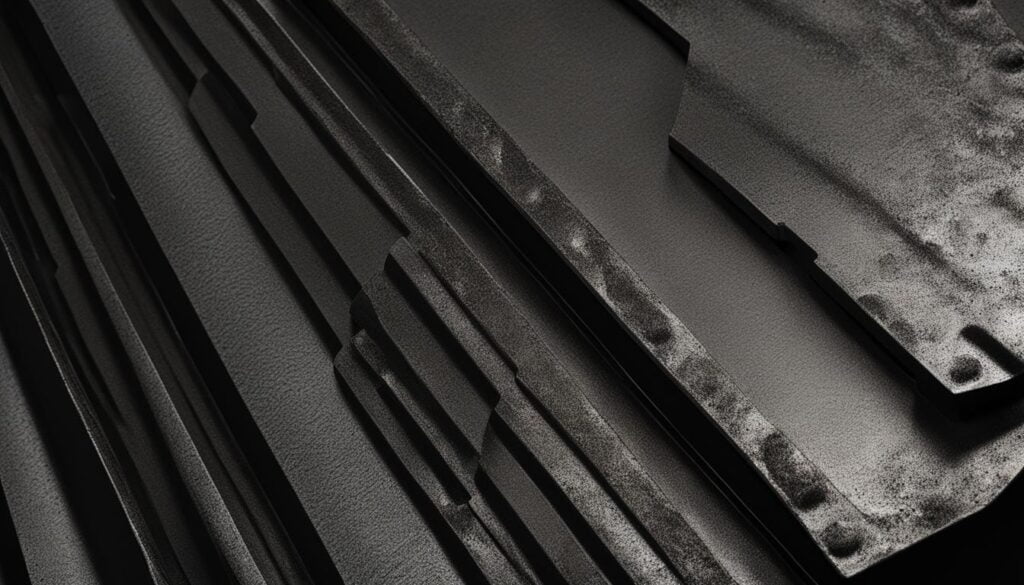

Manganese steel, commonly known as Hadfield steel or Mangalloy, is an alloy containing 12-14% manganese that is renowned for its exceptional impact strength and resistance to abrasion once in its work-hardened state. This ultimate work hardening steel boasts extensive use in various industrial applications ranging from mining and rail sectors to impenetrable safes and anti-drill plates. Manganese steel alloy not only elevates corrosion resistance, especially in moist atmospheres, through the adsorption of manganese ions, but also has a non-magnetic nature, making it uniquely suited for electronic transformer assemblies and industrial lifting magnets. Providers like KT-Foundry are focused on the manufacture and supply of manganese steel plates, capitalizing on this alloy’s wear resistance and durability in harsh working environments.

Key Takeaways

- Manganese steel, also known as Hadfield steel or Mangalloy, is an alloy made up of 12-14% manganese, contributing to its wear resistance and high impact strength.

- Self-hardening properties of manganese steel allow it to be used in several industrial applications such as mining, rail, and security.

- Non-magnetic nature of manganese steel makes it suitable for electronic transformer assemblies and industrial lifting magnets.

- Manganese steel demonstrates exceptional corrosion resistance, particularly in moist atmospheres, due to the adsorption of manganese ions.

- KT-Foundry is a provider of manganese steel plates, ensuring the production and supply of this durable, wear-resistant alloy for various industries.

Understanding Manganese Steel and Its Unique Properties

Manganese steel’s unique characteristics are primarily attributed to its high manganese content, typically in the range of 12-14%. This specific composition forms a robust alloy capable of withstanding high-impact forces. As-cast manganese steel exhibits a level of softness, scoring 187 BHN, or 10 Rc, but its strength and hardness remarkably increase upon exposure to impact due to the inherent work-hardening capacity.

The Composition of Manganese Steel

Notably, the yield strength of this alloy stands around 66,000 PSI, with an ultimate tensile strength of approximately 107,000 PSI. Additionally, it has a ductile core with an elongation of 35% over two inches. Manganese steel, or mangalloy, owes its impressive durability and impact strength to this specific chemical makeup, assisting in the alloy’s toughness even under harsh conditions.

