The casting process creates metal components by pouring molten metal into a mold cavity created from a patterned model. A casting pattern generally helps to reduce the risk of production delays, defects, and other issues that could disrupt a particular casting process.

Several different types of casting patterns can produce a wide range of components, from small castings to mass production systems. Each of these molding process has its unique requirements when it comes to patterns, as well as advantages and disadvantages. It is important to understand the differences between the various casting methods and how such patterns play in the process.

Single Piece Pattern or Solid Pattern

Single piece pattern, also called a solid pattern, begins by creating a single mold, or pattern, for the part. However, it is best used for castings with simple shapes, simple geometrical shapes, or simple rectangular blocks under a small-scale production.

This type of pattern is placed inside a mold box and filled with a special type of casting sand. The sand is then packed tightly around the pattern and allowed to harden.

The sand should also be cured with a suitable catalyst to reduce the risk of defects in the casting. The curing process ensures that the sand forms a strong mold to support the molten metal.

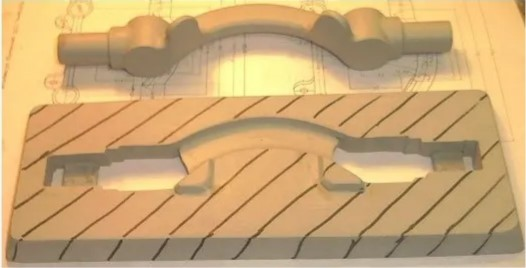

Two-Piece Pattern or Split Pattern

Split patterns are divided into two or more parts of a piece pattern. This process is used when producing large castings, and a single pattern is too large or complex to be cast in one piece. The split pattern is then assembled and used to create the finished product.

The process begins by creating a pattern consisting of two or more pieces. This pattern is then used to create a mold, typically made of sand.

Split patterns are often used in sand casting but can be used with other casting techniques. The parting surface where the split piece pattern comes together is usually indicated on the flat or irregular surface of the pattern.

Follow Board Pattern

The follow board pattern is created from a board marked with a pattern. This pattern is typically a sketch of the item that needs to be cast. Once the pattern is created, it is transferred to a wooden board, which is used to create the casting.

It allows for an exact replica of the item to be created. The follow board pattern is used to create the exact shape and size of the item, ensuring that it is the same as the original item.

The wooden board is marked with a line that indicates the outline of the item that needs to be cast. This line is referred to as the “follow line.” The follow line is then used to guide the casting process.

Multi-Piece Pattern

The multi-piece or segmental pattern uses a three-piece pattern typically made from wood, plastic, or metal. Each pattern is designed to create a specific part of the final casting. Once all the patterns have been created, they are assembled to create a complete pattern.

The loose pieces must be assembled to create the full pattern. Its assembly process is important to ensure the loose pieces fit together correctly and create a pattern that accurately reflects the desired end product.

The multi-piece pattern allows for more intricate shapes since the individual pieces can be shaped and contoured in any way.

