The structural integrity and performance of ductile iron castings are significantly evaluated by flexural strength, a critical benchmark in the foundry technology. At KT-Foundry, our expertise lies in producing grade 65-45-12 ductile iron, a ferrous metal with an impressive tensile strength of 65 ksi, yield strength of 45 ksi, and an elongation of 12%. The predominantly ferritic structure of ductile iron, whether as-cast or annealed, caters to machine components subjected to rigorous shock and fatigue loads. Our products exhibit remarkable hardness, with a Brinell hardness ranging between 131 and 220, ensuring cast iron durability appropriate for a plethora of heavy-duty applications. The optimal blend of elements such as carbon, silicon, and magnesium endows ductile iron with substantial mechanical properties, demonstrating its ability to withstand dynamic stresses and resist deformation, essential for modern engineering demands.

Key Takeaways

- Flexural strength is a crucial benchmark in evaluating the performance of ductile iron castings.

- Grade 65-45-12 ductile iron offers superior tensile and yield strength, along with impressive elongation.

- The predominantly ferritic structure of ductile iron is ideal for machine components subjected to rigorous loads.

- A unique blend of alloying elements contributes to ductile iron’s substantial mechanical properties and cast iron durability.

- KT-Foundry specializes in producing ductile iron castings to meet modern engineering demands across various industries.

Unveiling the Robustness of Ductile Iron Castings

At the heart of the foundry industry is the continuous pursuit of understanding and optimizing the cast iron material properties for a wide range of applications. With Ductile Iron Grade 65-45-12, we have established a baseline for reliability and performance, thanks to its unique material composition and adherence to stringent ASTM A536 standards. Using our foundry expertise, we customize this alloy to cater to the diverse needs of the engineering world.

Defining Ductile Iron Grade 65-45-12

Our ductile iron, made with precision and quality control, exhibits robust mechanical properties, with a tensile strength of at least 448 MPa, a yield strength of at least 310 MPa, and an elongation of 12%. These properties contribute to the material’s suitability for demanding industrial circumstances where components must withstand shock and fatigue loads. The cast iron material properties of this alloy are predominantly ferritic, providing enhanced durability and long-lasting performance.

Exploring the Unique Composition of Ductile Iron

Every ductile iron casting is an innovation due to its intricate alloy elements and how they work together. By customizing certain constituents, such as cerium, our ductile iron’s properties are tailored to suit specific application requirements. Additionally, the inclusion of elements like chromium, copper, and nickel introduces further resilience to the material’s characteristics, enabling it to perform reliably in the face of various operational challenges.

In conclusion, our continuous commitment to the advancement of continuous cast iron and foundry industry practices has led to the creation of a consistently robust and versatile ductile iron casting solution. The understanding and optimization of cast iron material properties, as well as the customization of alloy elements, empower our ductile iron castings to perform exceptionally under even the most challenging conditions.

Ductile Iron Castings: The Metallurgical Perspective

Ductile iron’s unique metallurgical characteristics provide a crucial advantage over conventional gray cast iron, combining the toughness of steel with the machinability needed for cost-effective manufacturing in engineering metals. The key to understanding ductile iron’s remarkable performance lies in the morphology of graphite and the precise matrix composition.

Understanding Graphite’s Role in Enhancing Strength

One of the defining features of ductile iron is the spheroidal graphite nodules dispersed throughout the matrix. These nodules impart high strength and ductility to the alloy, making it highly resistant to forces that may induce cracking. The unique graphite morphology ensures that ductile iron not only exhibits excellent machinability but also features a superior strength-to-weight ratio when compared to alternative engineering metals.

The Importance of Matrix Composition in Ductile Iron

In addition to graphite morphology, the role of matrix composition is paramount to the alloy’s mechanical properties. Balancing the proportion of pearlite and ferrite phases within the matrix is critical in achieving desired tensile and yield strengths while maintaining overall ductility and machinability. At KT-Foundry, our meticulous approach ensures that the material retains the optimal levels of combined carbon and graphite for maximum performance, reinforcing the robustness of our continuous cast ductile iron for various engineered applications.

| Matrix Phase | Tensile Strength | Yield Strength | Ductility | Machinability |

|---|---|---|---|---|

| Ferrite | Low | Low | High | High |

| Pearlite | High | High | Low | Low |

| Ferrite-Pearlite Mix | Medium | Medium | Medium | Medium |

In conclusion, the metallurgical characteristics of ductile iron, from graphite morphology to matrix composition, contribute to the alloy’s exceptional performance, shaping its adoption in various engineering sectors. At KT-Foundry, we continually strive to optimize these factors to ensure our products meet the highest standards while providing a durable, versatile, and cost-effective solution for our clients.

Industrial Applications of Ductile Iron Castings

The inherent strengths and versatility of ductile iron castings yield a spectrum of industrial applications. The automotive industry, infrastructure components, agriculture machinery, and construction applications are just a few sectors that greatly benefit from the ductile iron’s remarkable properties.

In the automotive industry, the alloy’s toughness is utilized for critical engine and suspension parts, where longevity and resistance to wear are paramount. Ductile iron’s tenacity transfers to applications in infrastructure, notably in water and wastewater systems. Its corrosion-resistant properties counteract the destructive effects of corrosion, ensuring long-lasting and durable infrastructure components.

The agriculture sector benefits from the material’s durability in tillage equipment, allowing for efficient and reliable operations. Construction applications employ the ductile iron for structural support elements, ensuring safety and stability in various projects. The diverse applicability of ductile iron castings underscores their adaptability and reliability in a broad range of sectors, making them a preferred material solution for KT-Foundry’s clientele.

