At KT-Foundry, we acknowledge the integral role of ductile iron castings in various industries, admired for their remarkable strength, durability, and adaptability. Ductile iron is recognized for its tensile strength and ductility due to the presence of graphite in nodular form, availing superior toughness and flexibility when compared to traditional gray cast iron.

Industries appreciate the durability of ductile iron castings in applications where demanding specifications and operational scenarios are common. In this comprehensive guide, we delve into the world of ductile iron, exploring its unique composition, manufacturing process, and the numerous advantages it brings to engineering applications, showcasing the versatility of ductile iron castings across various sectors.

Key Takeaways

- Ductile iron boasts superior tensile strength and ductility compared to traditional gray cast iron.

- Graphite nodules in ductile iron’s composition contribute to its exceptional strength and flexibility.

- Ductile iron castings find extensive use in industries like automotive, construction, and agriculture, demonstrating their versatility for various applications.

- Manufacturing ductile iron castings involves melting, molding, and post-casting treatments for enhanced performance and durability.

- Cost-effectiveness, corrosion resistance, and machinability are among the numerous advantages offered by ductile iron castings.

An Introduction to Ductile Iron Castings and Their Place in Industry

Ductile iron castings are a vital cornerstone in contemporary engineering, finding their way into numerous industrial applications thanks to their exceptional tensile strength and endurance. Castings made of this highly-specialized iron fare exceedingly well in heavy-duty tasks, making them an indispensable component in sectors such as automotive, construction, and agriculture. This widespread adoption of the material is primarily attributed to the presence of graphite in spheroidal form within the castings, granting them unique mechanical properties that rival those of traditional gray cast iron counterparts.

The presence of graphite in a spherical shape within the castings extends crucial benefits, providing versatility that serves various sectors like automotive, construction, and agriculture.

Among the most notable industrial applications of ductile iron castings are automotive components, water system fittings, agricultural machinery, and heavy construction equipment. These sectors demand materials capable of withstanding the weight, vibration, and harsh environmental conditions inherent to their application. Owing to its nodular cast iron use and functionality, ductile iron castings rise to the challenge, providing the durability and flexibility required for long-term operation and performance.

To further appreciate the contribution of ductile iron castings to modern-day engineering, let us delve into the sectors where they play a pivotal role:

- Automotive Industry: Employed in the production of chassis, suspension systems, engine blocks, and brake components, ductile iron castings ensure enhanced performance and safety in vehicles.

- Construction Industry: Utilized in structural support systems, heavy equipment, and machinery, ductile iron castings are integral to the erection and completion of large-scale projects like bridges, tunnels, and roads.

- Agriculture Industry: Harnessed in the manufacturing of plows, tractors, harvesters, and irrigation systems, ductile iron castings facilitate the sturdy and reliable operation of essential agricultural equipment.

In conclusion, the utilization of spheroidal graphite iron in ductile iron castings opens up a world of possibilities for engineering applications in various domains. As the demand for stronger, more resilient materials continues to grow, it is clear that ductile iron castings will remain a pivotal player in meeting the ever-evolving requirements of these industries.

