At KT-Foundry, we recognize the critical role gray iron castings play in the pump and valve components industry. These castings are integral to various industrial applications due to their excellent balance of strength and value. We deliver cast iron parts that include both the casing and internal parts, precisely machined to meet each unique application’s specifications. Serving markets in hydraulics, water, oil & gas, chemical, and food processing requires strict adherence to quality and performance, which we ensure through rigorous testing and measurement procedures.

Key Takeaways

- Gray iron castings are crucial in the pump and valve components industry for their strength and value.

- KT-Foundry iron castings are used in various industrial applications, including hydraulics, water, oil & gas, chemical, and food processing.

- Each cast iron part is precisely machined to meet the unique specifications of individual applications.

- Strict adherence to quality and performance is upheld through rigorous testing and measurement procedures.

- Gray iron castings offer numerous benefits that make them a preferred choice across multiple industries.

Understanding the Basics of Gray Iron Castings in Industry

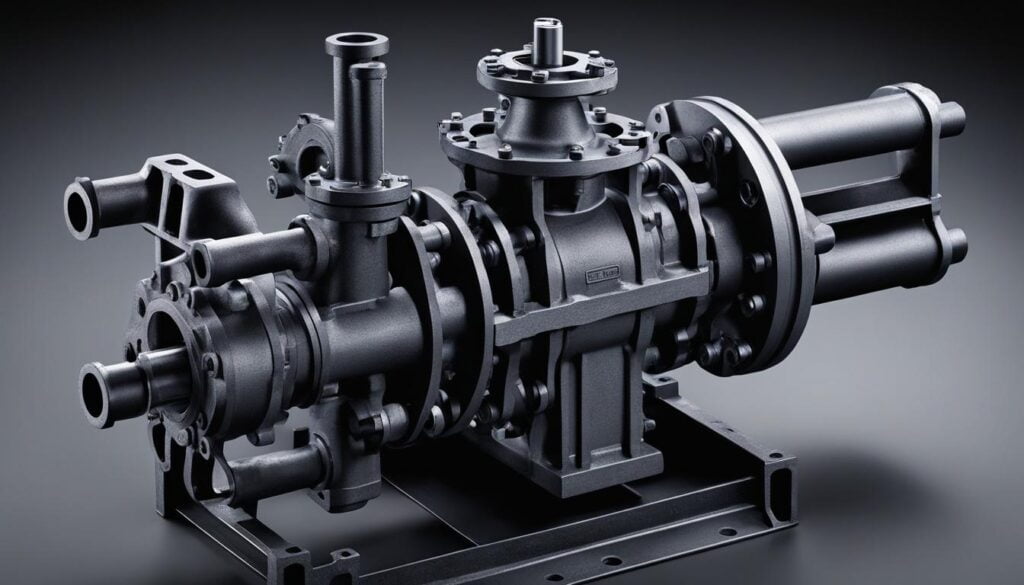

Gray iron castings from KT-Foundry are indispensable in the manufacturing of robust pumps and valves needed across various industries. With its distinctive characteristics, gray iron emerges as a cornerstone of pump and valve manufacturing, playing an essential role in producing engine components, hydraulic systems, gears, and gearboxes. In this section, we delve into the specifics of gray iron and how our expertise at KT-Foundry allows us to produce high-quality iron castings that cater to demanding industrial requirements.

The Role of Gray Iron in Pump and Valve Manufacturing

The unique gray hue of gray iron castings stems from the graphite microstructure present in its composition. This microstructure not only offers an aesthetic appeal but also provides crucial self-lubricating features that prove beneficial to pump and valve operations. In pump manufacturing and valve manufacturing applications, industrial gray iron castings are highly sought after for their ability to withstand intense heat, wear, and corrosive environments, while still guaranteeing the required strength and durability.