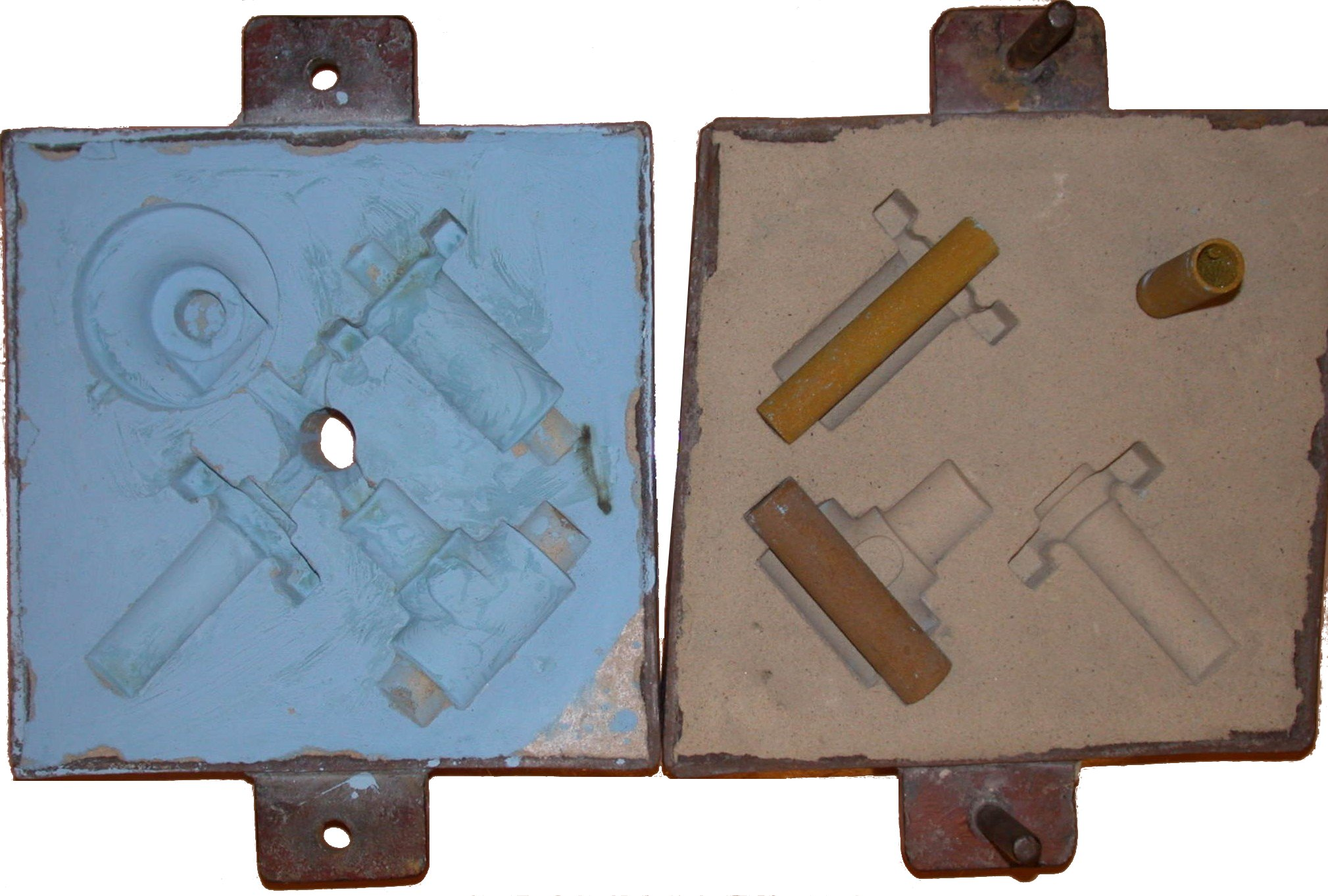

Match Plate Pattern

A match plate pattern is split into two loose patterns, which are then fit together on the match plate or metallic plate. The two pieces are then securely clamped together using dowel pins. The two pieces are then securely clamped together, and the molten metal is poured into the mold.

This is beneficial since large castings require much material to be poured into the mold. The two-piece mold also helps ensure that the two-piece pattern fits perfectly, resulting in more consistent casting quality.

Match plate pattern is commonly used for large castings, such as steam engine blocks and other large components.

Gated Pattern

To create a gated pattern, a patternmaker will use a die and a pattern plate in a molding process that is hollowed inside. For a more modern gated pattern, manufacturers use molding machines.

The gate also helps control the pressure of the material as it is poured into the pattern. It efficiently creates one or more patterns in a single casting process.

Gated pattern processes require a high level of skill and precision. A good patternmaker must know about the material and the process to create the best possible pattern. They must also be able to use the pattern of multiple components in combination with other tools and techniques to create the desired result.

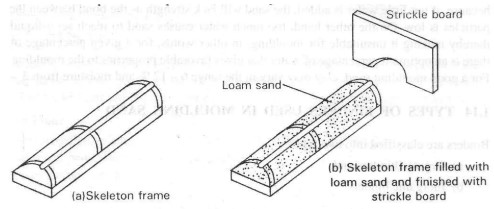

Skeleton Pattern

A skeleton pattern is another pattern in casting used to create the shape of a hollow object, such as a container or floor welding, or to create an internal form for a complex shape, such as a turbine blade.

Skeleton patterns are created by first constructing the object from a temporary material like wood or metal. The shape is then transferred onto the core and the cope. The core is cut out, and the cope is fitted onto the core. The skeleton pattern is then placed in a mold box, and the sand is packed around it.

When using a skeleton pattern, it is important to ensure that the core is properly placed in the mold and that the gating system is designed to properly direct the liquid metal into the mold.