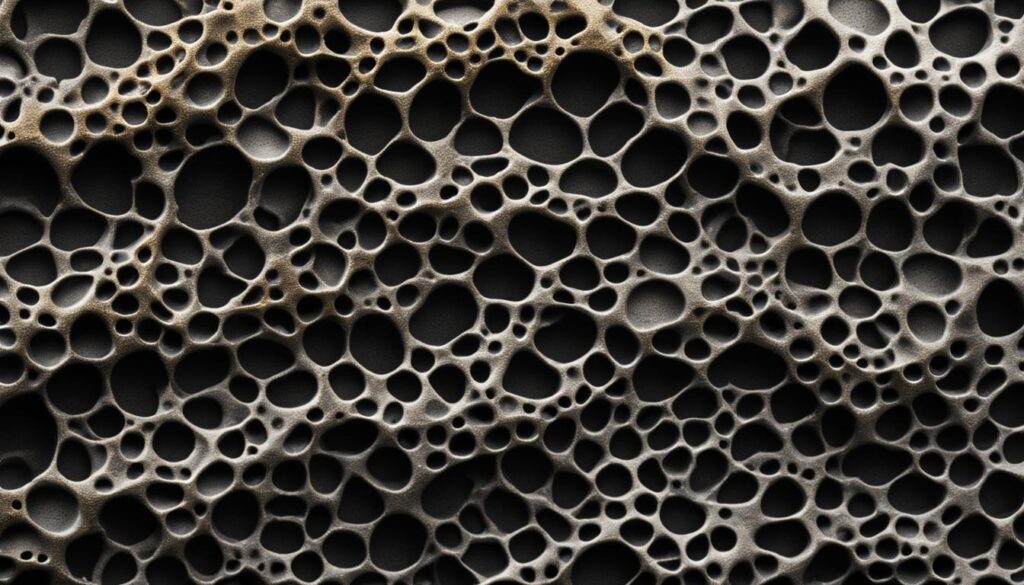

Unveiling Ductile Iron: Understanding Its Unique Composition

At the heart of ductile iron alloy lies its distinct composition that sets it apart from traditional gray cast iron. One of the primary factors contributing to the superior mechanical properties of ductile iron is the presence of graphite nodules. These graphite nodules in ductile iron are instrumental in providing the material with unparalleled pliability and resilience, making it a preferred choice for demanding engineering tasks. Let’s delve deeper into the cast iron microstructure and discover the role of these nodules in achieving such remarkable properties.

Ductile iron is known for its impressive tensile strength, ductility, toughness, and adaptability, owed to the nodular form of graphite within its composition.

Here, we present a table comparing the microstructures of ductile iron and traditional gray cast iron, underscoring the distinguishing features of both materials.

| Type of Iron | Microstructure | Graphite Type | Properties |

|---|---|---|---|

| Ductile Iron | Nodular | Spheroidal | High tensile strength, Ductility, Toughness, Resistance to fatigue |

| Gray Cast Iron | Flaky | Lamellar | Brittle, Excellent wear resistance, Ideal for vibration damping |

As seen in the table, the spherical or nodular graphite structure in ductile iron results in greater tensile strength, ductility, and toughness. On the other hand, traditional gray cast iron, which contains flaky lamellar graphite, primarily offers excellent wear resistance and vibration damping properties but is comparatively more brittle.

In summary, the unique composition of ductile iron, characterized by the presence of graphite nodules within its microstructure, grants the material an exceptional blend of strength, ductility, and resistance to fatigue, making it the go-to choice for a wide range of engineering applications.

The Ductile Iron Casting Process: From Melting to Final Product

At KT-Foundry, the production journey of ductile iron castings encompasses a series of crucial steps, ensuring the highest quality final product. Through a blend of melting and molding, post-casting treatments, and a rigorous quality assurance protocol, we’re dedicated to delivering top-grade ductile iron components to serve manifold sectors.

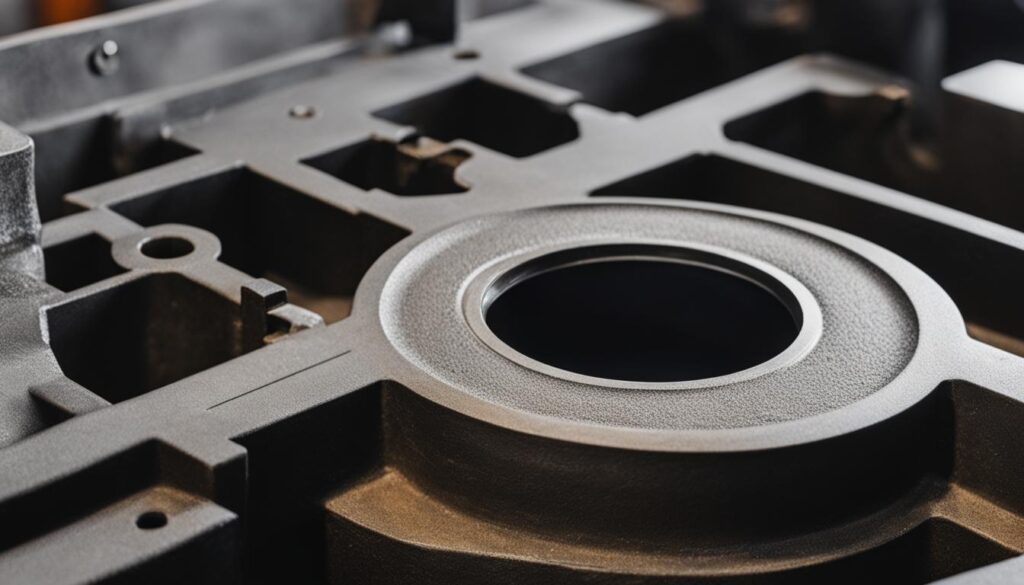

Melting and Molding: The Alloy Takes Shape

Creating ductile iron castings begins with the ductile iron melting process, where iron is carefully blended with alloying elements. Once achieved, the molten alloy is poured into predetermined cast iron mold designs, shaping the final product. The mold’s design is integral in achieving desired geometries, catering to an array of engineering solutions.

