Determining the Price Per Kilo for Cast Aluminium

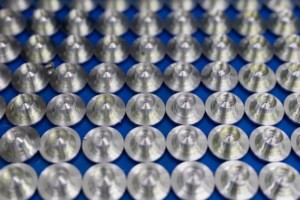

Cast aluminum costs between $1 and $1.10 per pound. Like any other material, cast aluminum can range its current prices per kilo for several reasons.

Cast aluminum costs between $1 and $1.10 per pound. Like any other material, cast aluminum can range its current prices per kilo for several reasons.

Anodizing, powder coating, and electroplating are some of the surface finishing options available for aluminum die castings. Each of these procedures offers a variety of benefits that set it apart from the others and help differentiate it from the others.

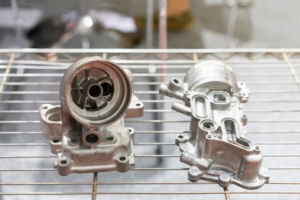

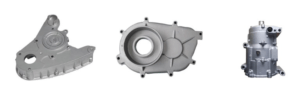

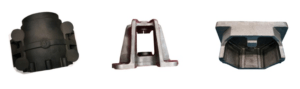

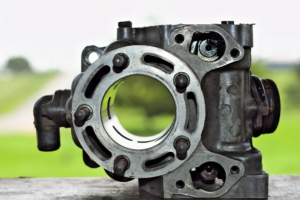

Die casting is a manufacturing process offers many advantages over other aluminum casting processes. This is mainly because it uses steel mold. It can produce complex shapes with high precision and consistency, high mass production rates and efficiency, and the ability to create parts with excellent strength and durability.

Though both are popular methods for aluminum castings, sand casting vs die cast parts have differences in almost all aspects of the process.

Whether you are a manufacturer looking to optimize your casting process or simply learning more about the two casting methods, this article will provide valuable insights into casting aluminum alloys.

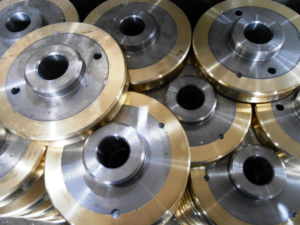

Aluminum castings are highly versatile and useful metals that are important in modern manufacturing. Its unique properties and wide range of applications make it popular in various industries and products.

The chemical composition makes it a highly durable and corrosion-resistant material. Its contact with air forms a thin aluminum oxide layer that adds an extra protection from further corrosion.

This manufacturing process involves injecting molten aluminum using die-casting equipment into a reusable steel mold or die. The result is a cost-effective, high-quality part with excellent mechanical properties and surface finish. This process is best for casting an aluminum alloy.

Stainless steel consists of iron, chromium, and other elements such as nickel, molybdenum, and nitrogen. In stainless steel, the chromium content serves as the passive layer of protection for better mechanical qualities of steel and corrosion resistance.

Stainless steel is a popular material used in many applications, from cookware to medical equipment. Stainless steel is non-magnetic.In some industries, it is essential to use non-magnetic materials to avoid interference with electronic equipment.

Stainless steel is one of the most popular and versatile materials used in the construction and engineering industries. It has many applications, from hand tools to industrial machinery and components. Manufacturers and consumers may combine the properties of stainless steel and other metals using stainless steel fasteners.

Stainless steel is a durable and versatile material used in various products and applications. It is composed of high-performance alloys and is widely used in different industries. Its versatility and strength make it an ideal choice for many applications.

Zinc alloys and stainless steel are two common choices that many individuals find themselves undecided between when it comes to selecting the appropriate metal for a casting component. Both of these components are metal alloys, which are formed by carefully combining metal with other alloys.

Die casting and sand casting are two popular methods used in producing aluminum castings. While both processes involve pouring molten metal into a mold, there are significant differences in how the molds are created and how the metal is handled. Though these popular methods have different approaches, the aluminum castings produced still have the same mechanical properties.

The manufacturing industry has experienced a paradigm shift in recent years with the emergence of 3D printing technology or metal additive manufacturing. This disruptive technology has opened up new avenues for creativity, design flexibility, and customization in the manufacturing process of metal parts.

The current prices for cast aluminum range from $1-1.10 globally. However, as with any material, the price per kilo of cast aluminum can vary depending on various factors.

Aluminum die casting is a highly precise and repeatable manufacturing process for producing high-quality cast aluminum. This manufacturing process involves injecting molten aluminum using high-pressure die-casting equipment into a reusable steel mold or die.