Work Hardening: The Secret Behind the Strength

Mangalloy is unparalleled in its work-hardening ability. Upon repeated impact, the surface of manganese steel castings reaches a hardness level up to 550 BHN (55 Rc), although typically worn casting surfaces see a hardness range of 400–450 BHN. The capability to absorb vast amounts of energy via strain-hardening mechanisms underpins this notable feature.

Despite common misconceptions, manganese steel displays adequate abrasion resistance even before being work-hardened. However, its true resilience shines in applications designed for gouging and high-stress abrasion, where the potential for rapid work-hardening is substantial.

Understanding the manganese steel properties enables industries to harness these benefits and optimize their wear resistance in high-impact, heavy-duty applications. To make an informed decision about suitable alloys for specific operational environments, it is essential to consider manganese steel’s unique work-hardening potential and material characteristics.

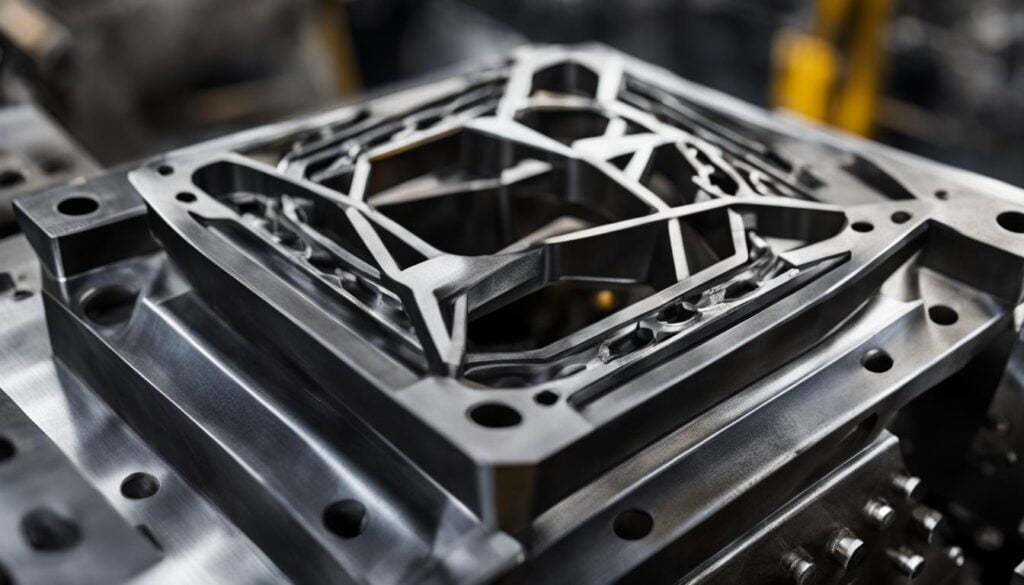

Manganese Steel in High-Impact Environments

Manganese steel fittings, due to their impressive work-hardening properties, are principally utilized in heavy-duty environments subject to high impact and wear. Industries rely on manganese steel for its ability to withstand repeated and powerfully impacting forces, making this alloy the go-to choice for high-impact applications. Some of the common uses of manganese steel in high-impact environments include:

- Mining machinery and equipment

- Rock crushing and aggregate production

- Railroad components

- Industrial crushers

| Industry | Application | Role of Manganese Steel |

|---|---|---|

| Mining | Crusher wear parts and liners | Provides increased wear resistance and durability in crushing equipment. |

| Rock Crushing | Impact hammers | Endures up to 10 times longer than mild steel under heavy-duty, high-impact conditions. |

| Railroad | Track components and coupling devices | Offers prolonged service life and reduced maintenance costs in high-impact environments. |

As evidenced by the table above, manganese steel can outperform other alternatives in high-impact applications that require robust wear resistance. Crushing equipment, in particular, benefits significantly from the inherent properties of manganese steel due to the demanding nature of its operational environment.

