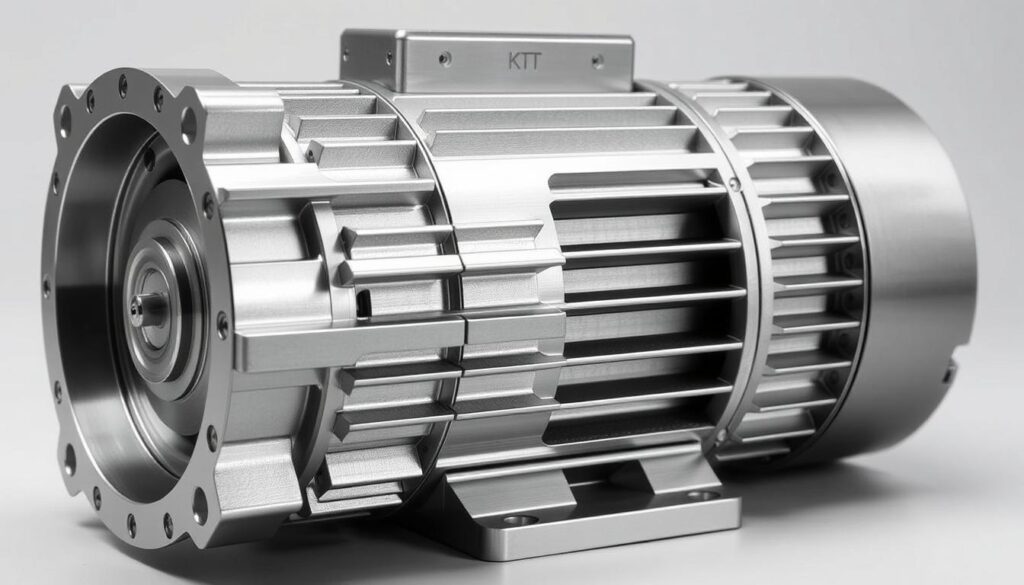

At KT-FOUNDRY, we know how crucial custom CNC machining is for car parts. We make everything from engine parts to interior trim. Our advanced CNC machines help us create motor housings that fit our clients’ exact needs.

We serve many industries, from cars to aerospace. Our clients need precision and reliability in their motor housings. That’s why we’ve built a top-notch CNC machining setup. We make high-quality electric motor housing, motor casing, and more.

Key Takeaways

- KT-FOUNDRY specializes in custom CNC machined solutions for electric motor housings across diverse industries

- Our expertise covers a wide range of automotive parts, including engine, transmission, suspension, and more

- We leverage state-of-the-art CNC machining to deliver tailored motor housing solutions

- We understand the importance of meeting unique industry requirements for motor housing design, motor housing materials, motor housing manufacturing, and motor housing maintenance

- Our commitment to quality and innovation ensures our clients receive the highest-performance electric motor housing components

Versatility of CNC Machining for Electric Motor Housings

At KT Foundry, we know how crucial the right materials are for electric motor housings. CNC machining lets us make top-notch motor housings from many materials. Each material has its own benefits to fit our clients’ needs.

Materials for CNC Machined Motor Housings

Aluminum is a top pick for electric motor housing materials. It’s light but strong, and it resists corrosion well. This makes it perfect for places where weight and corrosion matter a lot.

Stainless steel is great for motor housings that need to be very strong and resistant to corrosion. It’s often used in tough environments or where the motor needs to be sterilized often. This keeps the motor working well for a long time.

Titanium is another standout material for electric motor housings. It’s incredibly strong for its weight and is safe for use in the body. This makes it ideal for high-end, light applications where top performance is key.

We also work with engineering plastics like POM and PEEK. These materials are light and resist corrosion well. They can be customized to meet specific industry needs.

Our team at KT Foundry works with clients to find the best electric motor housing material for their needs. We aim for the perfect mix of performance, durability, and cost.

Custom CNC Machining Process for Electric Motor Housings

At KT-FOUNDRY, we have a custom CNC machining process for electric motor housings. We start by working closely with our clients. This helps us understand their design goals and performance needs.

We then create detailed prototypes for evaluation and testing. Our advanced CNC machining equipment lets us make these prototypes quickly. This means our clients get a fast turnaround.

Prototyping and Design Evaluation

After the design is set, we offer various surface treatment options. These include anodizing, polishing, powder coating, laser engraving, and custom graphics. These treatments improve the durability and look of the motor housings.

This lets our clients adjust the appearance and function of their electric motor housings. They can make sure they meet their specific needs.

Surface Treatments

We keep strict quality control measures throughout the process. This includes checks on dimensional accuracy, material testing, and quality inspection reports. It ensures our CNC machined electric motor housings are of high quality.

This focus on quality means our clients get motor housings that meet or exceed their expectations.

Quality Control and Testing

Our expertise in custom CNC machining, prototyping, surface treatments, and quality control helps us. We deliver electric motor housings tailored to each client’s needs. This ensures optimal performance and longevity.

“At KT-FOUNDRY, we take pride in our ability to provide custom CNC machined solutions that meet the exacting requirements of our clients in the electric motor industry.”

Conclusion

At KT-FOUNDRY, we focus on custom CNC machined solutions for many industries. We use our knowledge in materials, design, and manufacturing to create electric motor housings. These housings are not just high-performing but also look great and last long.

We work with our clients to meet their specific needs. Whether it’s special materials, detailed designs, or custom features, we aim to go beyond their expectations. Our goal is to make their products stand out.

We’re dedicated to quality, innovation, and making our customers happy. This has made us a reliable partner for companies looking for top-notch CNC machined motor housings. We’re proud to turn our clients’ ideas into real, high-quality solutions that make their products unique.

We keep improving by investing in new technologies and refining our methods. This keeps us ahead in the industry. It helps our clients reach their goals and stay competitive.

Looking ahead, we’re excited to explore new possibilities in CNC machined electric motor housings. Our commitment to excellence and innovation will keep us delivering custom solutions that impress our clients. We aim to be the top choice for custom CNC machined components.

FAQ

What industries does KT-FOUNDRY serve with custom CNC machined motor housings?

KT-FOUNDRY offers custom CNC machined solutions for many industries. They focus on high-precision electric motor housings. This includes parts for cars like engines, transmissions, and brakes.

They also make parts for the exhaust, interior, and exterior of vehicles.

What materials can be used for CNC machined electric motor housings?

KT-FOUNDRY uses various materials for electric motor housings. These include aluminum, stainless steel, titanium, and plastics like POM and PEEK. They help clients choose the best material for their needs.

How does the custom CNC machining process for electric motor housings work at KT-FOUNDRY?

At KT-FOUNDRY, the process starts with understanding the client’s goals and needs. They create prototypes for testing and use advanced CNC machines for quick production.

After finalizing the design, they offer surface treatments like anodizing and polishing. This improves the motor housings’ look and durability. They focus on quality control throughout the process.

What quality control measures does KT-FOUNDRY implement for their CNC machined electric motor housings?

KT-FOUNDRY has strict quality control for their motor housings. They check dimensions, test materials, and provide detailed inspection reports. This ensures their products meet high standards.

What are the key advantages of working with KT-FOUNDRY for custom CNC machined electric motor housings?

Working with KT-FOUNDRY means getting tailored electric motor housings. These are not just high-performing but also look great and last long. They work with clients to create solutions that go beyond expectations.