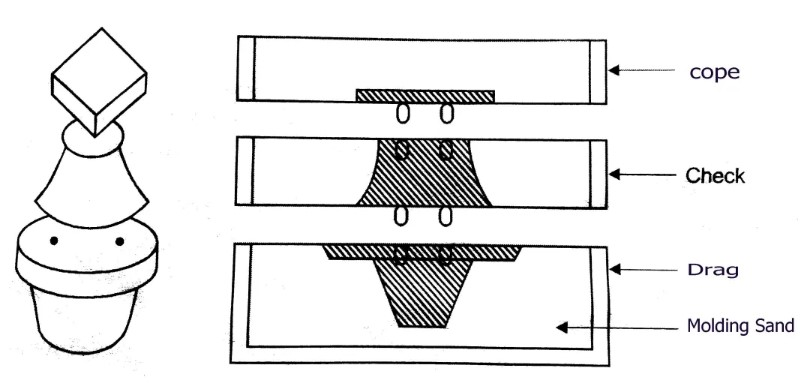

Cope and Drag Pattern

The cope and drag pattern is one of the most commonly used metal casting methods. In this process, the cope is placed on top of the drag, and liquid metal is poured into the flat surface between them. The cope and drag pattern forms the desired shape as the metal cools and solidifies.

Cope pattern is usually made of wood or plastic and are used to create the upper half of the casting. The pattern is designed to fit the shape of the desired casting and is used to create a negative impression of the desired shape.

A drag pattern is made of resin, sand, or metal, typically used to create the lower half of the casting. The drag pattern is made to fit the bottom half of the casting and is used to create a positive impression of the desired shape.

This positive impression is then filled with liquid metal, which is cooled and solidified to form the lower half of the casting.

Shell Pattern

In a shell pattern, the mold is created by packing the sand around a wax or plastic pattern of the desired finished shape. The wax or plastic pattern melts away, and the liquid metal is poured into the mold, filling the space left by the melted pattern.

The shell pattern is a full-scale model of the desired casting, made of wood, plastic, or metal with a hollow-shaped structure. This pattern is then used to create a sand mold with the desired shape by pressing the pattern into a box of dry sand.

The sand is then compacted and hardened to create a negative impression of the shell pattern. It allows for obtaining hollow-shaped structure with thin walls, which can be difficult to achieve with other casting processes.

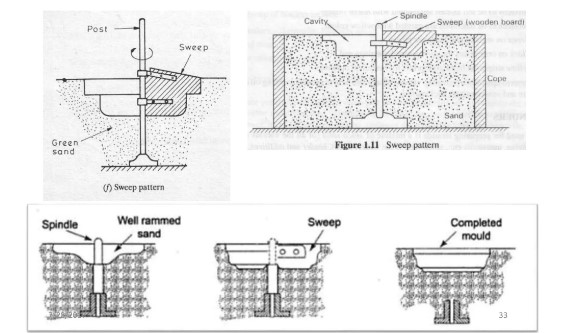

Sweep Pattern

This technique is used to create components with complex geometries or contours. The sweep pattern involves pouring molten material into the mold in a sweeping motion. This motion creates a more uniform thickness and fills any intricate details of sweep patterns.

The sweep pattern comprises a wooden board, a spindle base, and a casting material. The wooden board acts as the base of the pattern, while the spindle base supports the pattern wheel. The pattern wheel is mounted in a vertical direction on the spindle base and is used to guide the casting material.

Common Materials Used for Creating The Pattern Material

Wax

Wax is a popular material used in creating a pattern due to its versatility and ease of use.

The most common type of wax used in casting is lost wax. This type of wax is a specially formulated wax that is designed to melt away during the casting process and leave a

Sand

Sand is a very common material, so it is widely available and affordable compared to other materials. It is also straightforward to work with, making it an ideal choice for any types of patterns. The grains of sand are small enough to be shaped and manipulated into intricate shapes and designs.

Metal

Metal is well-suited for casting because it is strong, durable, and can withstand high temperatures. It also has excellent thermal conductivity, making it ideal for uniform cooling during the casting process.

Wood

Wood is one of the most commonly used materials for creating casting patterns. It is relatively easy to work with and is relatively inexpensive. Wood patterns can be used for simple parts like pipe fittings and brackets. However, wood is not suitable for intricate or complex shapes.

Foam

Foam is another material that is often used for creating patterns. It is lightweight and easy to work with. However, foam is not as strong or durable as other materials, so it is unsuitable for parts requiring a high degree of strength or durability.