Each of these processes has its own advantages and disadvantages, so the best one for your application depends on the specific requirements of the part.

Heat treating is used to reduce the risk of defects and improve the performance of the part.

Annealing

Annealing is usually used for hardened steel that is exposed to elevated temperatures and pressures. The process helps to reduce internal stress and strain in the casting, which in turn increases its fatigue resistance. It also helps to reduce internal porosity and improve the homogeneity of the material.

The annealing process involves heating the casting to a predetermined temperature in an atmosphere that is free of oxygen. The atmosphere is usually provided by either a furnace or an inert gas atmosphere.

The heat treated metal has its own annealing temperature. It can be determined by the use of thermal analysis or a mathematical model.

If the temperature or cooling rate is too high, the casting can become too brittle, prone to failure, and will not tolerate internal stresses. On the other hand, if the cooling rates has lower temperatures, the casting may not gain the desired mechanical properties.

Normalizing

This is generally used on castings that are made from low-carbon steel, iron-based alloys, or cast iron.

As the heat treated casting is cooled, it undergoes recrystallization, which helps to refine the grain structure and improve the mechanical properties and perfect casting of the material.

Normalizing is a relatively simple and inexpensive heat treatment process. It is typically performed on castings that require improved metal’s ductility or toughness. It is important to note that normalizing does not change the chemical composition of the material; only the grain structure is affected.

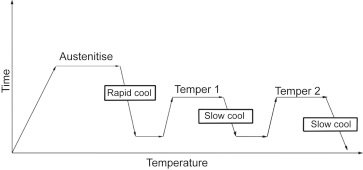

Tempering Process

Tempering is an important heat treatment process for castings, as it can improve the overall properties of the casting and help to ensure that the metal has different properties and incredibly versatile.

It is an important step in the production of most metals and should be carefully considered when deciding which heat treatment process to use. It also helps to reduce any stress and cracking that may have been caused during casting.

Heat Treated Metals

Metal components from automobiles, aircraft and other industrial applications undergo heat treatment. Heat treatment is used to improve the appearance of metals, such as by giving them a polished finish.

Not all metals need to undergo heat treatment. You should consider first which properties are needed for a specific application.

Steel

Steel is a popular choice for heat treatment because it can be hardened to a greater degree than other metals. Heat treatment can increase the strength and wear resistance of steel, making it an ideal choice for applications that require durability.

Aluminum

Aluminum is lightweight and malleable, making it a good choice for heat treatment. Heat treatment can be used to improve the strength and ductility of aluminum, making it suitable for applications that require weight savings and strength.

Aluminum is especially suited to heat treatment, as it is easy to work with and can tolerate higher temperatures than other metals. Heat treatment increases aluminum’s physical properties and resistance to oxidation, making it ideal for use in salty or acidic environments.

Titanium

Titanium is a strong and lightweight metal that can be heat-treated to improve its strength and wear resistance. Heat treatment can also be used to improve the corrosion resistance and weldability of titanium, making it an ideal choice for applications that require strength.

Like with other metals, the heat treatment makes titanium tough and durable. This is important for applications that will be subject to cyclic loadings, such as aerospace and medical components.

Copper

Copper and brass are malleable metals that can be heat treated to improve their strength and ductility. The heating process can also be used to improve the corrosion resistance of copper and brass, making them suitable for applications that require resistance to rust.

A primary benefit of treating copper is that it increases the strength and hardness of the metal. Copper is a soft metal, which makes it difficult to use in some applications.

It makes the metal more suitable for use in areas that require materials with a high strength-to-weight ratio, such as aircraft engines, power tools, and medical devices.