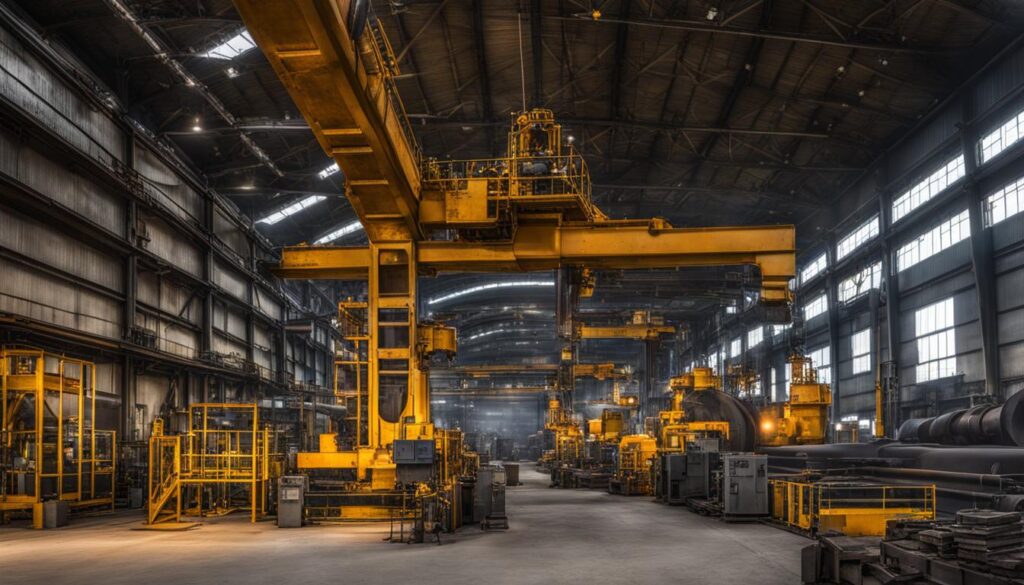

At KT-Foundry, we’re at the forefront of harnessing the exceptional properties brought forth by Alloy Steel Casting. Our dedication to innovation in metallurgy is evidenced by our use of sophisticated CNC Machining processes that maximize the corrosion resistance, hardenability, and the integration of alloying elements to guarantee enhanced performance. We take pride in providing our clients with superior alloy steel that stands up to the rigorous demands of a variety of industries.

The unique attributes of alloy steels, combined with our expert crafting, result in a material that is not just robust and durable but also exceptional in its ability to be shaped into precise components. Our commitment to quality and performance ensures that our customers receive only the best alloy steel castings, tailored to their specific functional requirements.

Key Takeaways

- Superiority of Alloy Steel Casting with tailored machinability.

- State-of-the-art CNC Machining enhances precision and efficiency.

- Exceptional corrosion resistance for longevity in harsh environments.

- Customizable hardenability to meet specific application needs.

- Integration of alloying elements provides versatile material properties.

- Enhanced performance underlines the superiority of alloy steel for industrial use.

Exploring the Benefits of Alloy Steel Castings

At KT-Foundry, our commitment to advancing industrial solutions is evident in the superior quality of our high strength alloys and industrial castings. The advantageous properties of alloy steel castings, particularly their high corrosion resistance and tailored material properties, position them as a material of choice in a range of demanding sectors. Before we dive into the specifics of how these castings enhance industrial applications, let’s understand their inherent characteristics.

Versatility Across Industrial Applications

Our industrial castings are celebrated for their adaptability, being employed in a multitude of environments that demand resilience and longevity. This versatility is rooted in a customizable makeup, which allows these alloys to perform exceptionally under varied conditions – whether it is in the depths of the ocean for maritime equipment or in the high-temperature environments of aerospace engineering.

Inherent Strength and Durability Enhancements

The presence of Chromium, Molybdenum, and other alloying elements in our castings amplifies their high strength and durability, key characteristics essential for long-lasting and reliable performance in demanding settings. From architectural structures to automotive components, these properties ensure a lifespan that withstands the test of time and use.

