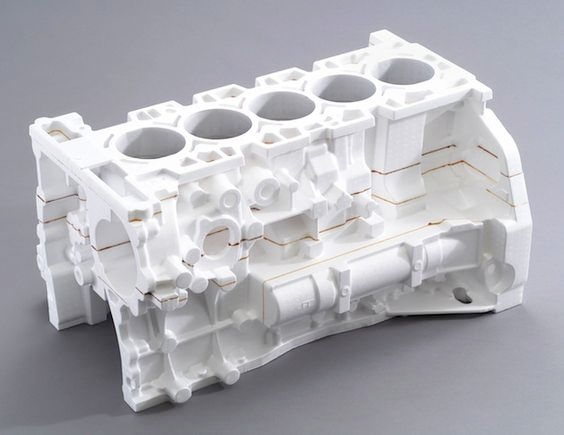

Lost foam casting process entails making a foam design out of refractory material to create the mold. Because of its numerous advantages, lost foam casting is a cutting-edge technology that is causing a stir in the manufacturing industry at the present time.

The foam design evaporates because of the heat of the molten metal. It fills the void and results in a high-precision and high-quality metal casting.

This article will explore the lost foam casting process in detail and discuss its numerous advantages, including design flexibility, cost-effectiveness, and reduced environmental impact.

The Lost Foam Casting Process

The manufacturing industry has seen significant advancements in recent years, with new techniques and technologies emerging to improve efficiency and reduce waste. It is also more cost-effective than other casting methods. It does not require expensive tooling or machining processes, unlike sand casting and investment casting.

Lost Foam Pattern Creation and Assembly

A computer-aided design (CAD) model is used to create the lost foam model. This model is then used to generate polystyrene foam patterns using various tools, including CNC machines, hot wire cutters, and 3D printers.

The foam pattern must be created to the exact specifications of the CAD model, as any deviations can result in defects in the lost foam castings.

Once the foam pattern is created, it is coated with a refractory material that will withstand the high temperatures of the liquid metal. This coating is typically a mixture of sand and binder applied to the foam pattern using a spray gun. The coating is allowed to dry, and additional layers may be added to achieve the desired thickness before coming to the production line.

This assembly process may involve gluing the designs together or using pins or other mechanical fasteners to hold the practices in place. Care must be taken to ensure the foam patterns are correctly aligned, as any misalignment can result in defects in the final casting.

Casting Process

The casting process requires careful process control, as any mistakes can result in defects in the final product.

One of the most critical aspects of pouring metal in lost foam casting is ensuring that the metal flows uniformly throughout the mold. This is because any inconsistency in the molten metal could result in defects in the final product.

The pouring metal process in lost foam casting also requires proper venting. This is necessary to prevent air pockets from forming in the mold, which can result in defects in the final product.

What Makes Lost Foam Casting Method Different from Other Casting Processes

Lost Foam casting is a unique and innovative method of casting that differs significantly from traditional casting processes. The use of foam pattern eliminates the need for expensive tooling and time-consuming mold-making, making the process faster and more cost-effective.

Another factor that contributes to the precision of lost foam casting is the ability to produce near-net-shape parts.

However, it also requires a high level of skill and expertise to produce high-quality parts, and can be time-consuming and difficult to control.

Advantages of The Lost Foam Casting Process

Dimensionally Accurate Castings

A refractory coating is applied to the foam design to create a hard shell that will protect the pattern and keep its dimensions consistent while it is cast. This is because lost foam casting eliminates the need for traditional mold-making processes, which can introduce errors and inconsistencies in the final product.

Consistent Surface Finish

Because the pattern is made in whole, it does not present any parting lines compared to other processes. The foam pattern used in the lost foam casting process has a uniform and smooth surface finish, which is transferred to the final product.

This eliminates the need for additional post-casting finishing operations, such as grinding, sanding, or polishing.

Reduced Environmental Impact

Fewer emissions are produced because less energy is used and less material is wasted than in conventional casting.

Lost foam casting eliminates the need for a traditional mold-making process, which can result in significant material waste. The foam pattern for this process is made from a renewable resource and can be recycled.