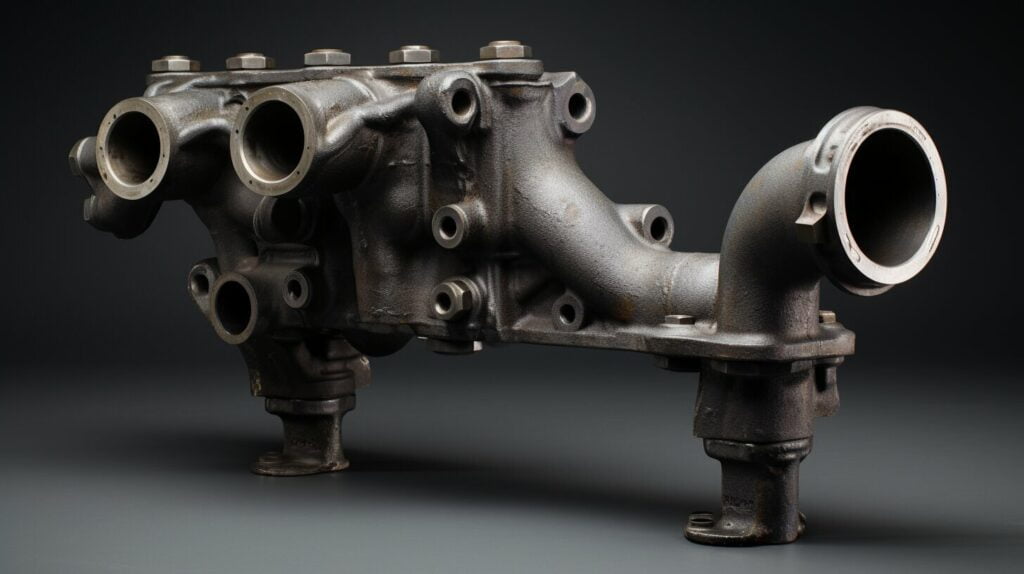

In the world of automotive engineering, the exhaust manifold is a critical component of a car’s exhaust system. It acts as a funnel, collecting waste gases from the engine’s cylinders and redirecting them to the exhaust pipe. Exhaust manifolds come in various materials, including steel, plastic, and aluminum.

However, if you want the best performance and durability, a cast iron exhaust manifold is the way to go. Cast iron is known to withstand extreme heat cycles and is corrosion-resistant, making it an excellent material for exhaust systems. An iron exhaust manifold can also increase performance, providing more horsepower and torque to your car’s engine.

Beyond its performance benefits, a cast iron exhaust manifold is the best choice when it comes to replacing stock manifolds. Many car manufacturers often use low-quality steel manifolds that tend to wear out quickly, leading to exhaust leaks and poor performance. By upgrading to a cast iron exhaust manifold, you can ensure the longevity and proper function of your exhaust system.

Overall, the exhaust manifold plays a crucial role in a car’s overall performance. It’s worth investing in a high-quality cast iron exhaust manifold to get the most out of your engine and enjoy a smooth, efficient ride.

Understanding Cast Iron Exhaust Manifolds

If you’re in the market for high-quality exhaust manifolds, cast iron is the way to go. Cast iron exhaust manifolds are designed to withstand extreme heat cycles, making them the ultimate choice for any engine.

Cast iron exhaust manifolds are made using a special manufacturing process that involves pouring molten iron into a mold. The result is a strong and durable product that can handle the intense heat generated by an engine.

How Cast Iron Exhaust Manifolds are Made

| Type of Manifold | Manufacturing Process |

|---|---|

| Cast Iron Exhaust Manifold | Molten iron is poured into a mold |

| Steel Exhaust Manifold | Steel tubing is bent and welded together |

| Iron Exhaust Manifold | Made from iron pipes, typically used in older vehicles |

Unlike steel or iron exhaust manifolds, cast iron exhaust manifolds are less prone to warping or cracking due to the high heat generated by the engine. This makes them more durable and less likely to require replacement.

Why Cast Iron Exhaust Manifolds are the Best Option

Cast iron exhaust manifolds are not only durable, but they are also corrosion-resistant, which means they will last longer than other materials. Additionally, they offer increased performance, resulting in more horsepower and better overall function of the exhaust system.

Installing your cast iron exhaust manifold requires special tooling and techniques to ensure proper fit and function. It is recommended that you leave this job to a professional mechanic to ensure a successful installation.

In conclusion, if you’re looking for a long-lasting, high-performance exhaust manifold, cast iron is the way to go. Its durability, resistance to corrosion, and increased performance make it the best option for any engine.

Cast Stainless Steel vs. Cast Iron Exhaust Manifolds

If you’re looking for a high performance exhaust manifold, you may be wondering if you should choose a cast stainless steel or cast iron one. Both materials have their own unique benefits that can make a difference in how your exhaust system performs. To help you decide which material is right for you, we’ve put together a handy table that lists the strengths of each option.