Post-Casting Treatments: Heat Treatment and Surface Finishing

Certain ductile iron castings necessitate heat treatment of ductile iron to enhance their mechanical properties, allowing them to meet the demands of specific applications. Furthermore, ductile iron surface finishing treatments contribute to increased durability and performance, ensuring the cast iron products thrive in challenging environments.

Quality Assurance: Ensuring Top-Grade Ductile Iron Castings

To uphold our commitment to excellence, KT-Foundry implements a meticulous quality assurance procedure. Each casting undergoes a thorough ductile iron casting inspection for surface and structural defects, ensuring defect detection in castings. Our quality control procedures verify that only superior ductile iron products are produced, fortifying a sense of trust and reliability in the industries we serve.

| Process Stage | Description |

|---|---|

| Melting and Molding | Iron and alloying elements are melted and subsequently poured into cast iron mold designs to form the final product. |

| Post-Casting Treatments | Heat treatment and surface finishing enhance the mechanical properties and durability of ductile iron products. |

| Quality Assurance | Each casting is meticulously inspected for defects, ensuring adherence to our stringent quality control procedures. |

Exploring the Multifaceted Advantages of Ductile Iron Castings

Ductile iron castings stand out as a premier engineering material, boasting a wealth of advantages that cater to the needs of various industries. Among these remarkable attributes are their impressive tensile strength, inherent corrosion resistance, and exceptional machinability. These qualities promote intricate designs while ensuring cost-effective manufacturing processes.

Let’s delve further into the primary benefits of employing ductile iron castings:

- Tensile strength: The tensile strength of ductile iron arises from its unique microstructure, characterized by graphite nodules that allow for the iron to withstand significant loads without succumbing to fractures. This quality makes ductile iron an invaluable resource in designing components for heavy-duty infrastructure and industrial applications.

- Corrosion resistance: Another significant advantage of ductile iron castings lies in their natural resistance to corrosive elements. This ensures that the material can endure long-term exposure to harsh environments and maintain its structural integrity, translating to extended service life and fewer maintenance requirements.

- Machinability: Ductile iron’s excellent machining capabilities enable manufacturers to create detailed, complex designs with precision and ease. This allows for the production of tailor-made components catering to specific industrial requirements.

| Advantages | Explanation | Industry Applications |

|---|---|---|

| Tensile strength | High load-bearing capacity without fractures | Automotive, construction, heavy machinery |

| Corrosion resistance | Can endure long-term exposure to harsh environments | Pipes, valves, water and sewage infrastructure, maritime equipment |

| Machinability | Creation of intricate designs with ease and precision | Aerospace, automotive, consumer products |

In summary, ductile iron castings offer a multitude of advantages that make them the material of choice for a range of industrial applications. By leveraging their unique strengths, manufacturers can develop engineering solutions tailored to the specific needs of their target sectors, delivering high-quality products that consistently meet or exceed performance expectations.

Ductile Iron Castings’ Pivotal Role in Mainstream Manufacturing

In today’s rapidly evolving manufacturing landscape, ductile iron castings have emerged as a fundamental ingredient in crafting innovative solutions. With their unparalleled combination of cost-effective iron castings, heavy-duty cast iron properties, and versatility, ductile iron’s contribution to modern manufacturing processes cannot be overstated.

Endowed with exceptional tensile strength and wear resistance, ductile iron castings find their application in reinforcing heavy equipment and infrastructure, ensuring optimal performance and longevity. This remarkable material’s adaptability enables the fabrication of intricate parts, pushing the boundaries of traditional engineering to create more efficient, resilient, and durable solutions.

Moreover, the economic benefits derived from ductile iron in manufacturing manifest as:

- Lower production and material costs owed to its efficient casting process

- Lessened need for additional reinforcements due to its high strength-to-weight ratio

- Reduced maintenance and replacement expenses on account of its long service life

From augmenting heavy equipment to enabling the production of intricate parts, ductile iron castings provide a dependable foundation in modern manufacturing processes.

In conclusion, the burgeoning presence of ductile iron castings within current manufacturing practices underscores their immense value and potential impact in contemporary engineering. As the industry continues to evolve and innovate, ductile iron castings serve to bolster the drive for novel, robust, and cost-effective solutions, cementing their primacy in mainstream manufacturing.

Real-World Applications of Ductile Iron Castings Across Industries

Ductile iron castings play a significant role in multiple industries, offering unparalleled strength, longevity, and versatility in various applications. From the automotive sector to water and civil infrastructure, and the agricultural sphere, these castings have proven to be a reliable and efficient choice for manufacturers and engineers alike.