Customizing Heat Treatment for Optimal Performance

Through precision heat treating alloy steel, we fine-tune the properties according to the specific application needs of our clients. This customization aspect facilitates the achievement of target hardness, strength, ductility, and resistance levels, yielding a product that not only meets but exceeds the performance requirements of the industry.

| Alloy Element | Contribution to Strength | Contribution to Corrosion Resistance | Heat Treatment Impact |

|---|---|---|---|

| Chromium | Enhances tensile strength | Forms a protective oxide layer | Improves hardenability |

| Nickel | Increases toughness | Resists extreme temperatures and oxidizing conditions | Refines grain structure |

| Molybdenum | Boosts high-temperature strength | Prevents pitting in stainless steel | Enhances tempering response |

Deciphering the Alloy Steel Composition

At KT-Foundry, we are committed to not just producing alloy steel, but also to a deep understanding of its intricate makeup. This commitment enables us to generate materials that stand up to rigorous industrial applications with aplomb. The alloy composition of steel we develop is uniquely constructed, blending carbon and other alloying elements to create properties tailored for specific challenges faced by our clients. It’s this precise combination that crucially influences the alloy’s machinability, hardenability, and overall performance.

Crucial Role of Carbon and Alloying Elements

The carbon content in alloy steel is a pivotal factor, acting as a key determinant of its ductility and strength. However, that’s just the tip of the iceberg. Elements such as Manganese contribute to the creation of Manganese sulfides, which act as an internal lubricant during the machining process. This significantly enhances the steel’s machinability. At the same time, Silicon boosts the alloy’s strength and hardenability, ensuring that our steel can withstand the toughest of conditions without faltering.

Understanding the AISI/SAE Steel Designation System

Navigating through the complexities of various steel grades is made feasible thanks to the AISI/SAE steel designation system. This standardized nomenclature gives us a consistent framework to reference the specific attributes of different alloy steels. When we select materials for a particular application, understanding the AISI/SAE designation is critical. It is a language that speaks specifically to the chemical makeup of the steel – a language we at KT-Foundry are fluent in.

Common Alloying Elements and Their Impact

Each element we introduce to our alloy steel at KT-Foundry serves a strategic purpose. Beyond Manganese and Silicon, elements like Chromium and Nickel are selected to bolster corrosion resistance, allowing our products to exhibit resilience in the face of corrosive environments. This meticulous selection and blending process crafts an alloy composition that does not just meet, but exceeds the requirements of our diverse clientele by providing robust and reliable performance across a broad range of applications.

FAQ

What makes alloy steel casting advantageous for CNC machining?

Alloy steel casting is advantageous for CNC machining because of its excellent machinability. The presence of alloying elements like Chromium and Manganese improves the machinability of the steel, allowing for efficient and precise shaping to meet required specifications. This results in enhanced performance and a superior finish in the final product.

How does corrosion resistance benefit alloy steel castings in industrial applications?

Corrosion resistance is a key benefit of alloy steel castings, which is imparted by elements like Chromium and Nickel. This characteristic is especially critical in harsh environments where exposure to corrosive substances is common. With high corrosion resistance, alloy steel castings are more durable and maintain their integrity over time, making them ideal for use in aerospace, automotive, and construction industries.

What role does hardenability play in the quality of alloy steel castings?

Hardenability determines how well a steel can be hardened through heat treatment. Manganese and Silicon are alloying elements that enhance the hardenability of alloy steel. This is critical for achieving the desired strength and wear resistance in the casting, allowing it to perform effectively in demanding applications that require high strength alloys.

Can the properties of alloy steel castings be customized for different industrial applications?

Yes, the properties of alloy steel castings can be customized through the adjustment of carbon content and the selection of specific alloying elements. Heat treating alloy steel is another method used to tailor the material properties to meet the performance requirements of a range of industrial applications. These customized properties allow manufacturers to create specialized industrial castings that are optimized for their intended use.

What is the significance of the AISI/SAE steel designation system?

The AISI/SAE steel designation system is significant because it provides a standardized methodology for identifying and classifying alloy steels. It aids industry professionals in selecting the precise composition of alloy steel for their specific application, ensuring that they have the appropriate carbon content and combination of alloying elements to meet their project’s requirements.

How do common alloying elements like Manganese impact the properties of alloy steel?

Common alloying elements such as Manganese have a significant impact on the properties of alloy steel. Manganese, for instance, improves hardenability and tensile strength while acting as an internal lubricant during the machining process. It also helps in the formation of Manganese sulfides, which can enhance machining by reducing friction and tool wear. Each alloying element contributes to the overall composition and performance of the alloy steel, offering specific benefits in various applications.