Cast Stainless Steel:

– Excellent resistance to corrosion

– Withstands high temperatures

– Won’t discolor from heat

– Won’t break down under extreme conditions

– Keeps its shape and won’t warp

Cast Iron:

– Excellent durability

– Can withstand high temperatures

– Won’t corrode from exposure to water or other elements

– resistant to breaking or cracking

– Not as expensive as stainless steel

Benefits of Upgrading to Cast Iron Exhaust Manifold

Switching to a cast iron exhaust manifold can significantly improve the performance of a vehicle. Here are some of the advantages of upgrading to a cast iron exhaust manifold:

| Benefit | Description |

|---|---|

| Increased Performance | A cast iron exhaust manifold can help to improve the airflow in the engine, resulting in increased power and acceleration. The increased exhaust flow also helps the engine breathe better, which can lead to better fuel economy. |

| More Horsepower | The improved airflow provided by a cast iron exhaust manifold can increase the horsepower of the engine. This is achieved by reducing the restriction on the exhaust system and allowing the engine to breathe more easily. |

| Improved Exhaust System | The exhaust manifold is an integral part of the exhaust system, and upgrading to a cast iron exhaust manifold can help to improve its function. This can lead to a quieter exhaust system and reduced emissions. |

| Durability | Cast iron exhaust manifolds are more durable than their steel counterparts. They are less likely to crack or warp due to extreme heat cycles, and they are also resistant to corrosion. |

| Longevity | Cars equipped with cast iron exhaust manifolds have been known to last longer than those with stock manifolds. This is due to the increased durability and resistance to corrosion of cast iron exhaust manifolds. |

It is important to note that there are many factors that can affect the performance of a car’s exhaust system, and upgrading to a cast iron exhaust manifold is just one of them. However, it is a highly effective way to improve the function of the exhaust system and get the most out of the vehicle.

Maintaining and Repairing Cast Iron Exhaust Manifold

Proper maintenance and repair of the cast iron exhaust manifold is crucial to ensure its longevity and optimal performance. Here are some tips and guidelines to follow:

Proper Maintenance

To maintain the cast iron exhaust manifold, regularly inspect it for signs of damage such as cracks, leaks, or loose fasteners. It’s important to keep the exhaust system clean by removing any dirt or debris that may accumulate over time.

Additionally, ensure that the bolts and nuts that secure the exhaust manifold are tightened to the recommended torque specifications. This will prevent the manifold from loosening and causing leaks or other issues.

It’s also recommended to periodically check and replace the exhaust gaskets as needed. Over time, gaskets can wear out or become damaged, causing exhaust leaks that can lead to decreased performance and increased emissions.

Dealing with Common Problems

If a crack is detected in the cast iron exhaust manifold, it’s important to address it promptly. Welding is a common repair method for cast iron exhaust manifold cracks, but it requires specialized equipment and skills. It’s recommended to seek the assistance of a professional welder experienced in repairing cast iron exhaust manifold.

When repairing a cast iron exhaust manifold, it’s important to ensure that the replacement gaskets and bolts are made from the same material as the original. Using incompatible materials can result in leaks, performance issues, and damage to the exhaust manifold and engine.

Protecting the Cast Iron Exhaust Manifold

To protect the cast iron exhaust manifold from corrosion, it’s recommended to apply a high-temperature paint or coating. This will help to prevent rust and other forms of corrosion that can lead to premature failure of the exhaust manifold.

When selecting a paint or coating, ensure that it’s compatible with the material of the exhaust manifold and the temperatures it will be exposed to. Some coatings may require multiple coats or periodic reapplication to maintain their effectiveness.

In conclusion, proper maintenance and timely repairs are essential for the longevity and optimal performance of the cast iron exhaust manifold. By following these guidelines, you can keep your vehicle’s exhaust system in top condition and ensure that it continues to deliver the performance and efficiency you expect.

Frequently Asked Questions about Cast Iron Exhaust Manifold

If you’re considering upgrading to a cast iron exhaust manifold or already have one installed in your vehicle, you may have some questions about maintenance, repair, and performance. Here are some frequently asked questions about cast iron exhaust manifold:

Can a cast iron exhaust manifold be welded?

Yes, cast iron exhaust manifold can be welded using the MIG welding process. However, it’s important to use the proper technique and tools to avoid further damage to the exhaust manifold. It’s recommended to seek the help of a professional mechanic for this type of repair.

How often should I maintain my cast iron exhaust manifold?

It’s important to regularly inspect and maintain your cast iron exhaust manifold, especially if you frequently drive in harsh conditions or off-road. It’s recommended to have it checked every 6 months or 10,000 miles, whichever comes first.

How do I repair a crack in my cast iron exhaust manifold?

There are several methods to repair a crack in a cast iron exhaust manifold, including welding, brazing, and epoxy. However, the best method depends on the extent of the damage and the location of the crack. It’s recommended to seek the advice of a professional mechanic for the best course of action.

How can a cast iron exhaust manifold improve performance?

A cast iron exhaust manifold is designed to improve airflow and reduce back pressure in the exhaust system, which can result in increased horsepower and improved performance. Additionally, because cast iron is more durable and resistant to corrosion than other materials, it can help improve the lifespan of your engine.

How do I choose the right cast iron exhaust manifold for my truck?

When choosing a cast iron exhaust manifold for your truck, it’s important to consider factors such as the size of your engine, the type of driving you do, and your budget. It’s recommended to consult with a professional mechanic or exhaust specialist to ensure you choose the right exhaust manifold for your specific needs.