Key Properties of Gray Iron That Benefit Industrial Components

Various properties make gray iron one of the most highly-valued materials for producing industrial components. Among the most notable are its:

- High compressive strength: this allows components to withstand significant loads and stresses

- Excellent vibration dampening capabilities: this reduces operating noise and decreases wear and tear on machinery

- Good heat dissipation: this helps maintain structural stability and prevent premature thermal degradation

- Self-lubricating graphite flakes: these provide smooth operation and reduce the need for additional lubricants

These advantageous properties make gray iron incomparable in creating industrial components that optimize performance, durability, and cost-effectiveness.

KT-Foundry’s Expertise in Producing High-Quality Iron Castings

At KT-Foundry, our years of experience have enabled us to master the production of high-quality gray iron castings that adhere to the most stringent industry standards. Our commitment to excellence and continuous improvement ensures that each casting, be it for pump or valve manufacturing applications, meets the impressive balance of strength, precision, and value that has become synonymous with KT-Foundry.

Gray Iron Castings: Defining Pump and Valve Performance

Gray iron castings play a crucial role in determining the performance of pumps and valves within critical infrastructure. Their inherent properties such as high compressive strength, wear resistance, and excellent vibration dampening are vital for ensuring smooth and efficient operation of these components in today’s demanding industrial settings. These properties are indispensable in gray iron casting applications.

Gray iron castings contribute to optimal pump and valve performance by providing exceptional wear resistance, vibration dampening, and high compressive strength.

One crucial factor contributing to pump performance is the material choice for the pump casing and internal parts. Gray iron castings offer the necessary durability and corrosion resistance, enabling pumps to perform efficiently in extremely demanding environments. Similarly, gray iron casting applications play a crucial role in defining valve performance by offering the required strength and rigidity to withstand continuous operational stresses.

Given the importance of pump and valve performance in various industries, choosing gray iron castings for their components ensures reliable operation under tough conditions. Facilitating seamless industrial processes, gray iron castings are at the core of pumps and valves that drive productivity and profitability for businesses worldwide. As these applications continue to evolve, the utilization of gray iron castings remains beneficial, providing optimum performance where it matters most.

The Manufacturing Excellence of KT-Foundry’s Iron Castings

At KT-Foundry, we take pride in our manufacturing excellence, which is fortified by our ISO 9001 certification and firm commitment to high standards in the production of gray and ductile iron castings. Our unmatched iron castings are a testament to our state-of-the-art machining capabilities and meticulous quality testing protocols, ensuring that we meet and exceed the expectations of our Original Equipment Manufacturer (OEM) partners.

ISO 9001 Certified Processes at KT-Foundry

Our ISO 9001 certification heralds our dedication to upholding rigorous quality management systems throughout our production processes. We promote customer satisfaction by consistently delivering iron castings that demonstrate exceptional value and performance in their respective applications.

Quality is the cornerstone of our business; our proven track record in achieving ISO 9001 certification validates our commitment to meeting the strictest industry requirements.

State-of-the-Art Machining and Quality Testing Methods

Our advanced machining techniques and cutting-edge equipment empower us to produce iron castings with exacting precision and durability. We utilize the latest CNC technology to ensure the finest iron casting quality testing and post-production finishing processes.

With a focus on continuous improvement, we invest in research and development to explore more efficient and effective methods of machining and quality assurance. This adaptability and innovation have fortified our reputation for delivering unparalleled gray iron castings nationwide.

| Machining Capabilities | Quality Testing Methods |

|---|---|

| CNC Milling | X-ray Inspection |

| CNC Turning | Ultrasonic Testing |

| Grinding | Magnetic Particle Inspection (MPI) |

| Drilling | Liquid Penetrant Inspection |

| Deburring | Dimensional Testing |

In conclusion, KT-Foundry’s iron casting manufacturing excellence is exemplified by our ISO 9001 certification, advanced machining capabilities, and stringent quality testing methods. This unwavering dedication to quality control cements our reputation as a trusted provider of top-notch gray iron castings to our OEM partners spanning various industries nationwide.