The Backbone of the Automotive Industry

In the automotive industry, where performance and safety are critical factors, ductile iron castings serve as the backbone of various components. Engine blocks, automotive suspension parts, and brake components casting rely on this versatile material to ensure robustness and longevity under the dynamic and intense pressures encountered on the road.

Foundation of Water and Civil Infrastructure

With its prolonged service life and resistance to environmental stressors, ductile iron is a predominant choice for water and civil infrastructures. Ductile iron pipes, water system fittings, and sewage system castings are essential components for reliable water and wastewater systems worldwide. Its durability and cost efficiency make it an ideal choice for engineers and municipalities when building long-lasting, sustainable infrastructure.

Essential Material for Agricultural Machinery

The agricultural realm greatly benefits from the application of ductile iron castings for crafting durable machinery parts. Components such as plowshares, tractor part castings, and irrigation system components require resilience to withstand the repetitive and rugged use encountered in varying environmental conditions. By utilizing ductile iron in pivotal agricultural tools and equipment, farmers and engineers can rely on a material that offers both durability and affordability in their daily operations.

Cost-Effectiveness: Analyzing the Economic Impact of Ductile Iron Castings

Ductile iron castings demonstrate immense cost-effectiveness by addressing key concerns within various industries. Their long service life results in decreased replacement frequency, ensuring durability and longevity for demanding applications. Moreover, the reduced machining costs and an excellent strength-to-weight ratio contribute to overall economic efficiency, making ductile iron castings a wise choice for businesses to harness their full potential.

Below, we offer a comparative analysis of the cost-effectiveness factors of ductile iron castings in relation to other materials:

| Material | Long Service Life | Reduced Machining Costs | Strength-to-Weight Ratio |

|---|---|---|---|

| Ductile Iron Castings | High | High | High |

| Gray Iron Castings | Medium | Medium | Low |

| Steel Castings | High | Low | Medium |

| Aluminum Castings | Low | Medium | High |

As shown in the table, ductile iron castings have the upper hand in delivering benefits that can lead to substantial economic savings. The comparison highlights the value of investing in this versatile material, streamlining operations to remain competitive and cost-effective.

Ductile Iron Castings and the Environment: A Study of Sustainability

As a responsible engineering material, ductile iron castings not only offer a multitude of advantages in terms of strength and adaptability but also align with sustainable manufacturing practices. By promoting recyclability, reducing carbon footprints, and optimizing energy efficiency, ductile iron manifests as an eco-friendly alternative in the vast expanse of engineering disciplines.

Recycling and Reusability: Ductile Iron’s Eco-Friendly Edge

Ductile iron plays a crucial role in sustainable cast iron production due to its highly recyclable nature, enhancing the material’s environmental-friendliness. Recyclability of ductile iron enables repurposing and reusability, which subsequently leads to a reduction in raw material sourcing and diminishes the carbon footprint of our operations. By embracing the green philosophy, we at KT-Foundry, strive to make ductile iron an environmentally responsible choice in the engineering sphere.

Lower Energy Use in Production: An Eco-Conscious Choice

Our commitment to sustainability goes beyond the mere recycling of materials; we also champion an energy-efficient casting process for the production of ductile iron castings. This streamlined process requires significantly less energy compared to the manufacturing of competing materials, translating to substantial reduced emissions and underlining our alignment with eco-friendly ideologies.

As an illustration of our energy-conscious endeavors, the following table presents a comparative analysis of the energy consumption in the production of ductile iron compared to its counterparts:

| Material | Energy Consumption (MJ/kg) |

|---|---|

| Ductile Iron | 20.1 |

| Gray Cast Iron | 22.5 |

| Aluminum Alloys | 58.0 |

| Steel | 32.0 |

Our dedication to sustainable manufacturing practices, highlighted through the recyclability of ductile iron and the optimization of energy usage in production, places eco-conscious material sourcing as an utmost priority. These environmentally responsible choices not only elevate the reputation of ductile iron castings as a versatile and durable engineering material but contribute to a cleaner and greener future for all.

Enhanced Material Properties of Ductile Iron Castings

As a versatile and resilient choice among engineering materials, ductile iron castings offer an ideal balance of strength and flexibility, along with impressive longevity in harsh environments. With superior ductility and corrosion resistance, these cast iron products are uniquely positioned to withstand the rigorous demands of various applications.

Combining Strength with Flexibility: The Best of Both Worlds

Ductile iron castings boast a high ductility, enabling components to endure bending and dynamic stresses without failure. This flexibility under load is critical for engineering materials where deformation is a common occurrence. The presence of nodular graphite within the cast iron contributes to these mechanical properties, allowing for increased toughness and resilience compared to traditional gray cast iron.