Aluminum die casting is a manufacturing process that involves the injection of molten aluminum alloy into a mold under high pressure. The molten aluminum is injected into a die, which is a mold made from two halves that are clamped together. The cavity inside the die is the exact shape of the part to be produced. The high pressure injects the molten metal to fill the die cavity, creating a precise and accurate desired shape of the part.

Investment casting, or lost wax casting, is a manufacturing process used to produce complex and intricate metal components with high dimensional accuracy, surface finish, and detail. It involves creating wax patterns or models of the investment cast coated with a ceramic shell to form a mold.

Stainless steel contains a minimum of 10.5% chromium by mass. This element gives stainless steel its characteristic corrosion resistance by forming a thin, adherent, and protective oxide layer on its surface when exposed to air. It also typically contains other elements, such as nickel, molybdenum, titanium, and copper, contributing to their specific properties and performance characteristics.

Stainless steels contains a minimum of 10.5% chromium, which makes it a highly corrosion-resistant metal. In addition to chromium, other stabilizing elements may be added to improve its properties, such as strength, ductility, and toughness.

Grey cast iron is a widely used material in various engineering applications. The American Society for Testing and Materials (ASTM) has established standards for the different grades of metal castings made from gray iron that a manufacturer or a consumer may use as reference.

The industrial and metalworking processes rely heavily on foundry and casting. These manufacturers create castings of any type of cast iron that can be used for different applications.

Ferrous and non-ferrous metals are both great for projects that require metal use. Both have their own advantages, but distinctions are critical for understanding their characteristics and applications. These metals were already used as the Iron Age and Copper Age started.

Ductile iron is a type of cast iron that has been engineered to have a higher tensile strength and ductility than traditional cast iron. It is an alloy of iron and other elements, including carbon and silicon, and has unique ductile iron compositions. Its density makes it a highly versatile material with a wide range of applications.

Ductile Iron is a versatile and cost-effective material used in many industries, such as automotive, oil and gas, and aerospace. It is known for its strength and durability, making it an ideal choice for various applications.

Cast steel is a type of metal composed of iron, carbon, and other elements. It is created through casting, where molten steel is poured into a mold and allowed to cool and solidify. Cast steel is often used in place of wrought iron and is known for its superior strength compared to cast iron.

Casting is a process that has been in use for many years. Cast steel and cast iron are two of the most common materials used in the casting process. Both metals offer good casting properties and potential performance benefits, but which material is best for a particular casting application?

The casting process is used in many industries to create objects from various materials. It involves pouring molten metal into a mold and allowing it to cool and take shape. There are a number of different metal casting techniques available, each with its own advantages and drawbacks.

Malleable iron is a form of iron that has been treated to become more ductile and resistant to breaking. It has a range of mechanical properties that make it suitable for a variety of applications.

The quality and performance of cast alloy steel components depend heavily on their precise specifications. The most crucial factor in choosing the correct alloy is knowing the exact specifications of the steel used. This includes the exact chemical composition, the mechanical properties, and the heat treatment.

Ductile iron, also called spheroidal or nodular iron, is a type of cast iron known for its high strength and durability. It has graphite substantially spheroidal in shape that gives excellent machinability.

Ductile iron is an exceptionally strong and versatile metal alloy used for centuries in various applications. Its high strength-to-weight ratio and excellent flexibility make it an ideal choice for many engineering projects. It is characterized by its high strength, toughness, and resistance to wear and fatigue.

Steel is an incredibly important material for the modern world. Its corrosion resistance, tensile strength, durability, and versatility make it perfect for use in a variety of industries and applications.

Can cast steel parts and cast iron rust? Yes. This is a question that is frequently asked by those who use cast steel parts for their industrial and commercial applications. While cast steel is highly resistant to corrosion, it is not completely immune to rust. This article will discuss what causes cast steel parts to rust and how to prevent it.

Cast steel is an alloy made up of iron, carbon, and other elements. It is a versatile material that has many uses in a variety of industries, from construction to automotive manufacturing. It can be formed into many shapes and sizes and is often used in the production of machine parts. These are also called cast irons, malleable iron, gray iron, or ductile iron.

Heat-treating cast steel is an important process for strengthening and improving its wear resistance. Cast steel is an alloy of iron and carbon, and it has been used for centuries to create a variety of tools, from swords to surgical instruments.

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.