Cast Iron Parts: Where Strength Meets Precision

Cast iron parts from KT-Foundry marry industrial strength with precise iron castings, offering OEMs a reliable solution for a wide range of fluid processing and hydraulic system applications. The marriage of strength and precision ensures that these components can endure the demanding nature of industrial environments while maintaining their exceptional performance standards.

Here are some notable examples of how cast iron parts provide the perfect combination of robustness and accuracy in crucial industrial components:

- Hydraulic pump casings that withstand high pressure and temperature fluctuations

- Valve bodies with exact internal contours to maintain tight tolerances

- Gearbox housings designed to dampen vibrations and limit wear

- Centrifugal impellers with intricate designs for optimized fluid flow

- Rotor hubs that ensure consistent power transfer in wind energy systems

At KT-Foundry, we have honed our expertise in producing cast iron parts that meet the stringent requirements of high-functioning fluid processing and hydraulic system components.

| Component | Material | Properties | Applications |

|---|---|---|---|

| Hydraulic Pump Casing | Gray Iron | High Durability, Temperature Resistance, Vibration Dampening | Fluid Processing, HVAC Systems |

| Valve Body | Gray Iron | Tight Tolerances, Corrosion Resistance, Structural Integrity | Oil & Gas, Chemical Processing, Water Treatment |

| Gearbox Housing | Gray Iron | Vibration Dampening, Wear Resistance, Stability | Automotive, Heavy Machinery, Renewable Energy |

| Centrifugal Impeller | Gray Iron | High Strength, Intricate Designs, Efficient Fluid Flow | Water Pumps, HVAC Systems, Marine Applications |

| Rotor Hub | Gray Iron | Rigidity, Durability, Consistent Power Transfer | Wind Energy Systems |

In conclusion, cast iron parts stand as a testimony to the perfect blend of strength and precision, ensuring that OEMs can rely on them to maintain the high performance and durability required across various industries.

Engineering the Core of Hydraulic Systems with Gray Iron

At KT-Foundry, we focus on creating core components for hydraulic systems using gray iron, an ideal material for the demanding environments these systems operate in. Our expertise in manufacturing hydraulic components such as gray iron pump housings and durable valve bodies ensure that all systems are designed for optimal performance and long-lasting durability.

Optimizing Hydraulic Pump Housings for Stressful Environments

Hydraulic systems are essential in various industries, and hence, their components must be designed to withstand the challenging conditions they are exposed to. Gray iron pump housings provide corrosion resistance and dimensional stability, which prolongs the life of the hydraulic system, ensuring equipment reliability and efficient functioning. This optimal performance is achieved due to gray iron’s superior mechanical properties, which allow it to resist wear and tear even under the most demanding conditions.

Valve Bodies and Their Reliance on Iron Cast Durability

Valve bodies are another vital component of hydraulic systems, with durability and strength being crucial aspects for their design. Gray iron proves to be the material of choice due to its high tensile strength, rigidity, and resistance to continuous operational stress. These qualities enable gray iron valve bodies to meet industry standards while providing the performance and longevity expected of top-quality hydraulic systems.

By employing gray iron in engineering the core components of hydraulic systems, we at KT-Foundry provide the foundation for reliable and efficient machinery, ensuring exceptional performance and endurance in even the most demanding industrial settings.

Gray Iron Castings: A Cost-Effective Material Choice

Gray iron castings offer a multitude of advantages that translate directly into cost savings and production efficiencies for our clients. Our clients appreciate gray iron for its cost-effectiveness, allowing the creation of complex parts without sacrificing quality or performance. In this section, we explore the various factors contributing to the cost-effective nature of gray iron castings, highlighting its value as the go-to material choice for industrial applications.