Weathering the Elements: Corrosion Resistance in Ductile Iron

One of the many advantageous properties of ductile iron castings is their inherent corrosion resistance, which allows for prolonged service life and longevity in harsh environments. This durability ensures consistent performance across a wide range of applications, particularly those exposed to aggressive elements. As a result, ductile iron castings offer a dependable and durable cast iron solution for the many industries they serve.

Ductile Iron Castings: A Unique Engineering Material

As an unrivaled engineering material, ductile iron castings have proven paramount in various industries, attributing to their unique combination of high tensile strength, resistance against fatigue, and superior impact absorption. This comprehensive spectrum of properties has enabled innovative material applications, paving the way for continuous progress across the multiple dimensions of modern engineering disciplines.

Ductile iron’s versatility renders it an ideal material for complex structures and heavy-duty tasks where the amalgamation of strength and flexibility is imperative. This has resulted in the development of a wide range of engineering solutions, from automotive components, heavy machinery, water distribution systems, to civil infrastructure.

By putting ductile iron at the forefront of engineering innovation, we witness a dramatic upsurge in material efficiency and performance, resulting in unprecedented advancements in the manufacturing sector.

Some notable applications of ductile iron castings in contemporary engineering include:

- Automotive and aerospace industry: Engine blocks, suspension systems, and brake components.

- Construction and infrastructure sectors: Ductile iron pipes, fittings, manhole covers, and other civil engineering solutions.

- Agriculture and heavy machinery: Plowshares, tractor components, irrigation systems, and gears.

Ultimately, ductile iron castings have earned their reputation as a distinctive material that caters to the ever-evolving demands of modern engineering. By harnessing the full spectrum of benefits attributed to ductile iron, we can continue to propel technological advancements and create efficient solutions for a plethora of industries.

Conclusion

In the realm of modern-day engineering, the numerous benefits of ductile iron castings, such as their adaptability in design, sustainable manufacturing process, and performance-capacity in challenging scenarios, underline their importance. Our commitment at KT-Foundry is to capitalize on these advantages, ensuring that our clients are able to access the material’s full spectrum of utility.

Ductile iron castings have become a cornerstone in industry solutions, offering versatile engineering possibilities, owing to their high tensile strength, endurance, and novel properties perfected within our casting process. As the demand for innovative applications and continuous progress within various engineering fields increases, ductile iron castings will remain a crucial element in pushing the boundaries of manufacturing and construction.

At KT-Foundry, we take pride in offering top-quality ductile iron castings that cater to the diverse requirements of our esteemed clients. Our unwavering dedication is to provide the utmost in engineering solutions, establishing ductile iron castings as the preferred material for heavy-duty tasks, and fortifying their position as an indispensable asset in the engineering panorama.

FAQ

What are the main advantages of ductile iron castings?

Ductile iron castings offer a range of advantages, including impressive tensile strength, corrosion resistance, machinability, cost-effectiveness, and environmental sustainability. These benefits make them a popular choice for various industries.

What industries commonly use ductile iron castings?

Ductile iron castings are widely used in automotive, construction, agriculture, water and wastewater systems, and heavy machinery industries. These industries rely on the unique properties of ductile iron to manufacture robust and durable components.

How does the composition of ductile iron contribute to its unique properties?

Ductile iron owes its unique properties to the presence of graphite nodules in its microstructure. These nodules provide flexibility and toughness, resulting in superior tensile strength and ductility compared to traditional gray cast iron.

What is the ductile iron casting process at KT-Foundry?

The ductile iron casting process at KT-Foundry involves melting iron and alloying elements, pouring the molten material into molds, and undergoing post-casting processes such as heat treatment and surface finishing. Quality assurance and inspection also play a crucial role in ensuring top-grade ductile iron castings.

How do ductile iron castings contribute to cost-effective manufacturing?

Ductile iron castings offer cost savings through reduced machining time, longer service life, and a favorable strength-to-weight ratio. These factors reduce material costs, associated transportation expenses, and replacement frequency, making them an economically friendly choice for businesses.

Are ductile iron castings environmentally sustainable?

Yes, ductile iron castings are environmentally sustainable due to their recyclability and reusability, lower energy use in production, and reduced carbon footprint. All these factors contribute to a more sustainable manufacturing process while supporting eco-friendly manufacturing ideologies.

How does ductile iron withstand harsh environmental conditions?

Ductile iron castings demonstrate impressive corrosion resistance and durability in harsh environments due to their unique combination of high tensile strength, resistance against fatigue, and superior impact absorption. These properties make ductile iron an ideal choice for engineering components exposed to harsh conditions.