Ductile iron castings are truly versatile, finding their fit in various industries and applications that require strength, durability, and resilience.

In conclusion, the numerous ductile iron benefits have made it an essential material for a multitude of applications across various sectors. Its unique combination of properties addresses specific needs for strength, durability, and longevity, setting it apart as a genuinely adaptable and reliable material solution.

Design Flexibility and Versatility of Ductile Iron

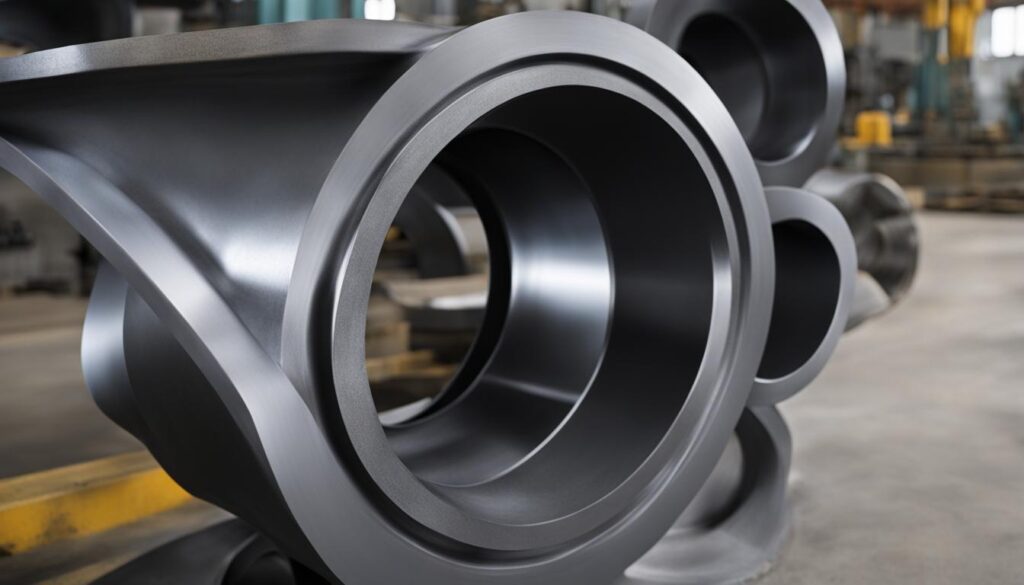

Ductile iron emerges as a prominent material choice for its adaptability and design versatility, enabling complex geometries and precision in casting that define the scope of its engineering applications. The material is widely utilized across numerous industries, proving its compatibility with diverse design challenges. KT-Foundry’s commitment to providing premium ductile iron castings empowers clients with customized solutions, ensuring the successful accomplishment of every project with precision and reliability.

Redefining Engineering Applications with Ductile Iron

Known for its remarkable abrasion resistance and capacity for energy dissipation, ductile iron provides a competitive edge in domains requiring impact resistance, such as automotive and agricultural machinery components. The capability to withstand repetitive stress challenges and maintain its integrity further solidifies ductile iron as an ideal solution for various engineering sectors. Its precision casting attribute enables our team at KT-Foundry to bring innovations to life, redefining the possibilities for engineering applications.

Highlighting Ductile Iron’s Diversity Across Industries

Ductile iron’s versatility spans across a spectrum of industries – from construction and infrastructure, where it serves as the preferred choice due to its resistance to environmental aggressors, to more demanding sectors like automotive and agriculture. The material’s design flexibility facilitates KT-Foundry’s ability to offer tailored solutions, catered to the specific needs of each project, making it a valued material option in the modern industrial landscape. Emphasizing the deeply rooted diversity of ductile iron, KT-Foundry’s offerings are a testament to the immense potential and value provided by this extraordinary metal.

FAQ

What is the flexural strength of ductile iron castings?

Flexural strength serves as a critical benchmark in evaluating the structural integrity and performance of ductile iron castings. At KT-Foundry, we produce grade 65-45-12 ductile iron, characterized by superior tensile strength of 65 ksi, yield strength of 45 ksi, and an elongation of 12%, making it suitable for heavy-duty applications.

What are the key elements of ductile iron grade 65-45-12?

Ductile iron grade 65-45-12 is defined by its robust mechanical properties, which include a tensile strength of a minimum of 448 MPa, yield strength of a minimum of 310 MPa, and an elongation of 12%. The specific blend of elements such as carbon, silicon, and magnesium, among others, endows ductile iron with these substantial mechanical properties, demonstrating its capacity to withstand dynamic stresses and resist deformation.

How does ductile iron’s metallurgical composition compare to gray cast iron?

Ductile iron’s metallurgical composition elevates it beyond the conventional properties of gray cast iron, combining toughness akin to steel with enhanced machinability for cost-effectiveness. Spheroidal graphite nodules dispersed in the iron confer upon it high strength and ductility, critical to resisting forces that induce cracking.

In which industries are ductile iron castings commonly used?

Ductile iron castings are used in various industries such as automotive, infrastructure, agriculture, and construction. In the automotive sector, ductile iron is utilized for critical engine and suspension parts. For infrastructure and construction, it’s used in water and wastewater systems, as well as structural support elements. In agriculture, the material’s durability is beneficial for tillage equipment.

What are the advantages of ductile iron in terms of design flexibility and versatility?

Ductile iron’s malleability and design agility enable complex geometries and precision in casting, which define the scope of its engineering applications. Its resilience against wear and capacity for energy dissipation confer advantages in domains requiring impact resistance, such as automotive and agricultural machinery components. Furthermore, ductile iron is a preferred choice in construction and infrastructure due to its resistance to environmental aggressors, offering a lifetime of service with minimal maintenance.