Manganese steel fittings are the preferred choice for industries with heavy-duty applications, offering unparalleled wear resistance and durability under high-impact conditions.

In summary, manganese steel’s excellent wear resistance and work-hardening properties are integral to its success in high-impact environments and heavy-duty applications. From mining machinery to railroad components, this alloy has proven to be an effective solution for industries requiring increased durability and toughness in their materials.

A Closer Look at Manganese Steel’s Abrasion Resistance

By examining manganese steel’s performance under various wear conditions, we can better understand its remarkable abrasion resistance. In particular, different prehardening techniques have been shown to influence the alloy’s dimensional stability and hardness.

Prehardening Techniques and Wear Performance

Interestingly, manganese steel castings that are prehardened using explosive techniques to offset the low initial yield strength display negligible plastic flow or dimensional changes, indicating a unique work-hardening mechanism. Although abrasive wear situations can wear into the castings, forming grooves across the surfaces, for applications where severe impacts are prevalent, manganese steel excels in wear resistance.

Prehardening methods such as mechanical or explosive techniques are adopted in railway track work, not to enhance wear resistance but to mitigate high maintenance costs by artificially increasing yield strength ahead of service. These practices allow manganese steel to maintain its durability while reducing overall expenses for industries that rely on the alloy’s wear-resistant properties.

“Prehardening manganese steel castings using explosive techniques offsets the low initial yield strength, leading to minimal plastic flow and dimensional changes.”

| Prehardening Techniques | Benefits |

|---|---|

| Explosive | Minimal plastic flow and dimensional changes due to unique work-hardening mechanism |

| Mechanical | Increased yield strength, reducing maintenance costs for industries |

In summary, manganese steel’s extraordinary abrasion resistance is a result of its unique work-hardening mechanisms and the strategic implementation of prehardening techniques. As industries continue to recognize the advantages of this alloy in high-impact environments, ongoing research and developments will likely lead to further improvements in manganese steel performance and wear resistance.

The Challenge of Machining Manganese Steel

Machining manganese steel presents significant challenges due to its hardened state and “zero machinability,” as cutting and grinding tools rapidly wear down. Special tooling, such as diamond or carbide, is necessary for drilling into this alloy. While oxy-acetylene torch cutting is possible, methods such as plasma or laser cutting are preferred.

In terms of welding, managing heat is crucial to prevent cracking, with an interpass temperature recommended to be below 500°F. Despite these challenges, manganese steel plate can be effectively joined, provided safety measures are taken due to the toxic nature of the weld fumes.

Effective Methods for Cutting and Welding

The metalworking challenges posed by machining manganese steel can be addressed by employing appropriate cutting and welding techniques. Some of the most effective methods include:

- Plasma cutting: This process utilizes a high-velocity jet of ionized gas to melt and remove the material, offering faster cut speeds and cleaner edges.

- Laser cutting: A focused laser beam is used to melt the material and expel it, providing high-speed cutting and greater accuracy compared to other techniques.

- Carbide and diamond tooling: Drilling into manganese steel alloy requires carbide or diamond tooling, which are less susceptible to wear and possess enhanced hardness and heat resistance.

In addition to cutting techniques, it is essential to adopt proper welding procedures when joining manganese steel plates. Some welding techniques include:

- Austenitic manganese steel welding: This method employs electrodes with suitable alloys, maintaining low interpass temperatures, and allowing adequate time for cooling before welding the next pass.

- Submerged arc welding (SAW): SAW provides a high-quality, metal-layered weld bead and is suitable for joining manganese steel plates, provided the right filler material is used.

- Gas metal arc welding (GMAW): Also known as MIG welding, GMAW is a versatile method capable of producing a high-quality weld by using a suitable filler material and adhering to proper heat management procedures.

By implementing these cutting and welding techniques, industries can overcome the challenges associated with machining manganese steel and take full advantage of its exceptional wear resistance and impact strength properties.