Using cost-effective gray iron for manufacturing pump and valve components allows businesses to enjoy significant savings while maintaining high-quality and performance standards. Materials matter as they play a vital role in determining the overall cost of production. Gray iron boasts multiple benefits that make it an ideal choice:

- Lower raw material costs

- Efficient and faster casting processes

- Ability to machine complex parts with precision

- Less need for expensive secondary operations

- Superior strength and durability

Industrial manufacturers should consider material choice carefully, as it can directly impact their bottom line. Gray iron is the preferred option for many industries, thanks to its cost-effectiveness in producing components with high-performance capabilities and long lifespans. Its exceptional mechanical properties, combined with more affordable production techniques, result in true iron casting value.

Here we present a summary of the key benefits an organization can gain while choosing gray iron castings for various applications:

| Benefits | Explanation |

|---|---|

| Lower Raw Material Costs | Gray iron is an abundant, readily available resource with lower costs compared to steel or other materials. |

| Faster Casting Processes | Gray iron is cast more quickly and efficiently, resulting in reduced lead times and overall production costs. |

| Precision Machining | Gray iron allows for precise machining and complex design capabilities without sacrificing product quality. |

| Reduced Secondary Operations | Components made of gray iron often require fewer secondary procedures, further reducing costs and production time. |

| Strength and Durability | Despite its cost-effectiveness, gray iron exhibits high tensile strength and superior wear resistance, increasing the lifespan of components. |

When looking to optimize production costs without compromising on quality or performance, gray iron is an excellent material choice, offering a winning combination of affordability, versatility, and durability. By utilizing cost-effective gray iron castings, organizations can enhance their productivity, increase their economic competitiveness, and ultimately deliver better products to their customers.

Sustaining Machinery with the Durability of Gray Iron Components

The sustainability of machinery is significantly enhanced by the durability of gray iron components. Gray iron, with its outstanding wear resistance and natural vibration dampening properties, proves to be a preferred choice across various industries. This essential material enables engine blocks and gear systems to achieve extended service lives, while also contributing to heavy machinery’s stability and longevity.

How Engine Blocks and Gear Systems Garner Longevity

For durable machinery components like engine blocks and gear systems, gray iron is indispensable due to its superior wear resistance and strength. Its self-lubricating graphite flakes offer a friction-reducing advantage, minimizing wear and tear and ensuring maximum service life. This capability makes gray iron an ideal material for high-stress applications, ensuring reliable performance even in the most demanding environments.

The Anti-Vibration Advantage in Heavy Machinery Applications

Heavy machinery often experiences significant amounts of vibration during operation, which can lead to premature wear, structural damage, and decreased efficiency. Gray iron’s inherent anti-vibration properties help attenuate these vibrations, providing a more stable working environment. The graphite flakes within gray iron create a damping effect that absorbs and disperses vibrations, significantly reducing the impact on the machinery components. This advantage ensures that heavy machinery operates more smoothly and experiences a longer operational life.

From Historical Origins to Modern Applications of Gray Iron

Gray iron has a storied history, with its origins in ancient China and subsequent development over centuries into a material cornerstone in machinery and equipment manufacturing. KT-Foundry leverages this rich heritage and modern technological advancements to continue delivering top-quality gray iron castings that meet the evolving needs of industry, embodying both tradition and innovation in our processes.

The Evolution of Gray Iron Use in Machinery Manufacturing

The use of gray iron dates back to the 4th century BC, when ancient Chinese civilizations began utilizing its advantageous properties in the manufacturing of various tools and equipment. Over time, gray iron became increasingly popular in the production of machinery components due to its impressive mechanical properties such as high compressive strength, excellent thermal conductivity, and remarkable wear resistance.

In the industrial revolution, gray iron played a vital role in the development of steam engines, railway systems, and agricultural machinery. Its ease of casting, machining, and affordability positioned it as a preferred material for manufacturing these essential components. Today, modern iron casting applications have expanded to include engines, gearboxes, pumps, valves, and countless other critical components across multiple industries.

How Technological Advancements Have Shaped Current Gray Iron Casting Processes

Technological advancements in casting techniques have significantly improved the quality and consistency of gray iron castings, enabling manufacturers to meet increasingly demanding specifications and tolerances. For instance, computer-aided design and manufacturing (CAD/CAM) technologies have revolutionized the process of creating complex molds and cores, ensuring greater accuracy and precision in the final product.