Enhancing Wear Resistance Through Alloy Modification

Manganese steel’s inherent properties can be further modified and enhanced through the introduction of other elements such as chromium, nickel, and vanadium. These alloy modifications lead to the creation of various grades with unique metallurgical characteristics tailored to specific service conditions. By adjusting the manganese steel composition through such modifications, steel foundries like KT-Foundry can optimize the material for its intended industrial application, thereby improving wear resistance and material longevity.

How Different Alloys Influence Manganese Steel’s Properties

Incorporating additional elements into manganese steel’s composition not only enhances its overall performance but also allows engineers to target specific characteristics relevant to different applications. Here is a brief look at some common alloy additions and their impact on manganese steel:

- Chromium: Enhances corrosion resistance, increases hardness, and improves wear resistance under low to moderate impact conditions.

- Nickel: Increases tensile strength, toughness, and impact resistance while providing austenitic stability under heat treatment.

- Vanadium: Stabilizes grain structure, resulting in increased strength, controlling grain growth, and promoting secondary hardening during hardening processes.

| Alloying Element | Effect on Manganese Steel |

|---|---|

| Chromium | Increased wear and corrosion resistance, increased hardness |

| Nickel | Increased tensile strength, toughness, and impact resistance |

| Vanadium | Increased strength, stabilized grain structure |

As seen from the table above, each alloying element adds specific benefits to manganese steel’s performance. Integrating these elements allows manufacturers to develop toughened alloys that cater to a wide range of industrial applications.

In conclusion, alloy modification plays an essential role in enhancing wear resistance and other desired properties in manganese steel. By selecting the appropriate alloy modifications, KT-Foundry can create manganese steel products that demonstrate outstanding performance in various industrial applications, showcasing the material’s versatility and adaptability to various service conditions.

The Non-Magnetic Nature of Manganese Steel in Industrial Applications

The non-magnetic nature of manganese steel is a vital characteristic that makes it suitable for many industrial applications. The particular attribute contributes to the reliable performance of components like electrical transformer assemblies and lifting magnets, as it avoids interference with magnetic fields. Although initially non-magnetic, over time and with consistent impact wear, affected areas can develop a slight magnetic property. This occurrence is unique to this type of metal, while non-impacted areas remain non-magnetic.

One of the primary reasons for the extensive use of non-magnetic manganese steel in industrial applications is its remarkable impact wear resistance. This property, coupled with its non-magnetic nature, makes it a preferred material in sectors where extreme wear and exposure to magnetic fields are common.

Key Industrial Applications of Non-Magnetic Manganese Steel

- Transformer assemblies

- Electric motor components

- Heavy-duty lifting magnets

- Protective housings for sensitive electrical equipment

“The non-magnetic characteristics of manganese steel, combined with its exceptional impact wear resistance, make it an attractive choice for industries where reliability and durability are paramount.”

In conclusion, non-magnetic manganese steel serves as an ideal material for various industrial applications due to its unique combination of high impact wear resistance and non-magnetic properties. The use of this alloy in sectors such as electrical transformer assemblies and lifting magnets ensures equipment safety and longevity.

Comparative Analysis of Manganese Steel and Other Wear-Resistant Alloys

While manganese steel is the material of choice for high toughness applications, its effectiveness under abrasion without impact is not superior to that of high carbon steel or even cast iron, both of which are heat-treated for hardness. For example, when dealing with non-impact abrasion, such as fine sand, the wear resistance of manganese steel does not surpass that of other steels. Therefore, selecting the appropriate wear-resistant alloy, like manganese steel, depends largely on the specific operational demands and nature of the materials being processed.

In this comparative analysis, we will examine the wear-resistant alloys available on the market and provide guidelines on when to choose manganese steel over its alternatives.