In addition, advanced casting simulation software helps engineers visualize the entire casting process, from mold filling to solidification, which helps in identifying and mitigating potential defects. The implementation of state-of-the-art quality control processes, such as 3D scanning and x-ray techniques, also contribute to refining the overall gray iron casting quality. These technological advancements have paved the way for modern gray iron casting applications that continue to push the boundaries of what was once thought possible.

In conclusion, the history of gray iron plays an integral role in the evolution of machinery and equipment manufacturing. At KT-Foundry, our commitment to harnessing the past and embracing modern technological advancements ensures that our gray iron castings continue to meet the demands of industries and equipment manufacturers around the world.

Conclusion

As a leading entity in the realm of gray iron castings, KT-Foundry has consistently delivered top-notch product solutions that drive the success of our clientele in pump and valve manufacturing industries. Our dedication to upholding the highest standards, impactful outcomes, and enduring excellence has cemented our reputation as a trusted partner within this domain.

Consolidating KT-Foundry’s Industry Leadership in Gray Iron Castings

We continuously strive to enhance our leadership in this sector through the application of advanced manufacturing methodologies, rigorous testing procedures, and steadfast adherence to quality benchmarks. Our iron castings showcase the perfect balance of industrial-grade resilience, precision, and sustainability, ensuring that each component we craft is an embodiment of lasting value.

Future Perspectives: The Continued Importance of Gray Iron in Pumps and Valves

Looking forward, we at KT-Foundry remain convinced of gray iron’s enduring relevance in the manufacturing sphere, particularly when it comes to pumps and valves. Rooted in the material’s multifaceted benefits, ranging from its distinctive mechanical properties and cost-effectiveness to its inherently eco-friendly nature, gray iron’s presence in machinery production will only continue to gain prominence as industries evolve. This unwavering reliance on gray iron will further fortify our commitment to upholding its excellence through our pioneering solutions and services as a true industry leader.

FAQ

What are the main applications of gray iron castings in the pump and valve components industry?

Gray iron castings are used in various industrial applications due to their excellent balance of strength and value. The castings are integral to pump and valve components, including the casing and internal parts, precisely machined to meet each application’s specifications. KT-Foundry serves markets in hydraulics, water, oil & gas, chemical, and food processing.

What are some key properties of gray iron that benefit industrial components?

Gray iron’s distinctive graphite microstructure provides essential self-lubricating features beneficial to pump and valve operations. This microstructure makes gray iron a cornerstone for producing engine components, hydraulic systems, gears, and gearboxes. It offers high compressive strength, wear resistance, and excellent vibration dampening necessary for smooth and efficient operation in industrial settings.

How does KT-Foundry ensure the production of high-quality iron castings?

KT-Foundry is recognized for its manufacturing excellence, underscored by its ISO 9001 certification and commitment to high standards in the production of gray and ductile iron castings. They employ state-of-the-art machining capabilities and quality testing regimes to guarantee every iron casting meets precise specifications and durability needs of OEM partners.

How do gray iron castings affect pump and valve performance?

Gray iron castings are pivotal in defining the performance of pumps and valves within critical infrastructure. They provide high compressive strength, wear resistance, and excellent vibration dampening necessary for the smooth and efficient operation of these components in demanding industrial settings.

What are the advantages of using gray iron in hydraulic systems?

Hydraulic pump housings benefit from gray iron’s corrosion resistance and dimensional stability, while valve bodies rely on the material’s tensile strength and rigidity to withstand continuous operational stresses. Gray iron also offers natural vibration dampening properties, which contribute to the stability and longevity of heavy machinery.

Why is gray iron considered a cost-effective material choice?

Gray iron offers a multitude of advantages that translate directly into cost savings and production efficiencies for clients. Its cost-effectiveness allows for the creation of complex parts without sacrificing quality or performance, making it a preferred choice across various industries.