When to Choose Manganese Steel Over Alternatives

To facilitate the alloy selection process, it is essential to assess the toughness and wear resistance requirements of a given application. The following table illustrates the wear-resistant alloys commonly used in industries and their significant properties, enabling you to make a well-informed decision.

| Alloy | Wear Resistance | Toughness | Best Used For |

|---|---|---|---|

| Manganese Steel (Mangalloy) | High | Very High | High-impact applications, abrasive materials with impact, mining, and crushing equipment |

| High Carbon Steel | Medium | High | Non-impact abrasive wear, cutting tools, industrial knives |

| Cast Iron | Low to Medium | Low | Low-impact abrasive wear, wear-resistant coatings, pump components |

| Chromium Carbide | Very High | Low | Heavy abrasion without impact, wear plates, hardfacing applications |

In conclusion, manganese steel is the optimal choice for applications where high toughness and resistance to abrasion with impact are required. Situations involving non-impact abrasion or a need for a balance between toughness and wear resistance may call for alternatives such as high carbon steel or cast iron. By understanding the specific requirements of your application and the properties of various wear-resistant alloys, you can make an educated decision on the most suitable material for your needs.

Conclusion

In conclusion, manganese steel alloy is distinguished by its unparalleled impact strength and the ability for work-hardening, leading to exceptional wear resistance under appropriate circumstances. The unique properties of manganese steel make it the go-to material for high-impact, heavy-duty applications. However, its efficacy in low-impact abrasion scenarios is surpassed by other alloys. By introducing alloy modifications, manganese steel can be adapted to a wider range of requirements, further enhancing its applicability.

KT-Foundry leverages the impressive capabilities of manganese steel alloy, offering alloy steel castings that provide unparalleled durability in the most demanding environments. Understanding the distinctive properties of manganese steel, along with guidance from specialized providers like KT-Foundry, enables industries to unlock the full potential of manganese steel and other wear-resistant alloys.

In summary, manganese steel presents excellent wear solutions for various industrial applications, particularly in high-impact environments. Making calculated comparisons among wear-resistant alloys helps industry professionals to identify optimal wear solutions tailored to specific operational demands. By collaborating with experts like KT-Foundry, businesses can achieve an edge in longevity and performance across wear-prone industrial environments.

FAQ

What is manganese steel alloy and its primary uses?

Manganese steel, also known as Hadfield steel or mangalloy, is an alloy with 12-14% manganese content. It is renowned for its exceptional impact strength and resistance to abrasion when in its hardened state, making it the ultimate work hardening steel. Its uses range from mining and railroad components to impregnable safes and anti-drill plates due to its self-hardening properties and non-magnetic nature.

How does manganese steel achieve its unique work-hardening capacity?

Manganese steel’s work-hardening ability is due to its capability to absorb vast amounts of energy through strain-hardening mechanisms upon exposure to impact. This results in a noticeable increase in strength and hardness, with worn casting surfaces reaching a hardness range of 400-450 BHN.

In which industries is manganese steel mainly utilized?

Manganese steel fittings are mainly used in heavy-duty environments subject to high impact and wear, such as mining, rock crushing, railroad components, and metal aggregates. These industries rely on manganese steel for its ability to withstand repeated and powerfully impacting forces.

Can manganese steel be machined, and if so, how?

Machining manganese steel is challenging due to its hardened state and “zero machinability.” Special tools like diamond or carbide are needed for drilling, while plasma or laser cutting is preferred over oxy-acetylene torch cutting. Welding manganese steel can be done but requires careful management of heat to prevent cracking and knowledge of appropriate safety measures due to the toxic nature of the weld fumes.

How can alloy modifications enhance the wear resistance of manganese steel?

Manganese steel’s properties can be further enhanced by introducing other elements, such as chromium, nickel, and vanadium. This results in various grades with unique metallurgical characteristics tailored to specific service conditions. By adjusting the manganese steel composition, steel foundries like KT-Foundry can optimize the material for its intended industrial application, improving wear resistance and material longevity.

When should manganese steel be chosen over other wear-resistant alloys?

Manganese steel is the material of choice for high toughness applications but may not be the best option for non-impact abrasion situations. In such cases, high carbon steel or cast iron, both heat-treated for hardness, may be more effective. Selecting the appropriate wear-resistant alloy depends on the specific operational demands and nature of the materials being processed.